PART SUMMARY:

One of the high-performance thermoplastics that AIP machines is Polyetherimide (PEI), known by its tradename ULTEM. Due to its weight-saving properties, high chemical and hydrolysis resistance and tensile strength, ULTEM is popular across several industries: Automotive, aerospace and defense, electrical and electronic market, medical and life sciences and industrial applications and appliances. Read on to learn about what this incredible polymer can do!

MATERIAL PROPERTIES:

Polyetherimide (PEI) is an amorphous thermoplastic. Polyetherimide was developed to provide sufficient flexibility and good melt processability while maintaining excellent mechanical and thermal properties.

Key properties of ULTEM PEI include:

- Handling at temperatures up to 340°F (171°C)

- Heat Resistance

- Flame Resistance

- Chemical Resistance

- High Rigidity

- Highest Dielectric Strength

- Hydrolysis Resistance

- Low Thermal Conductivity

ULTEM Applications

As mentioned previously, ULTEM is a highly sought-after thermoplastic for weight-saving capabilities in aerospace components to reusable autoclave sterilizations in medical applications. However, it’s most commonly used in high voltage electrical insulation applications.

Common uses include:

- Analytical Instrumentation

- Dielectric Properties Required

- Electrical Insulators

- High Strength Situations

- Reusable Medical Devices

- Semiconductor Process Components

- Structural Components

- Underwater Connector Bodies

So, what can this polymer do? Let’s take a closer look at how ULTEM (PEI) is applied in the Aerospace & Defense, Medical & Life Sciences and Specialized Industrial markets:

WHAT CAN ULTEM DO FOR AEROSPACE & DEFENSE?

In the Aerospace & Defense Industry, ULTEM is often applied to aircraft components for weight reduction in place of metal parts. Additionally, since it has a high thermal resistance rating, polymer components have the benefit of evading radar detection in military aircraft.

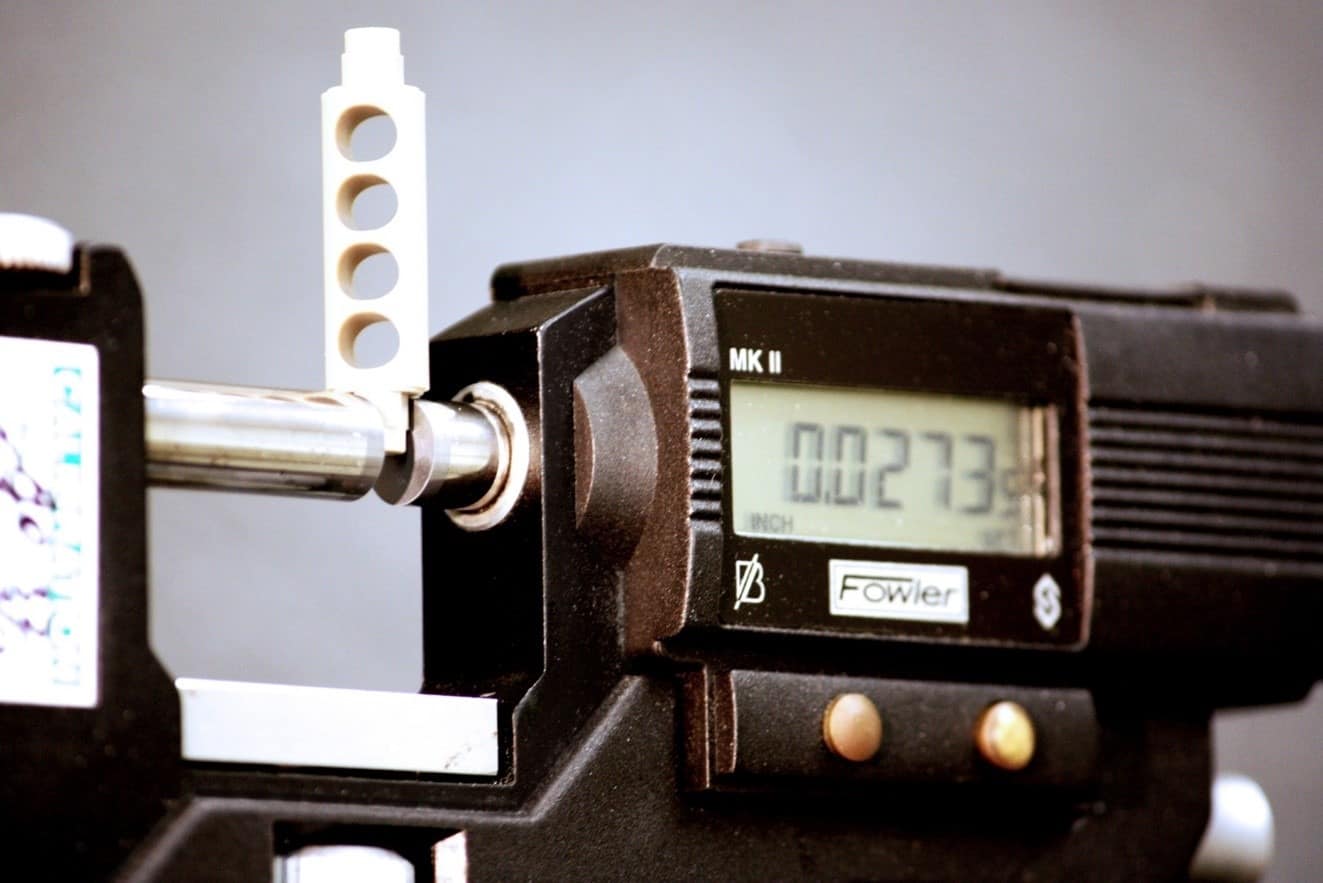

AIP machines ULTEM 1000 & ULTEM 2300

ULTEM 2300 is a 30 percent glass filled version of virgin ULTEM 1000. The addition of glass increases ULTEM 1000’s dimensional stability by almost three times.

For over three decades, AIP has provided flight control, fuel system, interior, engine and aerodynamic-related ULTEM components for various aircraft OEM and MRO providers worldwide. As this industry continues to expand, evolve and innovate, the demand for high-performance materials like ULTEM contribute significantly to streamlined operations.

WHAT CAN ULTEM DO FOR MEDICAL & LIFE SCIENCES?

In the Medical Industry, biocompatibility and sterilization are paramount to medical instruments and implants. ULTEM is often a popular choice in this sector due to its resistance to chemicals and lipids. Polyetherimide also withstands dry heat sterilization at 356°F (180°C), ethylene oxide gas, gamma radiation and steam autoclave.

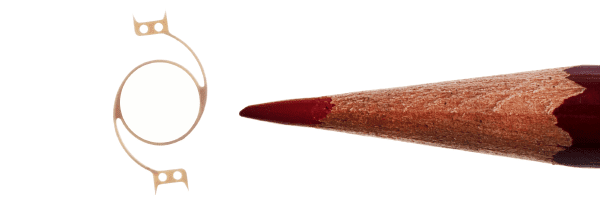

Some popular medical applications include disposable and re-usable medical devices and medical monitor probe housings. These could be surgical instrument handles and enclosures or non-implant prostheses. It gets extensive use in membrane applications due to its separation, permeance and biocompatible properties.

WHAT CAN ULTEM DO FOR SPECIALIZED INDUSTRIAL Sectors?

At AIP, we precision machine ULTEM for many specialized industrial applications as well: automotive, electrical and metal replacement, to name a few. Despite the diversity of these industrial applications, we have the inventory and machining capabilities to provide solutions for any project specifications.

PEI is most often used in electrical and lighting systems in the automotive market for its high heat resistance, mechanical integrity and strength. Principal automotive applications include: transmission parts, throttle bodies, ignition components, thermostat housings, bezels, reflectors, lamp sockets and electromechanical systems.

The electrical and electronic markets demand high heat resistant materials. ULTEM is an excellent choice for applications such as electrical circuit boards, switches, connectors, electronic chips and capacitors.

As discussed previously, thermoplastics like ULTEM often replace metal parts in industrial applications. For this reason, it’s often used in housewares, especially fluid handling systems. Some of these applications are: HVAC equipment, microwave cookware, steam and curling irons, dual-ovenable trays for food packaging that meets FDA food packaging requirements.

What can AIP Precision Machining do for you?

From concept to completion, our team of engineers will work with you to realize the final product. With some of the fastest lead times in the industry, our unrivaled technical experts we can tackle your polymer challenges.

What Can This Polymer Do? Supportive Information

Medical Sector Biomaterials Guide

Aerospace Sector Materials Guide

Aerospace Case Study: Weight-saving Polymers