In the aerospace engineering market, precision parts manufacturing is a critical discipline that significantly influences the functionality and safety of aviation technologies.

From the early 20th century’s rudimentary constructions to today’s advanced aerospace assemblies, the sector has seen a pivotal shift towards the utilization of high-performance materials and complex manufacturing techniques.

This evolution is set to propel the industry from a valuation of $910 billion in 2023 to an estimated $1.297 trillion by 2033, driven by both burgeoning aircraft production and the perpetual need for meticulously crafted replacement components.

Contemporary aerospace manufacturing is defined by stringent precision requirements, with materials selected for their superior strength-to-weight ratios essential in components demanding both lightness and durability.

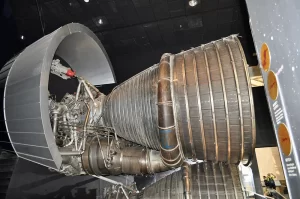

Advanced manufacturing processes including Computer Numerical Control (CNC) machining, flow forming, and rotary forging are employed to ensure components conform to exacting aerospace standards.

The integration of polymer composites and advanced materials such as carbon-fiber-reinforced polymers (CFRP) is instrumental in reducing aircraft mass while sustaining structural robustness. This adoption of innovative materials and precision-focused manufacturing techniques underlines the industry’s commitment to advancing aviation technology through rigorous engineering practices.

This enhanced focus on precision and technological sophistication underscores the modern aerospace manufacturing landscape, emphasizing the industry’s dedication to pushing the boundaries of aviation through precision engineering and state-of-the-art material science.

Advanced Materials and Manufacturing Processes

In the aerospace parts manufacturing sector, the selection and processing of materials are driven by the industry’s unyielding pursuit of advancements in strength, weight reduction, and resistance to extreme conditions.

In the aerospace parts manufacturing sector, the selection and processing of materials are driven by the industry’s unyielding pursuit of advancements in strength, weight reduction, and resistance to extreme conditions.

- Aerospace-grade aluminum and titanium are valued for their exceptional strength-to-weight ratios, vital for components requiring both light weight and durability.

- Aluminum is preferred for its combination of lightness, strength, corrosion resistance, and abundance, making it a cornerstone in aerospace manufacturing.

- Titanium and its alloys, known for their superior strength-to-weight ratio and performance in extreme environments, are extensively utilized in critical aerospace applications.

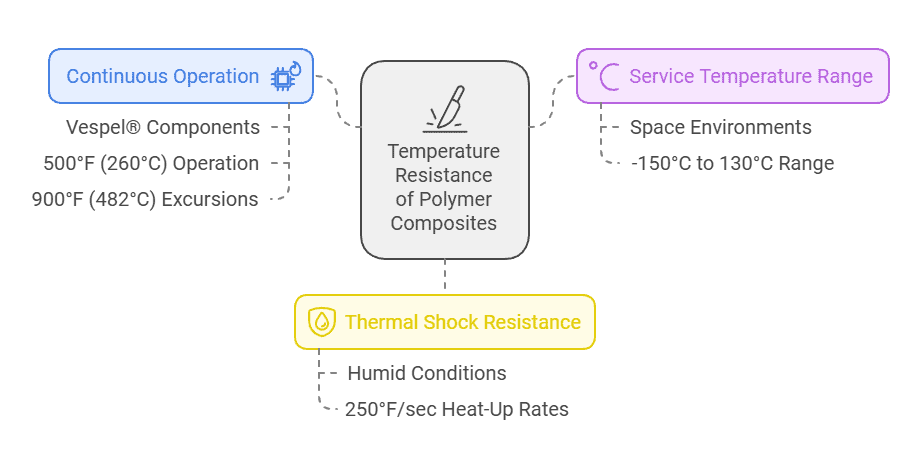

Polymer Composites and Advanced Materials:

- Polymer composites, including carbon-fiber-reinforced-polymers (CFRP), offer a blend of lightweight characteristics and structural integrity, crucial for reducing aircraft and spacecraft weight while maintaining performance.

- Graphene, a novel carbon-based material, is under exploration for its potential in creating high-capacity, lightweight batteries, embodying the aerospace industry’s forward-looking approach to materials innovation.

- Techniques such as powder bed fusion and direct energy deposition stand at the forefront of material processing, ensuring components meet the aerospace industry’s stringent standards.

- The development of machinable alloys and advanced structural technologies like flow forming and rotary forging exemplifies the industry’s commitment to efficiency and precision in manufacturing processes.

Advanced Composites in Aerospace

Advanced composites, characterized by their hybrid nature, combine two or more distinct materials to enhance overall properties, making them indispensable in modern aerospace parts manufacturing. One prominent example is Carbon Fiber Reinforced Polymer (CFRP), widely utilized for its exceptional strength-to-weight ratio, durability, and resistance to corrosion.

Notably, Boeing, a leader in aerospace innovation, has filed a significant number of patents related to CFRP, underscoring its commitment to advancing composite technology.

These materials are pivotal in the production of critical aircraft components such as fuselages, wings, and tail sections. Their application results in substantial weight reduction, which in turn contributes to enhanced fuel efficiency—a key advantage seen in models like Boeing’s 787 Dreamliner, which boasts a 20% improvement in fuel economy over its predecessors.

However, the high cost of production, driven by labor-intensive processes and the need for specialized equipment, has historically limited their widespread adoption.

Despite these challenges, ongoing advancements in precision manufacturing techniques are enhancing the utility and application of these materials.

AIP Precision Machining stands at the forefront, innovating strategies that ensure the highest quality and precision standards while extending the use of advanced composites in aerospace and related industries.

These efforts not only optimize the functionality of advanced composites but also secure their essential role in the evolution of aerospace engineering, meeting the industry’s stringent demands for accuracy and reliability.

Smart Materials: Shaping the Future of Aerospace

The utilization of smart materials is transforming aerospace parts manufacturing by enabling aircraft components to intelligently adapt and respond to dynamic environmental conditions. Shape Memory Alloys (SMAs) and Piezoelectric Materials are at the forefront of this revolution, significantly boosting the performance and operational efficiency of aerospace systems.

Precision in the application of these materials is critical, as the slightest deviations can impact the functionality and safety of the aerospace components.

AIP Precision Machining is uniquely equipped to meet these challenges. With cutting-edge technology and extensive expertise in precision engineering, AIP ensures that the transformative potential of smart materials is fully realized in aerospace applications, setting new standards in performance and reliability.

Shape Memory Alloys and Piezoelectric Materials

- Shape Memory Alloys (SMAs): SMAs are utilized in critical aerospace applications such as wing flaps and landing gear. They contribute significantly to aerodynamics and fuel efficiency by reverting to a pre-determined shape in response to temperature changes.

- Piezoelectric Materials: These materials are essential in the development of sensors and actuators for aircraft. By generating an electric charge in response to mechanical stress, they help monitor and control the structural health of the aircraft, particularly in the wings and fuselage.

Innovations in Morphing Wings and Self-Healing Materials

- Morphing Wings: Smart materials facilitate the development of morphing wings, which adjust their shape during flight to optimize performance. This adaptability is crucial for reducing drag and improving fuel efficiency.

- Self-Healing Materials: Capable of autonomously repairing minor damages and cracks, these materials extend the lifespan of aerospace components, thereby reducing maintenance costs and enhancing safety.

Advanced Sensing and Thermal Control

Smart materials are integral to the development of sophisticated sensing and monitoring systems that detect environmental changes such as temperature and stress, essential for real-time aerospace decision-making.

Additionally, materials with adaptive thermal control properties play a crucial role in managing heat distribution, protecting critical components, and ensuring the optimal performance of onboard electronic systems. The deployment of these advanced materials in aerospace manufacturing not only requires high precision but also compliance with rigorous industry standards such as AS 9100 certification.

This standard is critical as it ensures quality assurance and reliability in all aspects of aerospace manufacturing, from material selection to final product testing. AIP Precision Machining, with its AS 9100 certification, exemplifies adherence to these high standards, guaranteeing that every component manufactured meets the strict requirements for aerospace applications. This commitment to certified quality enhances the potential of smart materials to advance aerospace technology, focusing on sustainability and operational efficiency.

The Impact of Nanocomposites

Nanocomposites are emerging as a transformative force in aerospace parts manufacturing, blending nanoparticles with traditional composite materials to achieve superior properties. These materials are engineered by incorporating nanoscale fillers into resins or polymers, resulting in composites that are lightweight yet extremely strong and durable. The integration of nanotechnology within composites leads to enhancements in mechanical strength, thermal stability, and electrical conductivity, which are critical for aerospace applications where performance and reliability are paramount.

Enhanced Mechanical Properties

Nanocomposites significantly improve the mechanical properties of aerospace materials, including tensile strength, stiffness, and impact resistance.

For instance, the addition of nano-sized carbon fibers or silica particles to polymer matrices has shown to increase the load-bearing capacity of aircraft components while maintaining a low weight. This enhancement is crucial in the design of more efficient and higher-performing aircraft structures that can withstand the demanding conditions of aerospace environments.

Thermal and Electrical Conductivity Improvements

By integrating nanomaterials like graphene or metal oxides, nanocomposites gain improved thermal and electrical conductivities. This is particularly advantageous for aerospace parts that require efficient heat dissipation or electrical grounding.

Enhanced thermal stability ensures that components can perform reliably under the extreme temperature variations experienced during flight and re-entry phases, while improved electrical properties are essential for protecting sensitive electronic equipment from static and electromagnetic interference.

These advancements in nanocomposite technology not only drive the performance and efficiency of aerospace systems but also contribute to the overall safety and longevity of aircraft. The strategic incorporation of nanotechnology in composite materials is setting new benchmarks in aerospace engineering, aligning with the industry’s goals of innovation and sustainability.

The Promise of Additive Manufacturing

Additive manufacturing, often synonymous with 3D printing, is transforming aerospace parts manufacturing by enabling the creation of complex, lightweight designs that traditional methods cannot achieve. This innovative approach allows for the production of parts with intricate geometries such as lattice structures and conformal cooling channels, which significantly enhance the performance and efficiency of aerospace components.

Additive Manufacturing (3D Printing) in Aerospace

In the aerospace parts manufacturing sector, additive manufacturing (AM), or 3D printing, has emerged as a revolutionary technology, offering unprecedented flexibility and efficiency. The adoption of AM across various applications illustrates its transformative impact:

Innovative Applications and Prototyping:

- Nano Dimension utilizes AME and DragonFly IV technology for aerospace and defense, showcasing advanced 3D printing capabilities.

- Masten Space Systems leverage 3D printing for rapid prototyping of functional rocket components, including complex parts like the 25,000-pound thrust broadsword engine.

- Lufthansa Technik demonstrate the cost and time efficiency of 3D printing in aerospace tooling and part production, such as the extrusion nozzle for self-luminous escape route markings.

Enhanced Manufacturing Efficiency:

- The Integrated Manufacturing Group at AMRC illustrates time savings in high-tolerance drilling and machining through 3D printed masking jigs.

- NASA and educational institutions like the United States Naval Academy employ 3D printing for space testing and educational purposes, respectively, highlighting the technology’s broad applicability and potential for innovation.

Design and Material Innovations:

- Aerospace companies are increasingly favoring 3D printing for its ability to produce and evaluate multiple design variations quickly, including the production of high-pressure turbine discs from challenging materials like nickel-based superalloys.

- The technology enables the reduction of aircraft mass by experimenting with lightweight, high-strength materials and consolidating multiple parts into a single, more efficient component.

These examples underscore the pivotal role of additive manufacturing in propelling the aerospace parts manufacturing industry forward, driven by its capacity for innovation, efficiency, and material optimization.

The Role of Digital Twin Technology

In the aerospace parts manufacturing arena, digital twin technology has become an indispensible tool, enhancing the precision and reliability of complex systems. This technology offers a comprehensive virtual representation of physical components, including aircraft and satellites, allowing for meticulous testing and validation in simulated environments.

Key aspects include:

- Functionality Across Environments: Digital twins ensure the reliable operation of electronic systems, critical in varying operational conditions.

- Prototyping and Deployment: By mimicking both hardware and software functionalities, digital twins facilitate early modeling and analysis, significantly reducing costs and accelerating deployment rates.

- Real-World Testing: Essential for aerospace and government sectors, this technology enables rigorous testing, validation, and verification processes, enhancing hardware and software compatibility in actual conditions.

Moreover, digital twin technology stands at the forefront of Industry 4.0, integrating data analytics and machine learning to create dynamic, evolving models.

Notable applications include:

- Rolls-Royce’s UltraFan Engine: Utilizing digital twins for creating precise virtual replicas, enabling virtual testing as if the engine were operating in real-world conditions.

- Operational Performance Optimization: Through advanced diagnostics and comprehensive lifecycle management, digital twins offer unparalleled forecasting capabilities, leading to optimized fleet management and superior overall operational efficiency.

This integration of digital twin technology within aerospace manufacturing underscores a significant shift towards smarter, more efficient production methodologies. By harnessing the power of virtual simulations, aerospace engineers can predict maintenance needs, improve equipment development, and streamline the validation of complex systems, marking a pivotal advancement in aerospace parts manufacturing.

Future Trends in Aerospace Parts Manufacturing

Several key trends are poised to redefine the aerospace parts manufacturing landscape, driven by technological advancements and the drive for sustainability:

Technological Innovations:

- Autonomous Flight Systems are on the brink of revolutionizing air travel, with single-pilot commercial aircraft and the potential for pilotless passenger flights, enhancing efficiency and safety.

- Artificial Intelligence (AI) and the Internet of Things (IoT) are streamlining operations from material analysis to predictive maintenance, ensuring a smarter, more responsive supply chain.

- Additive Manufacturing continues to advance, with GE Additive leading in Direct Metal Laser Melting (DMLM) and Electron Beam Melting (EBM) technologies, enabling the production of complex aerospace components with unprecedented precision.

Sustainability and Efficiency:

- The industry’s commitment to sustainability is evident in the exploration of alternative fuels and the adoption of electric propulsion systems, aiming to reduce carbon footprints and operational costs.

- Robotics and Automation are increasingly embraced to enhance production efficiency, while sustainable manufacturing practices focus on cleaner production, waste reduction, and recycling.

Market Dynamics:

- With an anticipated growth to $1.51 trillion by 2032, the aerospace parts manufacturing market is buoyed by the demand for fuel-efficient, lighter aircraft and advanced aeronautical equipment.

- Challenges such as supply chain disruptions and material price volatility are being addressed through diversification and digital transformation, ensuring resilience and security.

These trends underscore a future where aerospace parts manufacturing is more efficient, sustainable, and technologically advanced, promising an exciting era of innovation and growth.

In Conclusion

The aerospace parts manufacturing industry is at the forefront of technological advancement, integrating revolutionary materials, precision engineering techniques, and digital innovations.

As the industry advances, it is poised for significant growth, setting new standards in aerospace capabilities and efficiency.

AIP Precision Machining is at the heart of these developments, bolstered by our AS 9100 and ISO 13485:2016 certifications. The AS 9100 certification is crucial, ensuring that our aerospace manufacturing processes and products consistently meet the highest safety and quality standards. This certification is vital for maintaining the rigorous demands of aerospace component precision and reliability, which are vital in the highly regulated aerospace sector.

Additionally, our ISO 13485:2016 certification, while primarily recognized in the medical devices industry, complements our aerospace capabilities by enforcing stringent quality management practices. This dual certification allows us to handle complex aerospace projects that may involve advanced materials and technologies, providing a cross-industry perspective that enhances innovation and meticulous attention to detail.

These certifications affirm AIP Precision Machining’s commitment to excellence and our capability to meet diverse industry requirements, reinforcing our position as a leader in aerospace parts manufacturing. They underscore our ability to deliver components that not only meet but exceed the evolving expectations of the aerospace industry.

We encourage aerospace entities seeking a manufacturing partner that exemplifies integrity, precision, and advanced technological compliance to consider AIP Precision Machining. Let us collaborate to drive the future of aerospace, where cutting-edge technology and rigorous standards propel us towards unparalleled achievements in aviation excellence.

Contact us at:

Phone: +1 386-274-5335

Website: www.aipprecision.com

FAQs

What are the main obstacles faced in the aerospace sector?

The aerospace industry encounters several significant challenges, including:

- Digital Transformation of Manufacturing: While digital transformation streamlines industries, the aerospace sector struggles to keep pace with this change.

- Cybersecurity Threat: The growing concern of cyber attacks.

- Supply Chain Weaknesses: Vulnerabilities in the supply chain affecting production and distribution.

- Increasing Passenger Numbers: Managing the rising demand for air travel.

- Skills Shortage: The industry faces a shortage of skilled professionals to tackle its growing needs.

How are aerospace parts typically manufactured?

Milling stands out as a prevalent manufacturing technique in the aerospace industry, primarily used for making various cuts and shapes in work pieces. This can range from simple cuts to intricate designs and detailed layers. The most widely used milling processes include vertical milling, which is essential for creating precise components in aerospace manufacturing.

Can you explain what aerospace product and parts manufacturing involves?

The aerospace products and parts manufacturing sector is dedicated to the development and production of aircraft, aircraft components, missiles, and space vehicles. This industry encompasses a wide range of products essential for aviation and space exploration.

What does the NAICS code 33641 represent?

The NAICS code 33641 is designated for Aerospace Product and Parts Manufacturing. This code is used to classify businesses involved in the development and manufacturing of aerospace products, including aircraft and spacecraft components, among others.

In aircraft fuel systems, Delrin®’s

In aircraft fuel systems, Delrin®’s

In the aerospace parts manufacturing sector, the selection and processing of materials are driven by the industry’s unyielding pursuit of advancements in strength, weight reduction, and resistance to extreme conditions.

In the aerospace parts manufacturing sector, the selection and processing of materials are driven by the industry’s unyielding pursuit of advancements in strength, weight reduction, and resistance to extreme conditions.

Each of these polymers brings a unique set of properties to the table, making them highly suitable for the demanding requirements of aerospace cryogenic seals. Their combined characteristics of chemical resistance, thermal stability, low moisture absorption, and mechanical durability under extreme conditions position them as optimal materials for aerospace applications, where failure is not an option.

Each of these polymers brings a unique set of properties to the table, making them highly suitable for the demanding requirements of aerospace cryogenic seals. Their combined characteristics of chemical resistance, thermal stability, low moisture absorption, and mechanical durability under extreme conditions position them as optimal materials for aerospace applications, where failure is not an option.

2.3 Market Opportunities

2.3 Market Opportunities 4. Regional Analysis

4. Regional Analysis