An Informational Brief on Polymer Machining

One of the high-performance thermoplastics that AIP works with is NYLON: a PA, or polyamide. It is known for high strength, maintaining mechanical properties at elevated temperatures and chemical resistance. This polymer was first introduced by DuPont in the 1930s following extensive research on polyesters and polyamides. For this reason, polyamides comprise the largest family of engineering plastics with a wide range of applications. Typical applications of nylon include, but are not limited to: gears, industrial bearings, nozzles, sheaves and wear pads. Oftentimes, it replaces metal because it is very lightweight, weighing 1/7th as much as bronze.

Our latest machining guide discusses what goes into machining Nylon and how its considerations differ from other manufacturing options such as metal machining, injection molding, and 3D printing.

How does AIP approach nylon (PA) and its machining process? To start, we’ll explain the difference between machining nylon, a thermoplastic, and machining thermosets.

Machining Thermoplastics vs Thermosets

We’ve already said that nylon (PA) is a thermoplastic, but what does that mean exactly?

All polymers can more or less be divided into two categories: thermoplastics and thermosets. The main difference between them is how they react to heat. Thermoplastics like nylon, for example, melt in heat, while thermosets remain “set” once they’re formed. Understanding the technical distinction between these types of materials is essential to CNC machining them properly.

The table below outlines the main properties of thermoplastics versus thermosets:

Thermoplastics

|

Thermosets

|

- Good Resistance to Creep

- Soluble in Certain Solvents

- Swell in Presence of Certain Solvents

- Allows for Plastic Deformation when Heated

|

- High Resistance to Creep

- Cannot Melt

- Insoluble

- Rarely Swell in Presence of Solvents

|

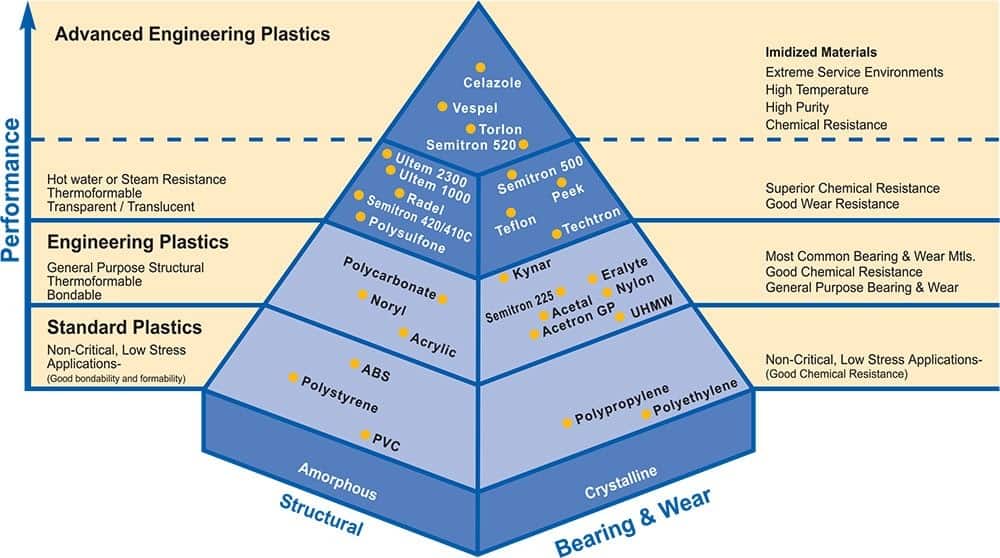

From there, thermoplastics are categorized into amorphous or crystalline polymers per the figure below:

Based off of the chart, nylon is a semi-crystalline, high purity engineering thermoplastic, meaning its molecular structure is highly ordered. The highly ordered structure of a crystalline structure is what lends the polymer to strength and rigidity. Generally speaking, crystalline structures are opaque since the structure tends to reflect light. Here at AIP, we machine several different grades of nylon for multiple industrial applications.

Properties & Grades of Machined Nylon (PA)

As a thermoplastic, nylon offers industrial-grade resistance to pH changes due to varying thermal conditions, as well as solvent-resisting capabilities. This can be an advantage in petrochemical industries where fluoropolymer parts are in contact with or exposed to bursts of gases, oil or detergents.

It should also be noted that nylon (PA) is known for its high degree of crystallinity, which results in a stronger and strain-resisting component. Furthermore, applying nylon reduces the need for heavy lubrication, and dampens sound and eliminates galling, corrosion and pilferage problems.

There are two common grades of nylon that should be mentioned for their properties and applications, Nylon 6 and Nylon 6/6. They can be used interchangeably for various applications, but there are some property differences to note:

Nylon 6:

Nylon 6 is usually produced in two forms: for textile use and high-strength types for industrial uses. It is usually formed into filament yarns and staple fiber. Most of the time this nylon can be found in tire cords, parachutes, ropes or industrial cords. In comparison to Nylon 66, Nylon 6 has these benefits:

- A lower density

- Better toughness

- Better surface appearance

- Lower processing temperature

In times of war, there are often significant advancements in material usage, weaponry, and machinery. World War II was no different. Plastics entered the scene during World War II, starting with the replacement of metal parts for rubber parts in U.S. aircraft after Japan limited metal trade with the United States. Following that, plastics of higher grades began to replace electrical insulators and mechanical components such as gears, pulleys, and fasteners. Aircraft manufacturers began to replace aluminum parts with plastics as they were lighter and thus more fuel efficient than aluminum.

Nylon 6/6:

Much like Nylon 6, Nylon 6/6 has many industrial applications, from thin walled components to large thick-walled bearings. It is also an outstanding candidate for metal replacements. Compared to Nylon 6, Nylon 6/6 has the following advantages:

- Higher temperature resistance

- Higher strength

- Higher stiffness

- Lower moisture absorption

- Better abrasion resistance

Besides Nylon 6 and Nylon 6/6, AIP offers wide-ranging machining expertise of Nylon® and Polyamide grades that provide different strength, thermal stability, and corrosion resistance. Our decades of experience with high-performance specialty plastics and thermoplastics can help you select the best grade of nylon for your application.

Machining Nylon (PA)

Annealing is a heat treatment that changes the properties of a material to make it easier to machine by increasing ductility and reducing hardness in the material. The process of annealing and stress-relieving nylon reduces the likelihood of surface cracks and internal stresses occurring in the material. For more information on AIP’s annealing processes for nylon and other materials, reference our annealing guide.

Annealing Nylon

Annealing is a heat treatment that changes the properties of a material to make it easier to machine by increasing ductility and reducing hardness in the material. The process of annealing and stress-relieving nylon reduces the likelihood of surface cracks and internal stresses occurring in the material. For more information on AIP’s annealing processes for nylon and other materials, reference our annealing guide.

Machining Nylon

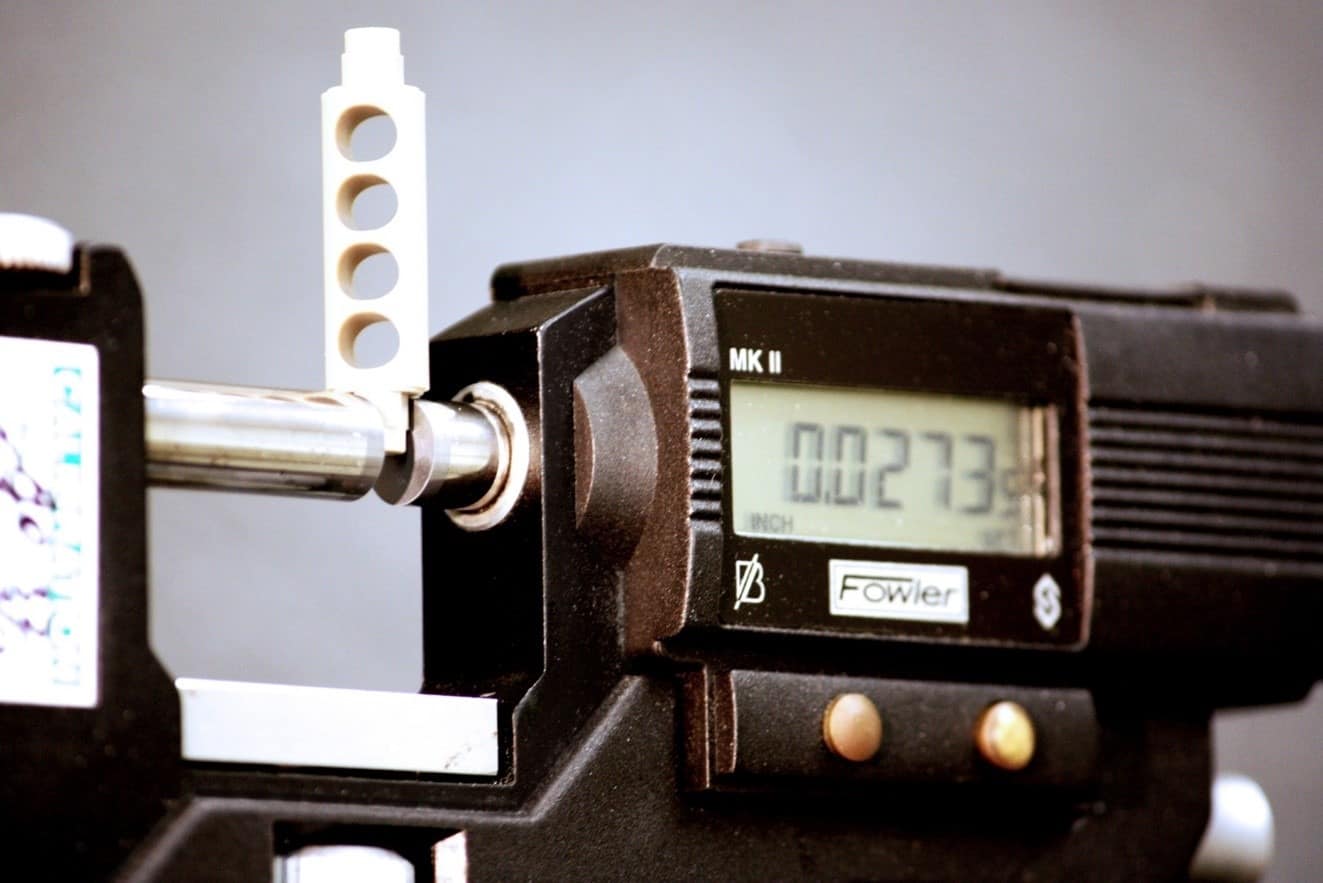

Nylon offers ease of machining and tight tolerances due to its inherent strength, toughness and dimensional stability. Machining Nylon isn’t too different from machining metals as a result of this; pretend you’re machining brass. Unlike metal, though, nylon (like all thermoplastics) will deform if you hold it too tightly as it yields easily. We generally recommend Tungsten Carbide Alloy Tooling. Also, keep the part very cool and support it well. We also suggest non-aromatic, air-based coolants to achieve optimum surface finishes and close tolerances. Coolants have the additional benefit of extending tool life as well.

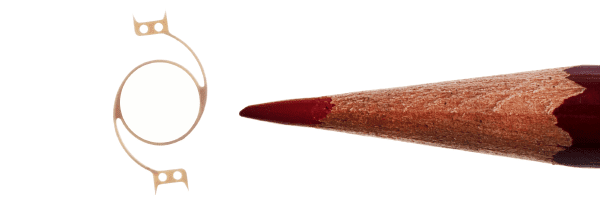

Case in point, Nylon (PA) can be manufactured into industrial equipment components that may include piping and tubing, valves, gears, nozzles, and wear pads—among many other formats. It can also be combined with other materials, helping customers innovate and create new product classes with utility that exceeds its original applications.

Preventing Contamination

Contamination is a serious concern when machining polymer components for technically demanding industries such as aerospace sciences. To ensure the highest level of sanitation down to the sub-molecular level, AIP Precision Machining designs, heat-treats and machines only plastics, with any sub-manufactured metalwork processed outside our facility. This allows us to de-risk the process from metallic cross contamination.

Nylon (PA) Polyamide Machining Guide: Supportive Information

AIP Nylon Variants Guide

Explore Our Inventory

or request a quote here.

Among the many polymer materials we machine at AIP,

Among the many polymer materials we machine at AIP,