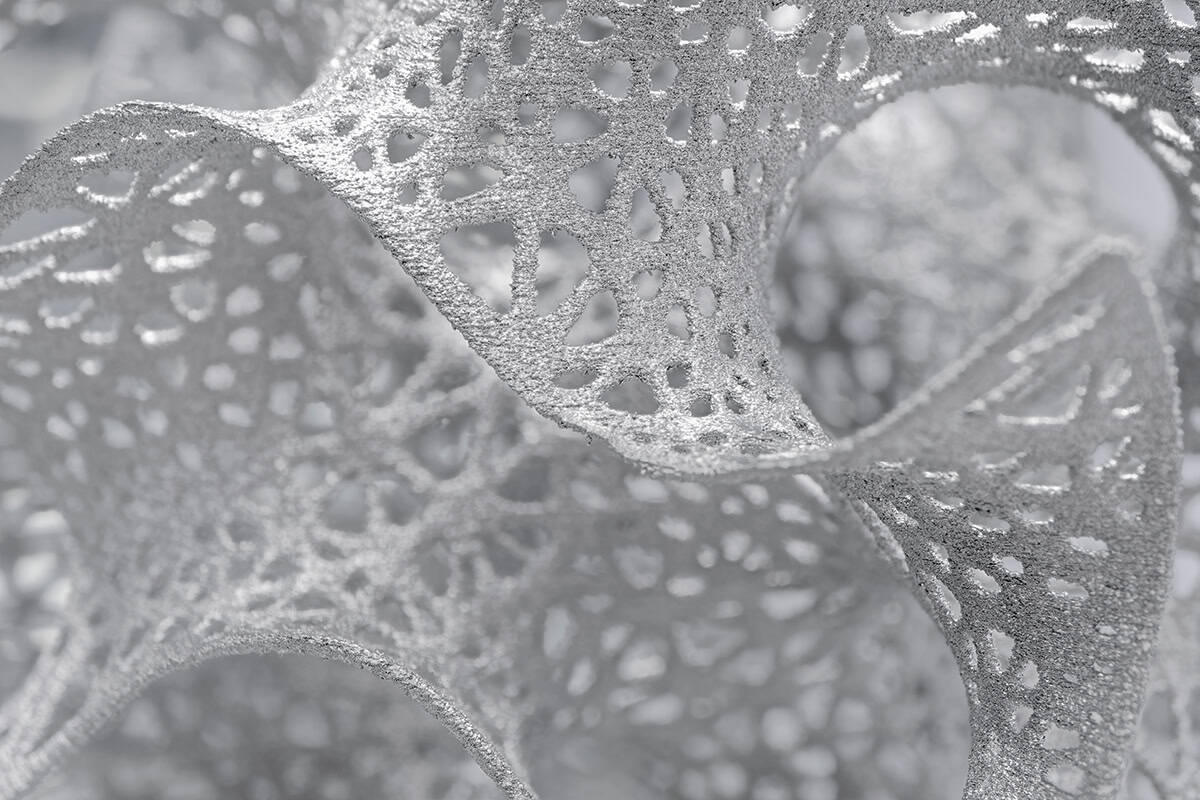

Additive manufacturing aerospace parts can reduce weight by up to 70% compared to equivalent components made from lightweight alloys such as aluminum. This weight advantage is particularly significant in the aerospace industry, where removing just one kilogram from an aircraft can save hundreds of liters of fuel over its lifetime. Unlike traditional manufacturing methods, additive technologies enable the production of complex geometries and intricate designs that would otherwise be difficult to achieve with conventional machining processes.

Additive manufacturing aerospace parts can reduce weight by up to 70% compared to equivalent components made from lightweight alloys such as aluminum. This weight advantage is particularly significant in the aerospace industry, where removing just one kilogram from an aircraft can save hundreds of liters of fuel over its lifetime. Unlike traditional manufacturing methods, additive technologies enable the production of complex geometries and intricate designs that would otherwise be difficult to achieve with conventional machining processes.

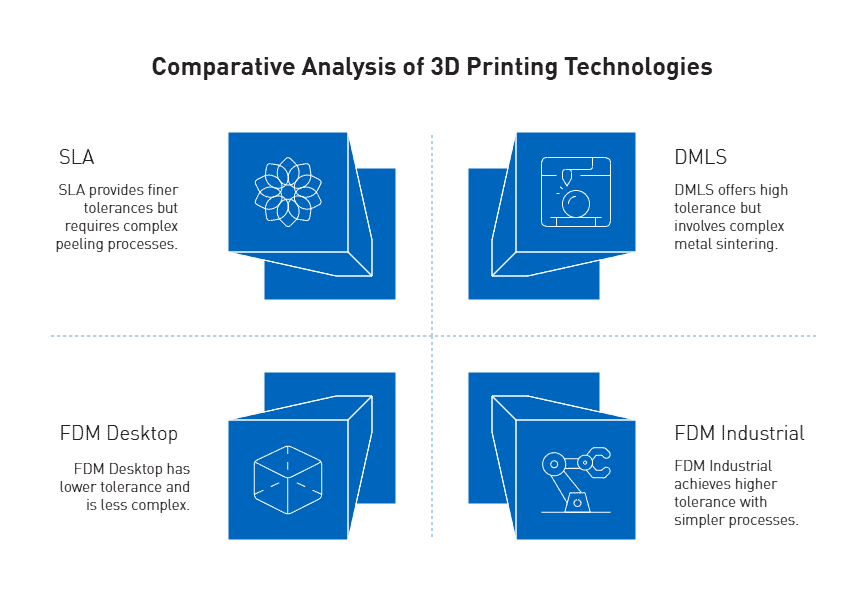

While 3D printing in aerospace continues to grow as the fastest expanding industrial technique, the decision between additive and subtractive manufacturing isn’t always straightforward. CNC machining typically involves higher initial setup costs but offers cost-efficiency for high-volume production.

However, traditional methods often result in a high “buy-to-fly” ratio, indicating that a significant portion of the initial material is removed during machining, leading to increased costs and environmental implications. Additionally, specific manufacturing methods like HP MJF, FDM, SLS, and DMLS provide flexibility for custom, low-volume, and complex parts, whereas CNC machining, injection molding, and sheet metal fabrication are better suited for high-precision, high-volume production.

This article explores the critical factors aerospace professionals should consider when deciding between additive and traditional manufacturing approaches for aerospace components.

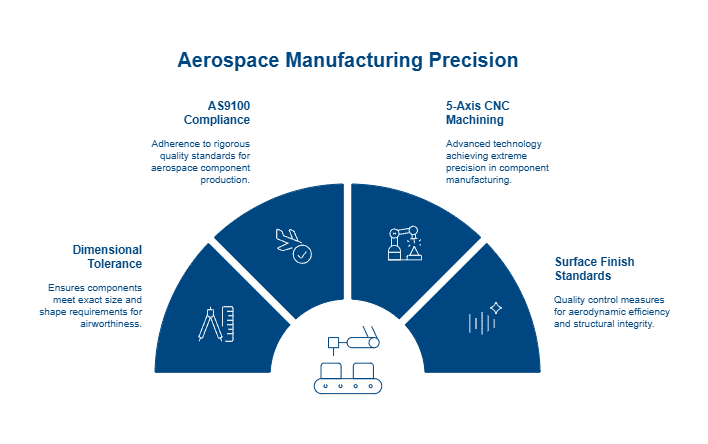

Dimensional Tolerance and Surface Finish Requirements in Aerospace

In aerospace manufacturing, precision is a fundamental requirement rather than an optional feature. The industry demands tight tolerances because even minor deviations can significantly compromise airworthiness. Consequently, understanding dimensional accuracy requirements becomes essential for selecting the appropriate manufacturing method.

AS9100 and FAA Compliance for Machined Components

The aerospace sector operates under rigorous quality standards that govern every aspect of component production. AS9100D certification, an enhancement of ISO 9001, adds specific requirements designed for aerospace manufacturing. This standard incorporates vital aspects like risk management, project management, and configuration management—making it a prerequisite for organizations supplying aerospace components. Furthermore, the Federal Aviation Administration (FAA) establishes comprehensive regulations through certification processes that ensure components meet design, operational, and safety standards. Manufacturers must maintain closed-loop quality control systems that guarantee compliance at every production stage.

5-Axis CNC Machining for Tight Tolerances

Five-axis CNC machining represents a significant advancement for achieving the extreme tolerances necessary in aerospace applications. This technology allows components to move in five directions simultaneously, reaching almost any angle without manual repositioning. For precision metal manufacturing, typical achievable tolerances fall within ±0.005″ to ±0.010″, depending on geometry, material, and orientation. The reduction in multiple setups leads to fewer alignment errors, resulting in parts that consistently meet strict specifications.

Surface Finish Standards for Flight-Critical Parts

Surface finish quality directly impacts multiple performance aspects of aerospace components, including:

- Aerodynamic efficiency – Surface roughness influences drag, lift generation, and pressure distributions, affecting flight stability

- Structural integrity – Even microscopic irregularities create stress concentrations that can initiate fatigue cracks under cyclic loading

- Corrosion resistance – Rougher surfaces provide more opportunities for corrosion initiation in micro-crevices

Surface roughness is typically measured using parameters like Ra (average roughness), Rq (root mean square roughness), and Rz (average maximum height). For critical components, metrology-grade inspection verifies that surface finishes meet specifications. Additionally, specialized post-manufacturing treatments—including etching, passivation, shot peening, and polishing—can optimize surface properties while maintaining dimensional accuracy.

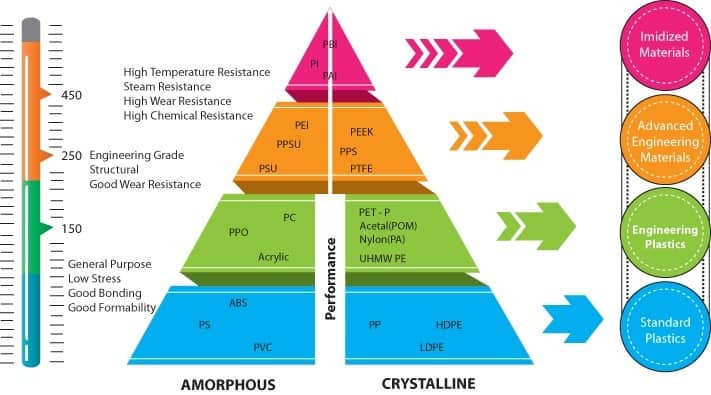

Material Selection: When Additive Manufacturing Excels

The selection of appropriate materials often determines whether additive manufacturing offers advantages over traditional machining methods. Modern high-performance polymers provide aerospace engineers with alternatives that excel in specific applications where weight reduction and complex geometries are essential.

High-Performance Thermoplastics: PEEK, ULTEM™, TORLON®

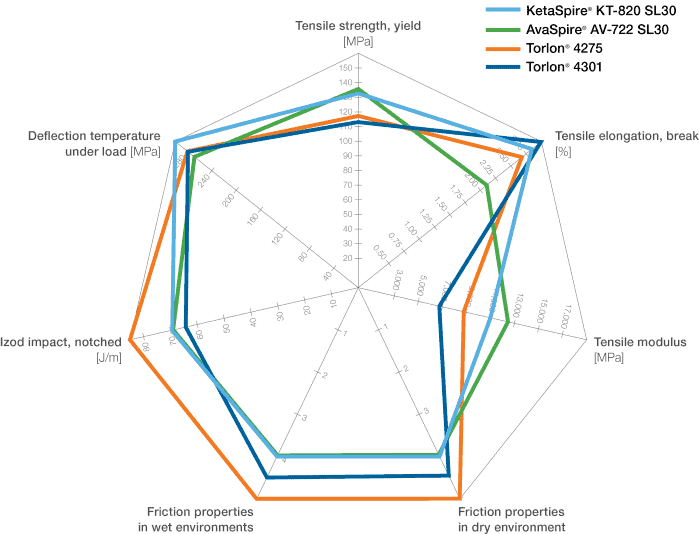

High-performance thermoplastics deliver exceptional mechanical properties while remaining up to 70% lighter than steel. Among these materials, PEEK (Polyetheretherketone) stands out with its remarkable melting point of approximately 343°C and continuous use temperature of 260°C. This semi-crystalline thermoplastic maintains its mechanical properties at elevated temperatures, making it ideal for applications requiring thermal stability. PEEK also demonstrates excellent resistance to chemicals, aircraft fuels, and steam without degradation.

ULTEM™ (Polyetherimide or PEI) offers an exceptional balance of flame retardance, low smoke emission, and toxicity compliance. With a glass transition temperature of 217°C, ULTEM™ maintains structural integrity in demanding thermal environments. Notably, ULTEM 9085 meets strict FAA regulations for flammability, making it particularly valuable for cabin interiors, ventilation systems, and food service equipment.

TORLON® (Polyamide-imide or PAI) delivers the highest tensile strength among non-filled, injection-moldable thermoplastics. With exceptional compressive strength ranging from 150 to 220 MPa, TORLON® maintains its mechanical properties at temperatures up to 260°C. Indeed, TORLON® outperforms other high-performance polymers under various extreme velocities and pressures.

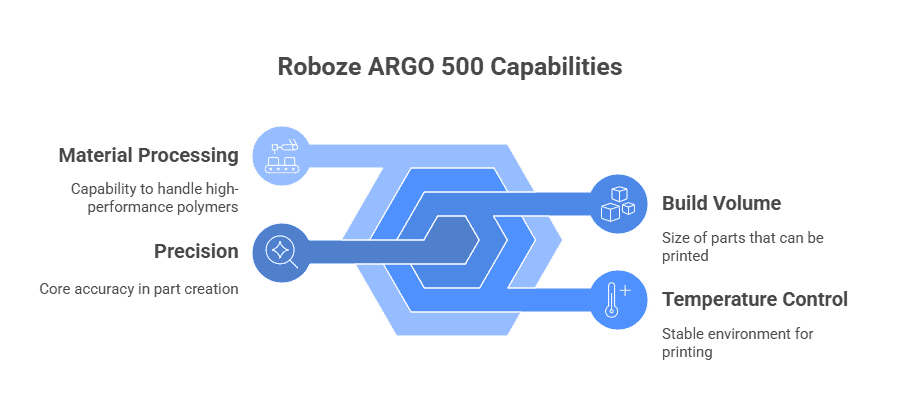

Roboze ARGO 500 for High-Temperature Polymers

The Roboze ARGO 500 represents advanced additive manufacturing technology specifically designed for super polymers like PEEK and Carbon PEEK. With its patented beltless system, this 3D printer achieves 10μm positioning precision in XY axes and maintains consistent repeatability essential for aerospace applications. The system’s high-temperature capabilities—500°C extrusion temperature and 180°C chamber temperature—enable proper crystallization of components, eliminating the need for external thermal post-processing.

Biocompatibility and Weight Reduction in Aerospace Polymers

Advanced aerospace polymers offer substantial weight reduction—up to 50% compared to metal parts—directly improving fuel efficiency and lowering operational costs. This weight advantage becomes especially significant considering that removing just one kilogram from an aircraft saves thousands of fuel liters over its lifetime.

Case studies demonstrate impressive results: replacing aluminum with composite thermoplastics resulted in a 50% weight reduction and 20% cost savings for aircraft storage bin brackets. Similarly, using Carbon PA instead of metal reduced the number of parts in a centering device by 92%. Essentially, these high-performance polymers enable designers to consolidate multiple components into single, lightweight parts with complex internal geometries that would be impossible to manufacture through traditional methods.

Production Volume and Lead Time Considerations

Production volume and lead time requirements often determine the optimal manufacturing approach for aerospace components. The selection of either additive or traditional methods depends on project specifications, with each offering distinct advantages at different scales of production.

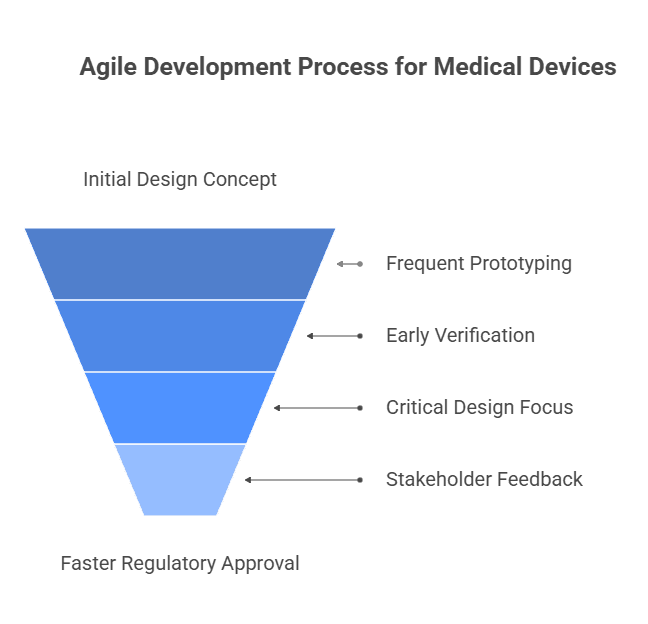

Rapid Prototyping with Additive Manufacturing

Additive manufacturing established its initial foothold in aerospace through rapid prototyping, enabling engineers to quickly validate designs before committing to production. This approach allows teams to transform digital models into physical prototypes without tooling requirements, accelerating the development cycle. For aerospace applications, 3D printing reduces prototype production time from weeks to mere days—or even hours—depending on component complexity. Moreover, prototyping with additive manufacturing creates opportunities for multiple design iterations, significantly reducing overall development costs.

Short-Run Custom Aerospace Components

For specialized aerospace components needed in limited quantities, additive manufacturing presents compelling economic advantages. The technology enables cost-effective production of short runs without the expense of tooling or molds. According to industry data, lead times for custom aerospace parts typically extend beyond 12 weeks with traditional manufacturing partners, yet additive manufacturing can deliver finished components weeks faster. Additionally, additive manufacturing demonstrates particular value for low-volume production where parts feature complex geometries or internal channels that would be impossible to produce through conventional methods.

High-Volume Production with CNC Machining

As production quantities increase, the economics generally shift toward traditional CNC machining. Modern multi-axis CNC systems offer unmatched consistency across thousands of identical parts. High-volume CNC machining integrates multiple functions into single units, allowing a solitary multi-axis machine to replace entire production lines. This consolidation creates substantial benefits, primarily through reduced facility requirements, decreased labor costs through automation, and lower error rates. Subsequently, high-volume aerospace manufacturers value suppliers with vertical integration capabilities that control quality across multiple manufacturing processes.

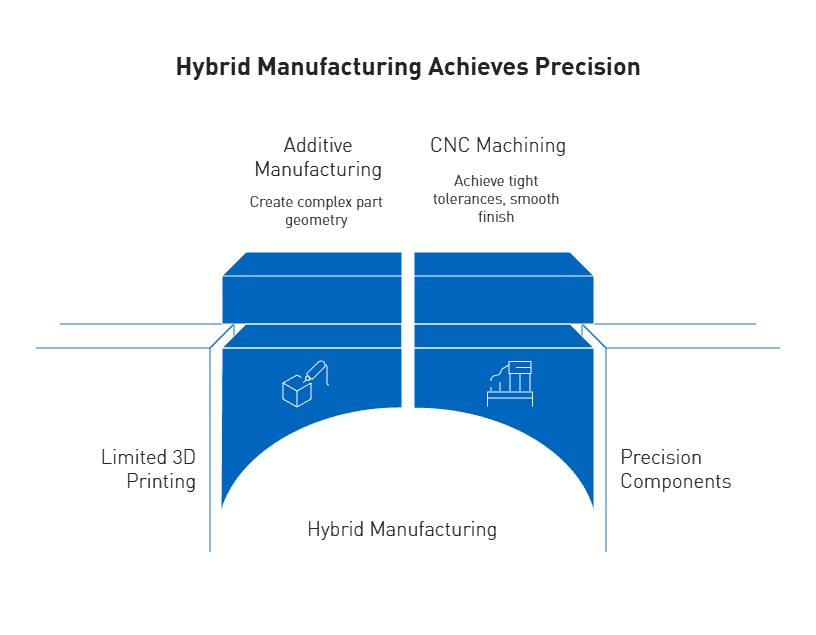

Hybrid Manufacturing for Complex Aerospace Parts

Hybrid manufacturing emerges as a strategic approach in aerospace by integrating additive and subtractive technologies into a cohesive process. This methodology capitalizes on the distinct advantages of each manufacturing technique for optimal results.

Additive-Subtractive Integration for Internal Channels

Complex internal geometries that remain inaccessible to conventional machining now become feasible through hybrid manufacturing. Alternating between additive and subtractive processes allows for the creation of intricate internal features by machining them as they are printed. For aerospace applications, this integration enables manufacturers to produce components with conformal cooling channels, lightweight internal structures, and complex passageways. The aerospace sector leads implementation of this technology, primarily due to demanding performance requirements.

Precision Polymer Components with Post-Machining

High-performance polymers often require post-machining to achieve aerospace-grade tolerances. Modern CNC systems can consistently achieve tolerances of 0.001 inches on polymer components. Appropriate tooling selection, controlled spindle speeds, and specialized cutting parameters prove essential for successful results, as polymers behave differently than metals under machining conditions. Post-processing techniques—including finishing machining, vibrating surface finishing, and drag finishing—significantly enhance surface quality.

Hybrid Use Cases: Brackets, Ducts, and Mounts

The integration of additive-subtractive methods excels in producing airframe brackets, structural supports, and engine components that meet rigorous aviation standards. Complex aerospace components processed through hybrid manufacturing demonstrate deviation rates under 10% compared to predicted geometry, confirming the approach’s reliability for flight-critical applications.

Conclusion

Aerospace professionals face increasingly complex choices when deciding between additive and traditional machining. Additive manufacturing offers compelling advantages in weight reduction, design freedom, and short-run efficiency, particularly when using high-performance polymers like PEEK, ULTEM™, and TORLON®. These materials enable parts that are lighter, corrosion-resistant, and capable of withstanding extreme temperatures—critical for modern aerospace applications.

However, CNC machining remains the standard for components requiring ultra-tight tolerances, AS9100D and FAA compliance, and high-volume production stability. The growing adoption of hybrid manufacturing—which combines both additive and subtractive methods—provides a best-of-both-worlds solution, especially for complex geometries and conformal cooling features.

Not sure which path is right for your part? Request a consultation with AIP Precision Machining. Our experts will guide you through design for manufacturability, material selection, and regulatory compliance for your aerospace program.

FAQs

Q1. What are the main advantages of additive manufacturing in aerospace?

Additive manufacturing in aerospace offers significant weight reduction (up to 70% compared to metal parts), enables the creation of complex geometries, and allows for rapid prototyping and production of custom, low-volume parts. These benefits contribute to improved fuel efficiency and reduced development costs.

Q2. When is traditional CNC machining preferred over additive manufacturing in aerospace?

CNC machining is typically preferred for high-volume production, components requiring ultra-precise tolerances, and flight-critical parts that need to meet strict AS9100D and FAA compliance standards. It offers consistent quality across large production runs and is often more cost-effective for high quantities.

Q3. What are some key high-performance thermoplastics used in aerospace additive manufacturing?

PEEK, ULTEM™, and TORLON® are prominent high-performance thermoplastics used in aerospace additive manufacturing. These materials offer excellent thermal stability, chemical resistance, and strength-to-weight ratios, making them suitable for demanding aerospace applications.

Q4. How does hybrid manufacturing benefit the aerospace industry?

Hybrid manufacturing, which combines additive and subtractive technologies, allows for the creation of complex aerospace components with internal channels, conformal cooling systems, and intricate passageways. This approach enables manufacturers to achieve optimal results in weight reduction, performance enhancement, and operational efficiency.

Q5. What factors should be considered when choosing between additive and traditional manufacturing for aerospace parts?

Key factors to consider include dimensional tolerance requirements, material properties, production volume, lead time, component complexity, weight reduction goals, and compliance with industry standards. The specific project requirements and desired outcomes should guide the decision between additive and traditional manufacturing methods.

In the aerospace parts manufacturing sector, the selection and processing of materials are driven by the industry’s unyielding pursuit of advancements in strength, weight reduction, and resistance to extreme conditions.

In the aerospace parts manufacturing sector, the selection and processing of materials are driven by the industry’s unyielding pursuit of advancements in strength, weight reduction, and resistance to extreme conditions.

There’s no doubt that plastics have become more and more popular in modern medicine. Short lead times are essential in this industry, and both 3D additive manufacturing and CNC machining provide fast production times. When is your medical application better suited for 3D printing, though, and when does precision plastic machining have the upper hand in plastic manufacturing?

There’s no doubt that plastics have become more and more popular in modern medicine. Short lead times are essential in this industry, and both 3D additive manufacturing and CNC machining provide fast production times. When is your medical application better suited for 3D printing, though, and when does precision plastic machining have the upper hand in plastic manufacturing?