An Informational Brief on Polymer Machining

Among the many plastics AIP precision machines, PSU (Polysulfone) is a high-performance thermoplastic made from UDEL Resin. This particular thermoplastic is able to retain its properties in temperatures ranging from -150°F (-100°C) to 300°F (150°C). This precision machined plastic also has excellent radiation stability, chemical resistance as well as hydrolysis resistance for continuous use in hot water and steam.

In many applications, PSU is used over stainless steel parts or aluminum as the material is seven times lighter than stainless steel and can also be steam-cleaned in areas like chemical labs. For this reason, it has a wide range of uses in the following industries: aerospace and defense, medical and life sciences as well as specialized industrial applications.

Our latest machining guide discusses what goes into machining PSU and how its considerations differ from other manufacturing options such as metal machining, injection molding, and 3D printing.

How does AIP approach PSU and its machining process? To start, we’ll explain the difference between machining PSU, a thermoplastic, and machining thermosets.

Machining Thermoplastics vs Thermosets

We’ve already said that PSU is a thermoplastic, but what does that mean exactly?

All polymers can more or less be divided into two categories: thermoplastics and thermosets. The main difference between them is how they react to heat. Thermoplastics like PSU, for example, melt in heat, while thermosets remain “set” once they’re formed. Understanding the technical distinction between these types of materials is essential to CNC machining them properly.

The table below outlines the main properties of thermoplastics versus thermosets:

Thermoplastics |

Thermosets |

|

|

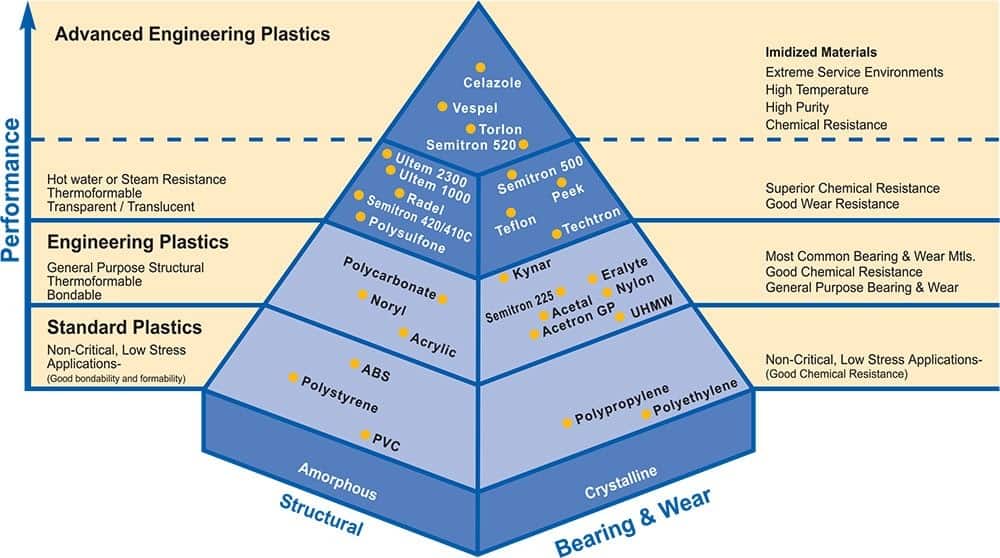

From there, thermoplastics are categorized into amorphous or crystalline polymers per the figure below:

Based off of the chart, PSU is an amorphous, high performance engineering thermoplastic, meaning its molecular structure is randomly formed. The result is that amorphous materials soften gradually with temperature increase, making them easy to thermoform.

Properties of PSU (Polysulfone)

Amorphous thermoplastics are usually translucent in color, but the gradients vary. PSU, for instance, is amber semi-transparent.

Since they are isotropic in flow, they have better dimensional stability than semi-crystalline plastics and are less likely to warp. Thermoplastics like PSU offer superior impact strength and are best used for structural applications.

The materials bond well using adhesives. They also tend to offer excellent resistance to hot water and steam, good chemical resistance, stiffness and strength. PSU and PEI are especially good examples of amorphous thermoplastics offering these qualities.

Machining PSU (Polysulfone)

Annealing PSU

Like many amorphous thermoplastics, PSU is especially sensitive to stress-cracking, so stress-relieving through an annealing process is highly recommended before machining. Annealing PSU greatly reduces the likelihood that surface cracks and internal stresses will occur from the heat generated. Post-machining annealing also helps to reduce stresses that could potentially contribute to premature failure. AIP uses computer controlled annealing ovens for the highest quality precision machining of PSU and other thermoplastics.

Machining PSU

Non-aromatic, water-soluble coolants are most suitable for ideal surface finishes and close tolerances. These include pressurized air and spray mists. Coolants have the additional benefit of extending tool life as well.

Many metal shops use petroleum-based coolants, but these types of fluids attack amorphous thermoplastics like PSU. Many past experiences have shown parts going to customer without cracks, only to develop cracks over time due to exposure to metal machine shop fluids. Be sure to use a facility like AIP who only machines polymers.

Preventing Contamination

Contamination is a serious concern when machining polymer components for technically demanding industries such as aerospace sciences. To ensure the highest level of sanitation down to the sub-molecular level, AIP Precision Machining designs, heat-treats, and machines only plastics with any sub-manufactured metalwork processed outside our facility. This allows us to de-risk the process from metallic cross contamination.

PSU (Polysulfone) Machining Guide Supportive Information

or request a quote here.