An Informational Brief on Polymer Machining

The recent popularity of PEEK (polyetheretherketone) in complex industries such as Aerospace & Defense and Medical & Life Sciences is well documented, and for good reason: this lightweight thermoplastic bears properties that make it ideal for a variety of specialized applications. This versatility makes PEEK equally capable of being used for implants and custom medical devices or machined lightweight aircraft components.

What is less known, however, is the process that goes into machining this plastic material. With over 35 years of experience machining this thermoplastic material, we at AIP have written a brief introduction to machining PEEK. We hope this gives you some insight into our polymer machining process, and how it differs from that of metal machining or injection molding.

Plastic CNC Machining

Before discussing the process of machining PEEK, it’s important to understand exactly what plastic machining is.

CNC (Computer Numerical Control) machining is a process in the manufacturing sector that involves the use of computers to control machine tools. In the case of plastic machining, this involves the precise removal of layers from a plastic material. The technique of utilizing drilling tools to carve plastics was introduced by MIT during the 1950s, and because this process is computer-controlled, products with extremely precise tolerances can be achieved.

Due to the many different kinds of polymers and composites, it’s important to have strong technical expertise of polymer materials when machining plastic components; some plastics are brittle, for example, while others cut similarly to metal. The challenge of plastics is their wide range of mechanical properties and varying behavior when machined. Therefore, it’s important to understand the polymer structure of PEEK if you’re machining it.

Thermoplastics vs Thermosets

When it comes to polymers, you have two basic types: thermoplastics and thermosets. It’s crucial to know which one you’re working with due to distinct differences between how those polymers react to heat and temperature.

Thermoplastics are capable of being repeatedly softened and pliable when temperature increases, meaning that when heat is applied, that results in a physical change for the polymer. They possess the following properties:

- – Good Resistance to Creep

- – May Melt Before Turning to Gaseous State

- – Soluble in Certain Solvents

- – Swell in Presence of Certain Solvents

- – Allows for Plastic Deformation when Heated

Thermosets, in contrast, turn into an infusible and insoluble material when cured by application of heat or chemical means, making for poor elasticity. They possess the following properties:

- – High Resistance to Creep

- – Cannot Melt

- – Insoluble

- – Rarely Swell in Presence of Solvents

Phenolic materials would be considered examples of a thermoset, while PEEK is an example of a thermoplastic.

In particular, PEEK is considered a semi-crystalline, high-performance thermoplastic. This gives it enough elasticity to be machined to various custom designs, with strong mechanical properties that provide resistance to fatigue and stress-cracking, as well as a good structure for bearing, wear, and structural applications.

Industrial Grade vs Medical Grade PEEK Machining

Depending on your application, you’ll want to machine either industrial-grade PEEK or medical-grade PEEK.

Industrial-grade PEEK is a strong, flame-retardant and abrasion resistant thermoplastic with high impact strength and a low coefficient of friction. It’s known for retaining its mechanical properties, even at elevated temperatures. As suggested by its name, this grade is most commonly used in aerospace, automotive, chemical, electronics, petroleum, as well as food and beverage industries.

Medical-grade PEEK adds biocompatibility per ISO 10993, high chemical resistance, and sterilization compatibilities to the above list of qualities. In addition, this thermoplastic is radiolucent, meaning it is not visible under X-ray, MRI or CT. Medical-grade PEEK includes polymers suitable for implants, such as PEEK Optima and Zeniva PEEK, which can stay in contact with blood or tissue indefinitely while mimicking the stiffness of bone. Other variations of medical-grade PEEK can be used for custom medical components and applications, such as articulating joints and spinal devices.

Machining PEEK

Annealing PEEK

Most shops receive PEEK in the form of rods of various lengths, ranging from 6mm to 150mm in diameter. Stress-relieving before machining through an annealing process is crucial, as it reduces the likelihood that surface cracks and internal stresses will occur from the heat generated. Additional benefits of annealing include increased levels of crystallinity and the opportunity to limit dimensional changes.

If your PEEK components will undergo long stretches of machining time, it is likely you will require additional intermediate annealing steps to assure the ability to maintain critically tight tolerances and flatness.

Machining Industrial-Grade & Medical-Grade PEEK

Both industrial-grade and most medical-grade PEEK machine similarly, save for PEEK reinforced with carbon fiber. Silicon carbide cutting tools work well for natural PEEK, while diamond tools work well for PEEK reinforced with carbon-fiber.

For medical-grade PEEK applications, the best way to avoid jeopardizing the biocompatibility of the material is to machine dry. However, PEEK doesn’t dissipate heat the way that metals do, so often a coolant is necessary. In that case, air is the coolant option least likely to affect medical-grade PEEK’s biocompatibility. Any chips that are a result of machining medical-grade PEEK can be reused for industrial applications.

Preventing Contamination

Contamination is a serious concern when machining polymer components for technically demanding industries such as aerospace and medical. To ensure the highest level of sanitation down to the sub-molecular level, AIP Precision Machining designs, heat-treats, and machines only plastics, with any sub-manufactured metalwork processed outside our facility.

PEEK Machining Guide: Guidelines

(Courtesy of Invibio)

Natural PEEK |

Carbon-Fiber-Reinforced PEEK |

blank |

| Sawing | blank | Preheat material to 120 C degrees |

| Clearance angle—degrees | 15 to 30 | 15 to 30 |

| Rake angle—degrees | 0 to 5 | 10 to 15 |

| Cutting speed—m/min | 500 to 800 | 200 to 300 |

| Pitch—mm | 3 to 5 | 3 to 5 |

| Drilling | blank | Preheat material to 120 C degrees |

| Clearance angle—degrees | 5 to 10 | 6 |

| Rake angle—degrees | 10 to 30 | 5 to 10 |

| Cutting speed—m/min | 50 to 200 | 80 to 100 |

| Feed rate—mm/rev | 0.1 to 0.3 | 0.1 to 0.3 |

| Milling | blank | No material preheat is necessary |

| Clearance angle—degrees | 5 to 10 | 15 to 30 |

| Rake angle—degrees | 10 to 30 | 10 to 15 |

| Cutting Speed—m/min | 50 to 200 | 200 to 300 |

| Turning | blank | No material preheat is necessary |

| Clearance angle—degrees | 6 to 8 | 6 to 8 |

| Rake angle—degrees | 0 to 5 | 2 to 8 |

| Cutting speed—m/min | 250 to 500 | 150 to 200 |

| Feed rate—mm/rev | 0.1 to 0.5 | 0.1 to 0.5 |

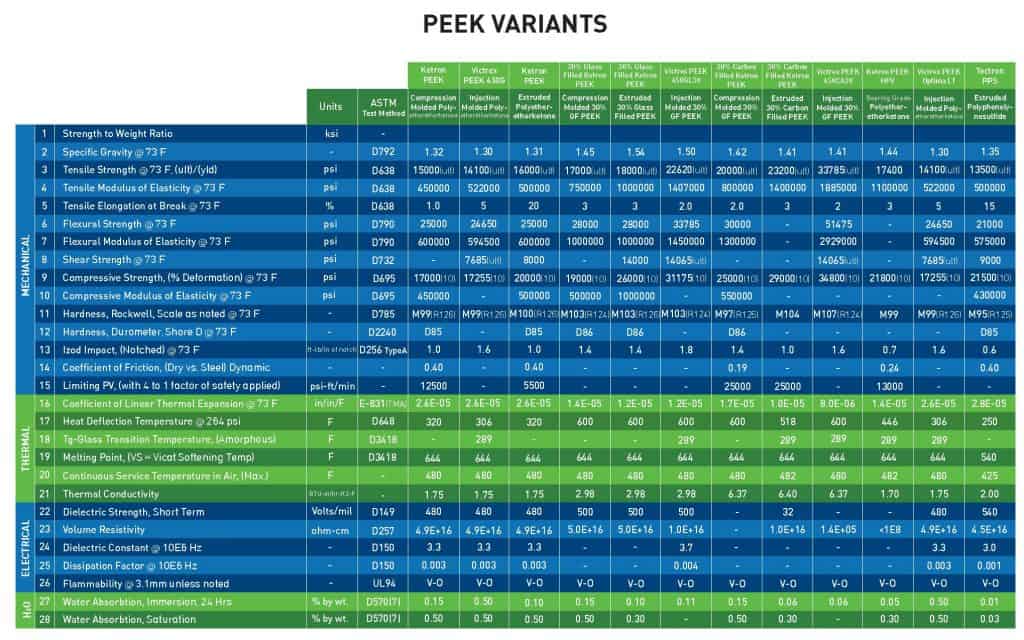

PEEK Machining Guide: PEEK Variants