In aerospace engineering, the search for materials that can meet stringent performance criteria like being light weight, having thermal resistance, and providing electromagnetic interference (EMI) shielding is relentless. Historically, metals were the go-to choice, but their limitations in weight and corrosion resistance posed significant challenges. Enter Magnetic Polymer Nanocomposites In Aerospace – a game-changer in material science.

Polymer nanocomposites, particularly magnetic polymer nanocomposites (MPNs), have emerged as the leading option in addressing these challenges. Their unique composition – a polymeric matrix reinforced with nanometric-sized fillers – gives them a blend of properties from both polymers and magnetic materials. This synergy is crucial for aerospace applications where every ounce matters, and every degree of thermal resistance can be the difference between success and failure.

| Section | Key Takeaways |

| MPNs Composition and Characteristics | Description of MPNs, their polymeric matrix, and magnetic nanoparticles. Importance in reducing aircraft weight and enhancing performance. |

| Synthesis Methods | Various methods like molding, coprecipitation, and in situ precipitation used to fabricate MPNs. Each method’s advantages and unique features. |

| Characterization Techniques | Importance of characterizing MPNs using techniques like Computational Modeling, AFM, TEM, and Raman Spectroscopy. |

| Aerospace Applications | Applications of MPNs in EMI Shielding, Coatings and Paints, and Structural Health Monitoring. Their role in enhancing safety and efficiency. |

| Future Research Trends | Focus on eco-friendly approaches, industrial scalability, and enhanced functionalities in MPNs. |

Magnetic Polymer Nanocomposites: Composition and Characteristics

Magnetic Polymer Nanocomposites (MPNs) are formed by embedding magnetic particles, typically in the nanoscale range, into a polymer matrix. The matrix material, often a lightweight polymer, provides structural integrity, while the magnetic nanoparticles impart unique magnetic properties.

The matrix can vary widely, from common thermoplastics to high-performance polymers, each selected based on the desired balance of mechanical, thermal, and magnetic characteristics. The choice of magnetic particles, like iron oxide or nickel, is equally critical. These nanoparticles grant the MPNs their distinctive magnetic behavior, essential for applications like electromagnetic interference (EMI) shielding and sensor technology.

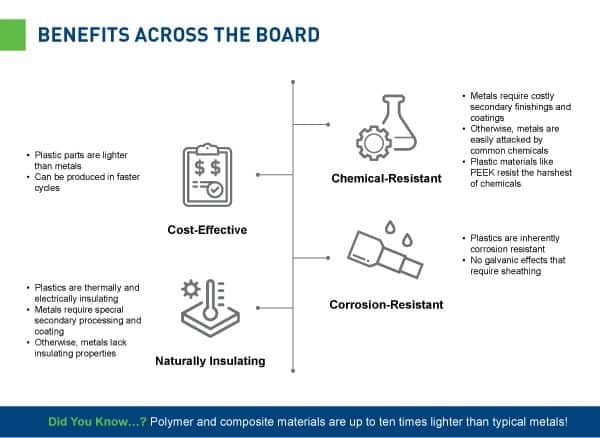

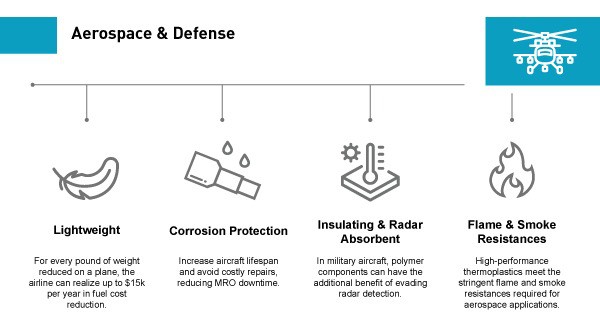

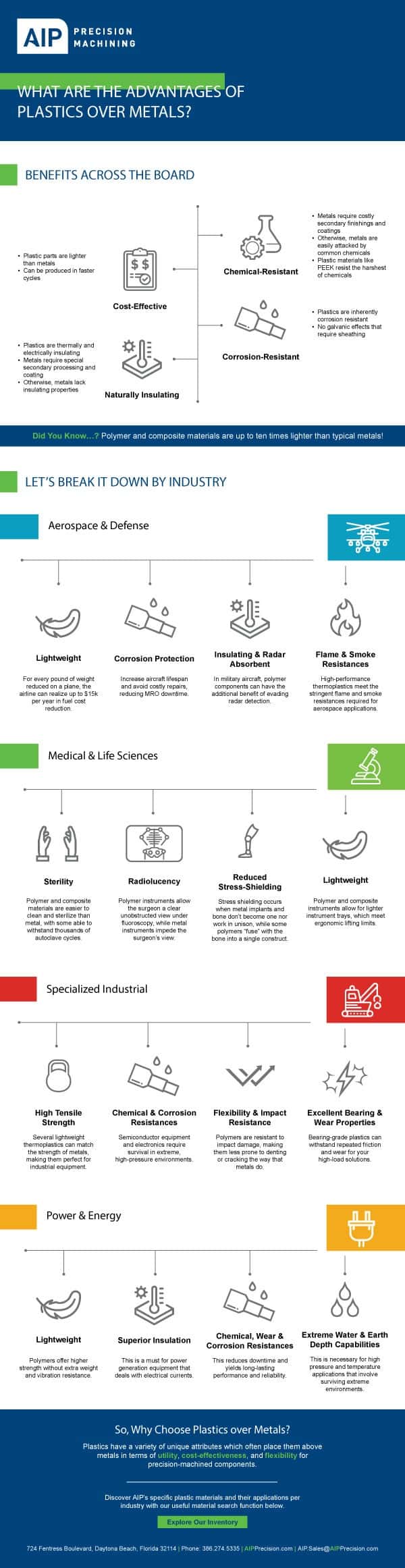

In aerospace, the impact of MPNs is profound. They contribute to reducing the overall weight of aircraft, a paramount goal in aerospace engineering. Lighter aircraft are more fuel-efficient, leading to cost savings and reduced environmental impact. Additionally, their enhanced performance characteristics, like thermal stability and corrosion resistance, make them ideal for the harsh conditions encountered in aerospace environments.

Synthesis of Magnetic Polymer Nanocomposites

The fabrication of MPNs is a sophisticated process, crucial to achieving the desired properties. Common methods include:

- Molding: This involves embedding magnetic nanoparticles into the polymer matrix during the molding process. It’s a direct and efficient method, suitable for large-scale production.

- Copolymerization and In Situ Precipitation: These techniques involve forming the polymer matrix around the magnetic particles. This results in a more uniform distribution of nanoparticles, enhancing the magnetic properties.

- Blending and Grafting: These are used to modify existing polymers, adding magnetic nanoparticles to the mix. The key here is achieving a homogeneous mixture to ensure consistent properties throughout the material.

Each method has its own set of advantages, ranging from ease of production to the degree of control over the final properties. The choice of method is dictated by the specific application requirements in the aerospace industry.

Characterization of Polymer Nanocomposites for Aerospace

Characterization is pivotal in understanding and refining the properties of MPNs. It involves a range of techniques:

- Computational Modeling: Used for predicting the behavior of nanocomposites under various conditions.

- Atomic Force Microscopy (AFM) and Transmission Electron Microscopy (TEM): These provide insights into the nanoscale structure of the composites.

- Raman Spectroscopy and X-ray Diffraction: Essential for understanding the chemical composition and crystalline structure.

- Thermal Characterization: Determines how the material behaves under different temperature conditions, critical for aerospace applications.

Characterization sets the stage for practical application. The real test of magnetic polymer nanocomposites lies in their performance in real-world aerospace applications. From shielding sensitive equipment to enhancing structural integrity, MPNs are making significant strides in aerospace technology.

Aerospace Applications of Magnetic Polymer Nanocomposites

In the aerospace industry, the applications of magnetic polymer nanocomposites (MPNs) are as varied as they are critical. These materials are increasingly employed in areas where traditional materials may fall short. Key applications include:

- Electromagnetic Interference (EMI) Shielding: MPNs are ideal for EMI shielding due to their magnetic properties. In aerospace, where electronic systems must operate without interference, these materials protect sensitive equipment from external electromagnetic fields.

- Coatings and Paints: MPNs are used in specialized coatings and paints for aerospace vehicles. These coatings provide not just aesthetic enhancements but also functional benefits like corrosion resistance, thermal stability, and improved aerodynamics.

- Structural Health Monitoring (SHM): With their inherent magnetic properties, MPNs are used in sensors embedded within aerospace structures for real-time monitoring. These sensors can detect stress, strain, and even micro-damage, enabling proactive maintenance and ensuring the integrity of the aircraft.

These applications demonstrate the versatility and indispensability of MPNs in modern aerospace design and maintenance. They offer a blend of lightweight construction with advanced functional properties, crucial for the evolving needs of the aerospace sector.

Future Research Trends in Magnetic Polymer Nanocomposites

The development of magnetic polymer nanocomposites is an active area of research, with several emerging trends:

- Eco-Friendly Approaches: A growing area of focus is the development of MPNs using sustainable and environmentally friendly methods. This includes the use of biodegradable polymers and eco-friendly synthesis processes.

- Industrial Scalability: Researchers are also working on methods to scale up the production of MPNs without compromising their quality and performance, making them more accessible for widespread aerospace applications.

- Enhanced Functionalities: Future research is likely to explore MPNs with multi-functional properties, such as self-healing or shape-memory features, expanding their application scope in aerospace engineering.

These trends indicate a bright and innovative future for MPNs in aerospace, with potential benefits extending into environmental sustainability and industrial efficiency.

Conclusions: The Future of Aerospace Materials

Magnetic polymer nanocomposites (MPNs) are not just an innovative material choice in aerospace; they are revolutionizing the industry. These composites blend the lightweight nature of polymers with the unique properties of magnetic particles, resulting in a material that is not only less burdensome in terms of weight but also superior in performance. From EMI shielding to structural health monitoring, MPNs are proving to be invaluable in enhancing the safety, efficiency, and functionality of aerospace applications.

As the aerospace industry continues to evolve, the role of MPNs is becoming increasingly crucial. With ongoing research and development, these materials are poised to unlock new possibilities, leading to aircraft that are more fuel-efficient, environmentally friendly, and capable of overcoming the stringent challenges of aerospace environments.

Partner with AIP Precision Machining for Aerospace Innovation

At AIP Precision Machining, we understand the importance of staying ahead in the dynamic field of aerospace engineering. Our expertise in precision machining and our commitment to innovation make us the ideal partner for exploring the potential of magnetic polymer nanocomposites in your aerospace applications. Whether you are looking to enhance your current systems or develop new solutions, our team is equipped to bring your vision to life with cutting-edge materials and state-of-the-art manufacturing techniques.

Contact AIP Precision Machining today to discuss how we can collaborate on your next aerospace project. Let’s work together to shape the future of aerospace technology.

Acknowledgment and Reference

This article was developed based on a research paper titled “Recent Trends in Magnetic Polymer Nanocomposites for Aerospace Applications: A Review.”

Our article aims to summarize and simplify the concepts and findings of their extensive work to make it more accessible for a general audience, particularly those in the engineering field. The full details, in-depth analysis, and comprehensive information are contained in the original research paper, which holds the complete set of data and findings. To access the full paper and for a more detailed understanding, please visit: https://www.mdpi.com/2073-4360/14/19/4084.