In the demanding world of subsea operations, components must withstand extreme pressures, corrosive chemicals, and harsh environmental conditions. Precision machining and additive manufacturing have emerged as crucial technologies for producing high-performance polymer components that meet these challenging requirements.

High-performance polymers, particularly PEEK and Carbon PEEK, are revolutionizing subsea applications through their exceptional chemical resistance and mechanical properties. The ARGO 500 HYPERSPEED demonstrates this advancement with its ability to process these super polymers while maintaining mechanical repeatability down to 10 microns. This precision is essential for creating reliable components that can operate in aggressive chemical environments and withstand wide-ranging temperatures and pressures.

This article explores the latest developments in polymer manufacturing for subsea applications, examining how specialized materials and advanced manufacturing processes are addressing critical challenges in the oil and gas industry. From material selection to quality control, readers will gain insights into the technologies and methodologies that ensure the reliability of mission-critical subsea components.

Key Takeaways

| Section | Key Takeaway |

| Introduction | High-performance polymers like PEEK and Carbon PEEK, combined with precision machining and additive manufacturing, address critical challenges in subsea environments such as corrosion, extreme pressure, and temperature. |

| Evolution of Polymer Materials in Subsea Environments | Advanced polymers are replacing metals due to their inherent corrosion resistance, reduced weight, and long-term performance, reducing the need for secondary protection systems. |

| Chemical Resistance Requirements in Corrosive Conditions | Materials like PEEK and PTFE offer superior chemical resistance, but machining and post-processing must preserve these properties to ensure longevity under harsh chemical exposure. |

| Temperature and Pressure Tolerance Advancements | Subsea polymers must perform reliably at >200°C and >140 MPa; modern manufacturing processes and material development are meeting these requirements through simulations and empirical testing. |

| Precision Machining Technology for Critical Polymer Components | Micron-level tolerances are achievable on polymer components through specialized CNC techniques, temperature control, and material-specific tooling—critical for seals and valve seats. |

| Surface Finish Optimization Techniques | Advanced finishing methods ensure sealing integrity, improving functional performance. |

| Additive Manufacturing with High-Temperature Polymers | Roboze’s ARGO 500 enables precise 3D printing of high-performance polymers with controlled chamber environments, offering new design possibilities for complex subsea parts. |

| PEEK and ULTEM™ AM9085F Processing Parameters | PEEK and ULTEM™ require strict thermal conditions for extrusion and chamber environments to maintain structural integrity and ensure repeatability in subsea components. |

| Post-Processing Requirements for Functional Parts | Additively manufactured parts often require mechanical and thermal post-processing (e.g., thermal treatment, vapor smoothing) to achieve target mechanical and sealing properties. |

| Material Selection Criteria for Subsea Applications | Material selection is application-driven, with PEEK-based composites used for pressure resistance and fluoropolymers for chemical stability. |

| Conclusion | The integration of precision machining and additive manufacturing enables high-performance subsea components that meet industry demands for reliability, chemical resistance, and dimensional control. |

Evolution of Polymer Materials in Subsea Environments

Evolution of Polymer Materials in Subsea Environments

Subsea environments present extraordinary challenges for engineering materials, with constant exposure to corrosive saltwater, extreme pressures, and fluctuating temperatures. The evolution of polymer materials for these demanding applications represents a significant technological advancement for offshore industries.

Traditional Materials vs. High-Performance Polymers

For decades, offshore oil and gas infrastructure relied primarily on metals protected by synthetic polymers, with hundreds of thousands of metric tons of plastics used worldwide to shield metallic flowlines and equipment against seawater corrosion. However, this approach has shifted dramatically with the emergence of high-performance polymers as structural materials themselves.

Traditional metal components face significant limitations in subsea applications, most notably their susceptibility to corrosion. Research indicates that more than half (51%) of all failures in traditional oil and gas pipelines occur due to internal corrosion. In contrast, engineered polymers offer inherent corrosion resistance, substantial weight reduction, and improved service life.

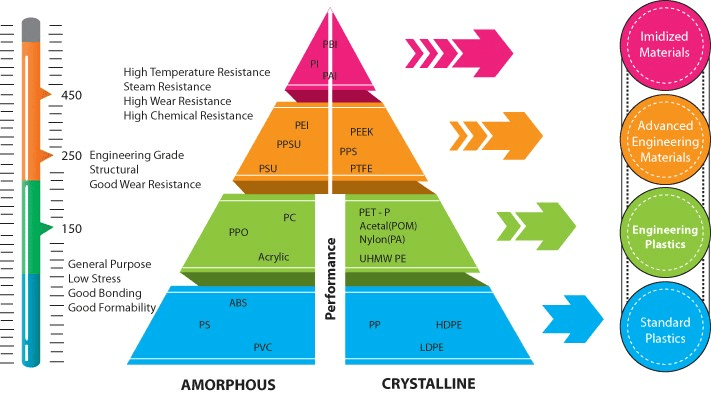

The weight advantage of polymers is substantial—engineering and high-temperature grade plastics such as PEEK, PEI, POM, and nylon weigh approximately 50% less than aluminum, while some composite materials weigh about 25% as much as steel. This weight reduction delivers significant benefits:

- Improved buoyancy in underwater operations

- Reduced need for costly buoyancy materials

- Lower installation and handling costs

- Enhanced maneuverability of subsea equipment

Furthermore, unlike traditional materials that rapidly corrode in marine environments, polymer components maintain their integrity over extended periods, ensuring long-term functionality without the need for cathodic protection.

Chemical Resistance Requirements in Corrosive Conditions

As the offshore industry pursues deeper wells, exposure to increasingly aggressive chemical environments has accelerated the need for chemically resistant polymers. Modern subsea operations encounter extremes of operating temperature and pressure—up to 315°C and 3,000 bars—often combined with corrosive elements like hydrogen sulfide (H₂S) and carbon dioxide (CO₂).

High-performance materials demonstrate exceptional resistance to these corrosive elements. PEEK (Polyetheretherketone) and PTFE (Polytetrafluoroethylene) are leading solutions for critical subsea components due to their superior chemical stability. Nevertheless, even these advanced materials show limitations. Studies reveal that PEEK, though widely believed to be stable in seawater, undergoes both physical and chemical changes during prolonged exposure, resulting in reduced bending modulus and lowered glass transition temperature.

Advanced polymer manufacturing processes, including precision machining and additive manufacturing, have enhanced material performance in these harsh environments. AIP Precision Machining specializes in producing components with tolerances as low as 0.002mm that maintain their chemical resistance properties even after extensive machining operations, preserving the integral material structure that provides corrosion protection.

Temperature and Pressure Tolerance Advancements

The temperature and pressure tolerance of subsea polymers has advanced significantly, responding to industry demands for materials capable of functioning at greater depths. Whereas average downhole operations typically reached temperatures of 150°C and pressures of 70-100 MPa, current industry challenges involve accessing wells with conditions exceeding 200°C and 140 MPa, with limiting targets around 250°C and 170 MPa.

Molecular dynamics simulations have provided valuable insights into polymer behavior under these extreme conditions. Research shows that environmental exposure significantly affects the glass transition temperature (Tg) of polymers, with epoxy being more sensitive than vinyl ester.

Additive manufacturing technologies, such as Roboze’s ARGO 500 HYPERSPEED, have revolutionized the production of high-temperature polymer components. This system processes materials like PEEK and ULTEM™ with exceptional dimensional accuracy, creating parts that maintain their mechanical properties under extreme subsea conditions. These manufacturing capabilities enable the production of complex valve components, seals, and seats that would be difficult or impossible to create through traditional methods.

The continuous evolution of polymer materials for subsea environments has not only addressed corrosion challenges but has also enhanced overall system performance, reduced maintenance requirements, and extended operational lifespans in some of the most demanding environments on earth.

Precision Machining Technology for Critical Polymer Components

Manufacturing critical polymer components for subsea applications requires exceptional precision and specialized machining technologies to ensure reliability in extreme operating conditions. Modern CNC machining capabilities, coupled with additive manufacturing processes, have reshaped how high-performance polymers are processed for demanding subsea environments.

CNC Machining Capabilities for Complex Geometries

Precision CNC machining of high-performance polymers enables the production of intricate subsea components with complex geometries that would be otherwise unattainable through conventional manufacturing methods. Advanced 5-axis machining centers provide the versatility needed to access every surface of a component in a single setup, consequently minimizing human intervention and reducing potential errors in the production process.

For subsea valve components specifically, multi-axis machining delivers several critical advantages:

- The ability to produce complex contoured surfaces with minimal setup changes

- Processing of multiple faces in a single operation

- Optimization of tool angles for enhanced surface finishes

Modern polymer machining systems operate at speeds between 10,000-40,000 RPM using direct-drive or electric spindles to maximize precision. These advanced systems employ specialized trochoidal machining paths that maintain constant feed rates, ultimately optimizing material removal while minimizing heat buildup that could compromise the dimensional stability of temperature-sensitive polymers.

Achieving Micron-Level Tolerances for Valve Components

The successful machining of high-precision polymer valve seats and seals requires meticulous attention to several technical factors. First, tool selection must account for the thermal properties of the specific polymer being machined. While high-speed steel (HSS) tools work well for most thermoplastics, reinforced materials like carbon-filled PEEK demand carbide tooling to maintain dimensional accuracy.

Temperature management represents a critical aspect of achieving micron-level tolerances in subsea valve components. Because PTFE and other fluoropolymers can experience dimensional changes of up to 3% between 0°C and 100°C, sophisticated temperature-controlled manufacturing environments are essential. Additionally, real-time monitoring systems that track spindle speeds, power inputs, and tool positions enable immediate corrective actions during production.

For subsea applications where sealing is paramount, even a micrometer variation can mean the difference between a watertight seal and gradual failure. Therefore, quality procedures including first-off inspections and batch checking at agreed quantities ensure that any tool wear or process fluctuations remain within acceptable limits.

Surface Finish Optimization Techniques

Surface finish quality directly impacts the functionality of subsea polymer components, especially in valve seats and seals where imperfections can compromise sealing integrity. Standard CNC machining of polymers produces a surface roughness of 3.2μm, although finishes as smooth as 0.4μm are attainable with specialized processes.

The combined capabilities of precision machining and additive manufacturing represent a paradigm shift in producing mission-critical subsea components. Modern hybrid approaches that integrate both technologies leverage the complex geometry capabilities of additive manufacturing with the superior surface finish and tight tolerances of precision machining. This synergy is particularly valuable for prototype development and small-batch production of specialized valve components, where traditional tooling would be prohibitively expensive or time-consuming.

Additive Manufacturing with High-Temperature Polymers

The integration of high-temperature polymers with additive manufacturing technology has expanded the possibilities for producing complex subsea components that withstand extreme conditions. This approach offers unique advantages for valve seats, seals, and pressure-bearing components where customization and material performance are paramount.

ARGO 500 HYPERSPEED: Technical Capabilities

The ARGO 500 HYPERSPEED represents a significant advancement in high-temperature polymer processing. This system features a large 500x500x500mm build volume with extrusion temperatures reaching 500°C (932°F), enabling processing of the most demanding high-performance polymers. Its heated chamber achieves temperatures up to 180°C (356°F) in just over an hour, essential for reducing thermal shock and controlling cooling rates to minimize residual stresses in printed parts.

The machine utilizes a dual extruder system with 0.4mm and 0.6mm nozzle options, providing flexibility for both detail work and faster production. At its core, four integrated high-temperature material dryers operating at 120°C (248°F) protect hygroscopic polymers from moisture degradation—a critical factor when processing engineering-grade materials for subsea applications.

PEEK and ULTEM™ AM9085F Processing Parameters

PEEK (Polyetheretherketone) and ULTEM™ AM9085F (Polyetherimide) stand out for subsea applications due to their exceptional thermal and chemical properties. ULTEM™ AM9085F demonstrates a Heat Deflection Temperature (HDT) of 175°C (347°F), with inherent flame retardancy and minimal smoke generation—achieving UL 94-V0 certification without additives.

For optimal printing results, ULTEM™ AM9085F requires chamber temperatures of at least 170°C, while PEEK processing demands even higher temperatures—typically 360-450°C for extrusion and a minimum bed temperature of 120°C. Both materials benefit from vacuum build plates that ensure adhesion during printing and maintain critical dimensional stability.

Post-Processing Requirements for Functional Parts

Functional subsea components manufactured via additive processes typically require post-processing to achieve final specifications. Most high-performance printed polymers benefit from thermal post-processing—a controlled heat treatment that enhances crystallinity, improves interlayer bonding, and ultimately increases mechanical strength to over 90% of the original material properties.

Advanced coating processes further expand functionality, with options for metallic coatings via electroplating or physical vapor deposition to enhance wear resistance. For parts requiring maximum chemical protection, specialized polymer coatings can be applied to improve environmental resistance without compromising the base material’s mechanical properties.

Material Selection Criteria for Subsea Applications

Selecting the right material for subsea applications remains critical for component longevity, as improper choices can lead to premature failure, environmental contamination, and costly downtime. AIP Precision Machining employs specialized manufacturing approaches to meet the stringent requirements of extreme subsea environments.

PEEK-Based Composites for Valve Seats and Seals

PEEK (Polyetheretherketone) dominates subsea valve seat and seal applications thanks to its exceptional mechanical stability under pressure. When machined or additively manufactured with precision tolerances, PEEK components maintain their dimensional integrity even after prolonged exposure to seawater at elevated temperatures. For enhanced performance, carbon-fiber reinforced grades offer:

- Increased stiffness with minimal creep under high loads

- Superior abrasion resistance for dynamic sealing surfaces

- Enhanced thermal conductivity reducing thermal expansion issues

- Exceptional resistance to hydrogen sulfide present in pre-salt oil fields

Fluoropolymer Solutions for Chemical Exposure

For extreme chemical resistance, fluoropolymers offer superior performance compared to other polymer families. Specialized PTFE compounds with aromatic polymer fillers are applicable for high-integrity valve stem sealing. These materials create exceptionally smooth dynamic sealing surfaces after a short run-in period, making them ideal for low-viscosity fluids and gasses.

Alternatively, FEP and PFA fluoropolymers provide excellent thermal stability alongside chemical resistance, with heat shrink sleeving options available from 10mm to 400mm diameters for protecting critical subsea components.

Conclusion

Advanced polymer manufacturing has transformed subsea component production through precision machining and additive manufacturing technologies. These manufacturing methods, particularly when applied to PEEK and fluoropolymer materials, deliver exceptional chemical resistance and mechanical stability under extreme pressures and temperatures.

AIP Precision Machining achieves micron-level tolerances through specialized CNC processes, while Roboze’s ARGO 500 HYPERSPEED system processes high-temperature polymers with remarkable precision. Together, these complementary technologies create reliable valve seats, seals, and critical components that maintain their integrity in aggressive chemical environments.

Quality control systems and rigorous material testing protocols ensure component reliability throughout their service life. This comprehensive approach combines material science advances with manufacturing precision to address the oil and gas industry’s most demanding requirements.

FAQs

Q1. What are the main advantages of using high-performance polymers in subsea applications?

High-performance polymers offer inherent corrosion resistance, significant weight reduction, and improved service life compared to traditional metal components. They maintain their integrity in harsh marine environments without needing cathodic protection.

Q2. How do precision machining technologies contribute to the production of critical subsea components?

Precision machining technologies, such as advanced 5-axis CNC machining, enable the production of complex geometries with micron-level tolerances. This precision is crucial for creating reliable valve seats, seals, and other components that can withstand extreme pressures and corrosive environments.

Q3. What role does additive manufacturing play in producing subsea polymer components?

Additive manufacturing, especially with systems like the ARGO 500 HYPERSPEED, allows for the production of complex parts using high-temperature polymers like PEEK and ULTEM™. This technology enables the creation of customized components with intricate designs that would be difficult or impossible to produce through traditional methods.

Q4. What quality control measures are essential for ensuring the reliability of subsea polymer components?

Quality control for subsea polymer components involves dimensional verification methods, non-destructive testing, comprehensive documentation and traceability systems, and performance validation in simulated environments. These measures ensure that components meet strict industry standards and can perform reliably under extreme conditions.

In the aerospace parts manufacturing sector, the selection and processing of materials are driven by the industry’s unyielding pursuit of advancements in strength, weight reduction, and resistance to extreme conditions.

In the aerospace parts manufacturing sector, the selection and processing of materials are driven by the industry’s unyielding pursuit of advancements in strength, weight reduction, and resistance to extreme conditions.

Each of these polymers brings a unique set of properties to the table, making them highly suitable for the demanding requirements of aerospace cryogenic seals. Their combined characteristics of chemical resistance, thermal stability, low moisture absorption, and mechanical durability under extreme conditions position them as optimal materials for aerospace applications, where failure is not an option.

Each of these polymers brings a unique set of properties to the table, making them highly suitable for the demanding requirements of aerospace cryogenic seals. Their combined characteristics of chemical resistance, thermal stability, low moisture absorption, and mechanical durability under extreme conditions position them as optimal materials for aerospace applications, where failure is not an option.

2.3 Market Opportunities

2.3 Market Opportunities 4. Regional Analysis

4. Regional Analysis In a case study for

In a case study for  In the medical world, devices often come into contact with a variety of chemicals, be it medications, sterilization agents, or bodily fluids. PEEK is chemically inert, resisting potential degradation or reactions that could compromise the device’s functionality or patient safety. Furthermore, PEEK devices can be sterilized using standard medical sterilization techniques without compromising the material’s integrity.

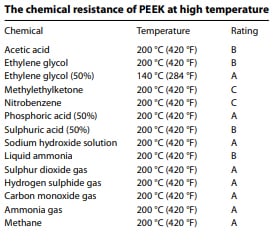

In the medical world, devices often come into contact with a variety of chemicals, be it medications, sterilization agents, or bodily fluids. PEEK is chemically inert, resisting potential degradation or reactions that could compromise the device’s functionality or patient safety. Furthermore, PEEK devices can be sterilized using standard medical sterilization techniques without compromising the material’s integrity. The chart at the right shows the chemical resistance of PEEK at 200°C (420°F). PEEK exhibits excellent resistance to a wide range of organic and inorganic chemicals. The compatibility of PEEK with many chemicals at 20 °C (68 °F) has been investigated and the results for unreinforced grades are favorable. PEEK is compatible with almost any of the solvents used in HPLC. The only solvent which will attack PEEK are concentrated nitric acid and sulfuric acids.

The chart at the right shows the chemical resistance of PEEK at 200°C (420°F). PEEK exhibits excellent resistance to a wide range of organic and inorganic chemicals. The compatibility of PEEK with many chemicals at 20 °C (68 °F) has been investigated and the results for unreinforced grades are favorable. PEEK is compatible with almost any of the solvents used in HPLC. The only solvent which will attack PEEK are concentrated nitric acid and sulfuric acids.

One of the primary growth drivers for the aerospace parts manufacturing industry is the increasing demand for aircraft maintenance and replacement. As commercial airlines, military aircraft, and general aviation operations continue to expand, the need for high-quality, reliable aircraft components escalates. Furthermore, with aircraft often exposed to harsh environmental conditions, the need for regular maintenance and part replacement is paramount, ensuring operational safety and efficiency.

One of the primary growth drivers for the aerospace parts manufacturing industry is the increasing demand for aircraft maintenance and replacement. As commercial airlines, military aircraft, and general aviation operations continue to expand, the need for high-quality, reliable aircraft components escalates. Furthermore, with aircraft often exposed to harsh environmental conditions, the need for regular maintenance and part replacement is paramount, ensuring operational safety and efficiency.

Predictive maintenance, powered by big data and analytics, is transforming the aviation industry. By leveraging flight-recorded data, airlines can significantly reduce maintenance expenditures and enhance operational efficiency. This trend is creating unique growth opportunities for aerospace parts manufacturers, enabling them to meet evolving industry requirements.

Predictive maintenance, powered by big data and analytics, is transforming the aviation industry. By leveraging flight-recorded data, airlines can significantly reduce maintenance expenditures and enhance operational efficiency. This trend is creating unique growth opportunities for aerospace parts manufacturers, enabling them to meet evolving industry requirements.

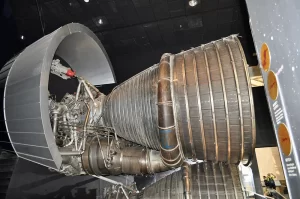

The temperature adaptability of these plastics is demonstrated by their operational reliability within the space environment, where temperatures range from -150°C to 130°C, and they exhibit resistance to elevated temperatures in rocket engine applications. Exhibiting optimal flammability characteristics, these materials are compatible with both liquid oxygen (LOX) and gaseous oxygen (GOX), critical for maintaining safety in the highly reactive environments of spacecraft.

The temperature adaptability of these plastics is demonstrated by their operational reliability within the space environment, where temperatures range from -150°C to 130°C, and they exhibit resistance to elevated temperatures in rocket engine applications. Exhibiting optimal flammability characteristics, these materials are compatible with both liquid oxygen (LOX) and gaseous oxygen (GOX), critical for maintaining safety in the highly reactive environments of spacecraft.

Ultem’s notable characteristics are high processability, dimensional stability, environmental stress resistance, and flammability resistance, all of which are critical for the harsh and unpredictable conditions of space. It also offers long-term heat resistance, which is a significant factor for components exposed to extreme temperatures, which is beneficial for rocket launches.

Ultem’s notable characteristics are high processability, dimensional stability, environmental stress resistance, and flammability resistance, all of which are critical for the harsh and unpredictable conditions of space. It also offers long-term heat resistance, which is a significant factor for components exposed to extreme temperatures, which is beneficial for rocket launches. Torlon also offers excellent wear and radiation resistance, both of which are essential properties for materials used in space environments. Inherent low flammability and smoke emission make it an ideal material for high temperature and potentially hazardous conditions present in rocket propulsion systems.

Torlon also offers excellent wear and radiation resistance, both of which are essential properties for materials used in space environments. Inherent low flammability and smoke emission make it an ideal material for high temperature and potentially hazardous conditions present in rocket propulsion systems. One of the remarkable characteristics of Vespel is its high-temperature resistance. This makes it ideal for use in the space industry where materials are frequently subjected to extreme temperatures. Furthermore, Vespel does not exhibit significant outgassing, even at high temperatures. This makes it useful for manufacturing lightweight heat shields and crucible support structures for spacecraft and rocket propulsion systems, where any outgassing could cause contamination and performance issues.

One of the remarkable characteristics of Vespel is its high-temperature resistance. This makes it ideal for use in the space industry where materials are frequently subjected to extreme temperatures. Furthermore, Vespel does not exhibit significant outgassing, even at high temperatures. This makes it useful for manufacturing lightweight heat shields and crucible support structures for spacecraft and rocket propulsion systems, where any outgassing could cause contamination and performance issues.

Since then, PEEK has only expanded as a performance biomaterial for instrumented spine surgery. In the United States, spine fusion is one of the leading surgeries for patients who suffer from chronic neck and back pain that does not respond to preliminary treatments.

Since then, PEEK has only expanded as a performance biomaterial for instrumented spine surgery. In the United States, spine fusion is one of the leading surgeries for patients who suffer from chronic neck and back pain that does not respond to preliminary treatments. The fields of orthopedics and spinal fusion continue to research new methods for best practices in the industry. Over the last three decades, medical-grade PEEK has established itself as the performance biomaterial of choice for surgeons and OEMs. Medical device design demands the highest level of sanitation, biocompatibility, and precision in one of the most extreme environments, the human body.

The fields of orthopedics and spinal fusion continue to research new methods for best practices in the industry. Over the last three decades, medical-grade PEEK has established itself as the performance biomaterial of choice for surgeons and OEMs. Medical device design demands the highest level of sanitation, biocompatibility, and precision in one of the most extreme environments, the human body.

Besides incredible thermal stability and resistance rivaling aluminum, copper, and steel, Torlon® is well known for its strength under pressure and chemical resistance. Torlon’s benefits include the following:

Besides incredible thermal stability and resistance rivaling aluminum, copper, and steel, Torlon® is well known for its strength under pressure and chemical resistance. Torlon’s benefits include the following: