Modern aerospace, medical, and defense applications demand polymer components with tolerances as precise as 0.001 inches. Precision CNC machining meets these exacting requirements through advanced multi-axis machining centers and specialized tooling systems. These sophisticated manufacturing processes enable the production of complex geometries while maintaining strict dimensional accuracy across high-performance polymer materials like PEEK and Torlon.

The successful machining of precision plastic parts requires careful consideration of material properties, cutting parameters, and quality control protocols. Leading manufacturers maintain AS9100, ISO 9001, and ISO 13485 certifications to ensure consistent quality across all machined components. This technical overview examines the essential aspects of high-precision plastics machining, including material selection, advanced machining strategies, quality assurance systems, and emerging industry applications.

Key Considerations for CNC Machining High-Performance Plastics

Precision CNC machining of high-performance plastics just needs careful attention to several technical factors. A deep grasp of these essential elements will give optimal results when you produce precision plastic parts for complex applications.

Material selection based on application

Choosing the right plastic materials affects machining outcomes significantly. High-performance plastics like PEEK are perfect for aerospace and medical applications due to their excellent temperature resistance and mechanical strength. A material’s ability to be machined depends on these properties:

| Property | Impact on Machining |

| Thermal stability | Heat resistance during cutting |

| Dimensional stability | Maintaining tolerances |

| Impact strength | Tool pressure resistance |

| Wear resistance | Surface finish quality |

Design considerations for polymer parts

Polymer part design works differently from metal machining and requires attention to specific parameters. The design must account for several key elements:

- Minimum wall thickness (typically 1.5mm for plastics)

- Corner radii to prevent stress concentration

- Appropriate depth-to-width ratios for cavities

- Temperature-compensated tolerances

Tooling and fixture requirements

Machining precision plastics requires specialized tools and fixtures. Tool selection depends on how plastics behave, especially their heat sensitivity and chip formation patterns. Most thermoplastics work well with high-speed steel (HSS) tools. Reinforced materials need carbide tooling to deliver the best results.

The right fixtures are vital to achieve dimensional accuracy. Modular fixtures adapt easily to parts of all shapes, and vacuum fixtures stop workpieces from warping during machining. Clamping forces must be balanced carefully as well – too much force distorts the material while too little makes the workpiece unstable.

Manufacturers should follow specific cutting guidelines to get optimal results. Feed rates usually fall between 0.005 and 0.015 IPR, based on material type and cutting method. Careful control of spindle speeds prevents excess heat that could affect both dimensional stability and surface quality.

Advanced CNC Machining Strategies

Plastic component production just needs sophisticated machining strategies to achieve better precision and efficiency. Modern CNC technology uses three distinct approaches that revolutionize plastic parts manufacturing.

High-speed machining techniques

High-speed machining (HSM) has transformed plastic component production with its rapid, light-pressure cuts. This advanced method brings several important benefits:

- Shorter cycle times and longer tool life

- Minimal heat transfer during operations

- Better surface finish quality

- Higher material removal rates

The technique follows specialized trochoidal machining paths that maintain constant feed rates and optimize material removal. These systems run at speeds between 10,000-40,000 RPM and use direct-drive or electric spindles to achieve maximum precision.

Micro-machining capabilities

Modern micro-machining technology creates intricate plastic components with incredibly small features – just 1 μm in size. These advanced CNC systems come with several key features:

| Feature | Capability |

| Tool Control | Micrometer-level precision |

| Surface Finish | Ultra-smooth completion |

| Feature Size | Down to 1 μm tolerance |

| Material Range | Various high-performance plastics |

The system uses CAD/CAM software to transform complex 3D models into precise tool paths that ensure consistent results in every production run.

5-axis simultaneous machining

5-axis simultaneous machining stands at the forefront of precision plastic manufacturing. This advanced method controls tool movement along five different axes: X, Y, Z, plus A-axis (tilt) and B-axis (rotation). The technology delivers several key benefits:

Complex contour surfaces need minimal setup, multiple faces can be processed in one operation, and tool angles optimize surface finishes while smart path planning cuts down machining time.

The system keeps cutting tools in perfect position relative to work surfaces. This improves material removal rates substantially while maintaining tight tolerances. Medical device and aerospace components need complex geometries with precise specifications, and that’s where this advanced capability becomes especially valuable.

Ensuring Quality and Precision

Quality control is critical for any successful precision CNC machining project. The processes and people within operations must ensure consistent production of high-performance plastic components. Superior results emerge in all production phases when manufacturing facilities implement detailed quality assurance protocols.

In-process monitoring systems

CNC monitoring solutions use advanced data collection and analysis tools to maintain precise manufacturing standards. These systems provide:

- Live production data visualization

- Automated fault detection and classification

- Tool condition monitoring and wear analysis

- Statistical process control (SPC) implementation

Machine monitoring interfaces track critical parameters such as power inputs, spindle speeds, and tool positions that allow quick corrective actions during deviations.

Post-machining treatments

Post-processing operations are a vital part of getting the best component performance. Controlled annealing processes relieve stress and help maintain dimensional stability. This becomes especially important when you have parts that need specific treatments.

| Treatment Type | Primary Benefits |

| Annealing | Reduces internal stress |

| Cryogenic Deburring | Precise edge finishing |

| Heat Treatment | Better clarity for optical components |

| Chemical Finishing | Improved surface characteristics |

Components that need extreme precision or operate in demanding environments depend heavily on these treatments.

Dimensional accuracy and surface finish optimization

Superior surface finish quality depends on several factors that affect machining accuracy. Precision control measures play a vital role:

- High-precision machine tools with advanced calibration systems

- Systematic tool checks and timely replacements

- Controlled room temperature for stable machining conditions

- Live dimensional verification systems

Surface finish optimization uses different techniques including vibratory polishing to bead blasting, based on what each application needs. Quality managers employ live quality tracking systems that monitor reject rates and quickly fix problems whenever they arise.

Manufacturers can consistently achieve tight tolerances of 0.001 inches with sophisticated monitoring systems, targeted post-machining treatments, and precise dimensional control. These methods help maintain excellent surface finish qualities in varying high-performance plastic materials.

Applications and Future Trends

Market projections suggest the precision plastics machining industry will expand from USD 95.00 billion to USD 154.00 billion by 2032, with a compound annual growth rate of 5%.

Industries benefiting from precision plastic machining

Modern advanced machining technologies have transformed manufacturing in many sectors. These capabilities serve essential needs in several major industries:

| Industry | Primary Applications |

| Aerospace | Structural components, lightweight assemblies |

| Medical | Implants, monitoring equipment, surgical tools |

| Defense | Communication systems, protective equipment |

| Electronics | Circuit board housings, precision connectors |

| Oil & Gas | Chemical-resistant seals, valve components |

Emerging materials and their machining challenges

The development of high-performance composites creates new opportunities and challenges for precision machining. Carbon fiber reinforced polymers (CFRP) and superalloy metal matrix composites provide superior strength-to-weight ratios while maintaining excellent thermal and corrosion resistance properties. These materials need specialized approaches:

- Advanced tooling systems with diamond-tipped cutters

- Precise thermal management during machining

- Enhanced fixturing for composite stability

- Specialized post-processing treatments

Advancements in CNC technology for plastics

New technology has altered the map of precision machining. AI and Internet of Things (IoT) capabilities now offer better process control and optimization than ever before. Modern systems come with several smart features.

Smart Manufacturing Features:

- Immediate analytics to optimize processes

- Predictive maintenance protocols

- Automated tool management systems

- Better quality control through sensor integration

The industry’s steadfast dedication to sustainability leads to quicker machining processes. These processes focus on reducing waste and optimizing energy use. Advanced robotics work with CNC systems to automate tool changes and handle materials. This setup substantially boosts production efficiency while keeping precise tolerances at the micron level.

These technological breakthroughs and improved material capabilities have positioned the precision plastics machining industry to grow in a variety of applications. The priority remains clear – to deliver complex components that meet strict quality and performance standards.

Conclusion

Precision CNC machining of high-performance plastics delivers components with tolerances as precise as 0.001 inches. Advanced machining strategies like high-speed processing, micro-machining, and 5-axis simultaneous operations help manufacturers meet rigorous specifications in aerospace, medical, and defense applications. The combination of sophisticated processes, comprehensive quality control systems, and specialized material knowledge ensures consistent production of complex components that meet strict industry standards.

Smart technology integration and improved process control capabilities continue to push manufacturing excellence forward in this specialized field. Multiple sectors show a growing need for high-performance plastic components, indicating substantial market growth potential.

FAQs

What precision can be achieved when machining HDPE?

Our comprehensive HDPE machining and fabrication services can achieve precision tolerances up to +/-0.005 inches.

Which plastics are most suitable for CNC routing?

Polycarbonate and ABS are frequently used for CNC machining. ABS is particularly cost-effective and one of the easiest plastics to machine.

What is the typical timeframe for CNC machining?

The duration for CNC machining can vary: for 1-10 pieces, it typically takes about 3-5 days, while 10-500 pieces might take 7-20 days. Factors such as the complexity and geometry of the part significantly influence the machining time.

What is considered the optimal tolerance level for precision machining?

A tolerance of ± 0.005 inches (0.127 mm) is generally regarded as the standard for precision CNC machining, representing the acceptable range of deviation. However, with advanced equipment and skilled operators, machining tolerances can be tightened to as precise as ± 0.0001 inches.

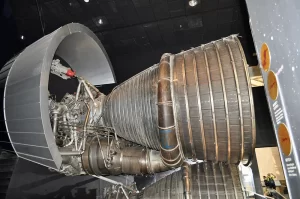

Fuel system components

Fuel system components

In aircraft fuel systems, Delrin®’s

In aircraft fuel systems, Delrin®’s

The selection of materials is crucial in the manufacturing of orthopedic implants, as these materials must offer exceptional biocompatibility, strength, and durability to withstand the rigors of the human body.

The selection of materials is crucial in the manufacturing of orthopedic implants, as these materials must offer exceptional biocompatibility, strength, and durability to withstand the rigors of the human body.

Each of these polymers brings a unique set of properties to the table, making them highly suitable for the demanding requirements of aerospace cryogenic seals. Their combined characteristics of chemical resistance, thermal stability, low moisture absorption, and mechanical durability under extreme conditions position them as optimal materials for aerospace applications, where failure is not an option.

Each of these polymers brings a unique set of properties to the table, making them highly suitable for the demanding requirements of aerospace cryogenic seals. Their combined characteristics of chemical resistance, thermal stability, low moisture absorption, and mechanical durability under extreme conditions position them as optimal materials for aerospace applications, where failure is not an option.

2.3 Market Opportunities

2.3 Market Opportunities 4. Regional Analysis

4. Regional Analysis In a case study for

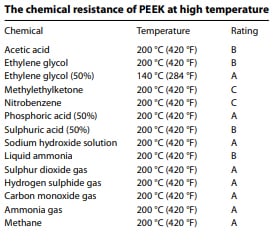

In a case study for  In the medical world, devices often come into contact with a variety of chemicals, be it medications, sterilization agents, or bodily fluids. PEEK is chemically inert, resisting potential degradation or reactions that could compromise the device’s functionality or patient safety. Furthermore, PEEK devices can be sterilized using standard medical sterilization techniques without compromising the material’s integrity.

In the medical world, devices often come into contact with a variety of chemicals, be it medications, sterilization agents, or bodily fluids. PEEK is chemically inert, resisting potential degradation or reactions that could compromise the device’s functionality or patient safety. Furthermore, PEEK devices can be sterilized using standard medical sterilization techniques without compromising the material’s integrity. The chart at the right shows the chemical resistance of PEEK at 200°C (420°F). PEEK exhibits excellent resistance to a wide range of organic and inorganic chemicals. The compatibility of PEEK with many chemicals at 20 °C (68 °F) has been investigated and the results for unreinforced grades are favorable. PEEK is compatible with almost any of the solvents used in HPLC. The only solvent which will attack PEEK are concentrated nitric acid and sulfuric acids.

The chart at the right shows the chemical resistance of PEEK at 200°C (420°F). PEEK exhibits excellent resistance to a wide range of organic and inorganic chemicals. The compatibility of PEEK with many chemicals at 20 °C (68 °F) has been investigated and the results for unreinforced grades are favorable. PEEK is compatible with almost any of the solvents used in HPLC. The only solvent which will attack PEEK are concentrated nitric acid and sulfuric acids.