An Informational Brief on Polymer Machining

Since it was first polymerized in 1954 by Karl Rehn and Giulio Natta, polypropylene (PP) has become one of the leading polymer choices for a wide array of applications from automotive to commercial to medical.

Polypropylene plays a significant role in medical applications due to its high chemical resistance, lightweight, radiolucency and repeated autoclavability. Furthermore, medical grade PP exhibits good resistance to steam sterilization and moisture resistance. Disposable syringes, instrument or implant caddies and fluid delivery systems are the most common medical application of polypropylene. Other applications include medical vials, diagnostic devices, petri dishes, intravenous bottles, specimen bottles and surgical trays.

Want to learn more about the polymers we precision machine for medical applications?

Read Our blog |

AIP has over 35 years of experience machining complex components from thermoplastics like polypropylene. In this insightful technical brief, we will discuss what goes into machining polypropylene and how it differs from other manufacturing options such as metal machining, injection molding, and 3D printing.

Homopolymer vs Copolymer – What’s the Difference?

The two main types of polypropylene available on the market are homopolymers and copolymers. Although they share many properties, there are some differences that help guide machinists and engineers in choosing the right material for their PP application. For the purposes of this blog, we will briefly review the differences between PP homopolymer and PP copolymer.

| PP Homopolymer | PP Copolymer |

|

|

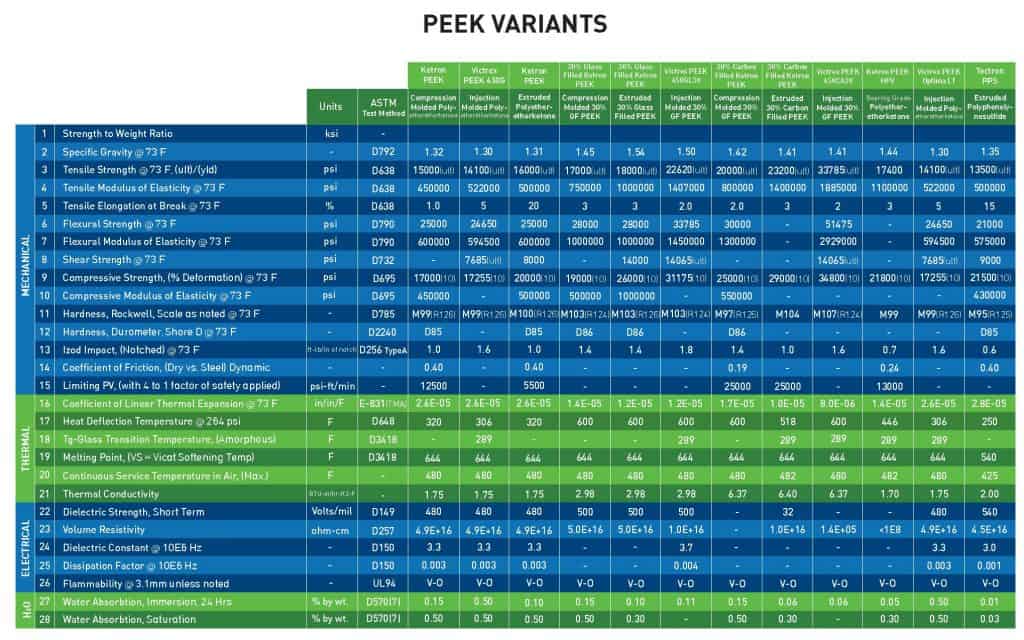

Properties of Polypropylene

Keeping information about the properties of a thermoplastic beforehand is always beneficial. This helps in selecting the right thermoplastic for an application. It also assists in evaluating if the end use requirement would be fulfilled or not. Here are some of the key properties of polypropylene:

Polypropylene is characterized by excellent chemical resistance in corrosive environments, resistance to cleaning agents and solvents and by a high heat deflection temperature.

It also has great dimensional stability and is fairly easy to machine. As noted above, it is available in heat-stabilized homopolymer and copolymer grades. At AIP, we machine POLYSTONE P, PROPYLUX HS and HS2, PROTEUS LSG HS PP from MCAM, TECAPRO MT and TECAFINE PP from Ensinger. Interesting to note is that both the PROPYLUX and TECAPRO heat stabilized PP grades are available in both standard and custom colors for medical sorting and sizing organization. Whatever your application, our machinists can help you in material selection, sizing and manufacturing techniques from concept to completion.

Melting Point of Polypropylene – The melting point of polypropylene occurs at a range.

Homopolymer: 160 – 165°C

Copolymer: 135 – 159°C

Density of Polypropylene – PP is one of the lightest polymers among all commodity plastics. This feature makes it a suitable option for lightweight\weight saving applications.

Homopolymer: 0.904 – 0.908 g/cm3

Random Copolymer: 0.904 – 0.908 g/cm3

Impact Copolymer: 0.898 – 0.900 g/cm3

Machining Polyproylene

Annealing Polypropylene

Due to its low annealing temperature, PP, like any polymer under heat and pressure, has a tendency to deform during machining. The annealing process at AIP greatly reduces the chances of these stresses occurring from the heat generated during machining PP and other polymers. Our machinists use computer controlled annealing ovens for the highest quality precision machining.

Machining Polypropylene

As a part of the polyolefin family, PP is semi-crystalline, which means that it can be machined at tight tolerances. We recommend non-aromatic, water-soluble coolants because they are most suitable for ideal surface finishes and close tolerances.

Bear in mind that polypropylene has variable levels of thermal expansion and will move a great deal with slight temperature changes. Some examples are pressurized air and spray mists. Coolants have the additional benefit of extending tool life as well.

Some companies machine both metals and plastics, which has detrimental outcomes for clients. Many past experiences have shown parts going to customer without cracks, only to develop cracks over time due to exposure to metal machine shop fluids. Be sure to use a facility like AIP that only machines polymers.

Preventing Contamination

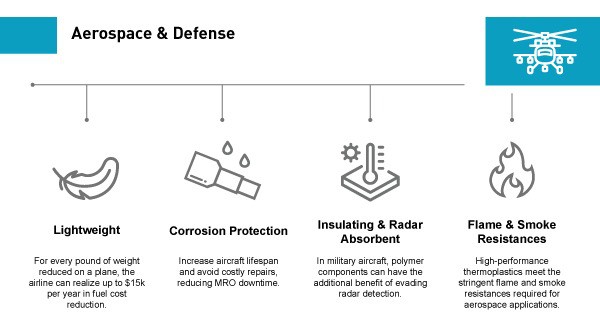

Contamination is a serious concern when machining polymer components for technically demanding industries such as aerospace and medical sciences. To ensure the highest level of sanitation down to the sub-molecular level, AIP Precision Machining designs, heat-treats, and machines only plastics with any sub-manufactured metalwork processed outside our facility. This allows us to de-risk the process from metallic cross contamination.

Polypropylene Machining Guide: Supportive Information

ISO 13485:2016 Certification

ISO 9001:2015 Certification

Need a machined part from medical grade polypropylene?

Talk to our team of expert engineers and machinists about your project needs and specifications.

Get a Consultation |

Among the many polymer materials we machine at AIP,

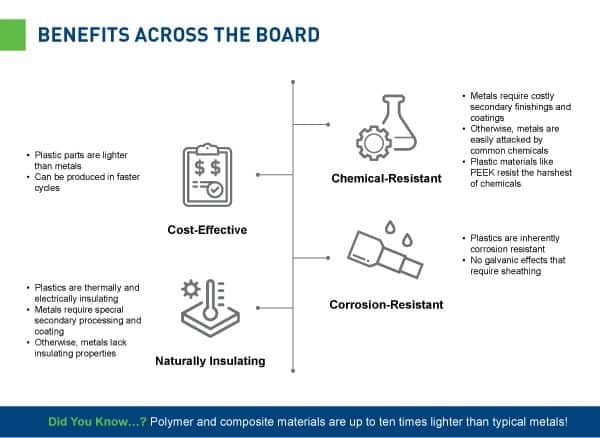

Among the many polymer materials we machine at AIP,  With 36+ years of experience in the industry, our dedicated craftsmen and ties to leading plastic manufacturers allow us to provide you with unrivaled knowledge and consulting in material selection, sizing, manufacturing techniques and beyond to best meet your project needs.

With 36+ years of experience in the industry, our dedicated craftsmen and ties to leading plastic manufacturers allow us to provide you with unrivaled knowledge and consulting in material selection, sizing, manufacturing techniques and beyond to best meet your project needs.