Hybrid manufacturing technology reduces total production costs by 35% and shortens complex parts processing cycles by 50% compared to traditional methods. This revolutionary approach combines 3D printing (additive manufacturing) and CNC machining (subtractive manufacturing) to create superior medical machined components with unmatched precision and efficiency. The integration of these complementary technologies addresses the limitations of each individual method while maximizing their respective strengths.

When creating precision medical components, manufacturers face significant challenges with traditional production methods. CNC machining alone delivers exceptional accuracy but struggles with complex internal geometries and is more labor-intensive. On the other hand, 3D printing offers remarkable flexibility for design alterations without additional equipment setup. By combining additive and subtractive processes, medical device CNC machining achieves the best of both worlds—the design freedom of 3D printing with the precision finishing of multi-axis machining. Additionally, this hybrid approach optimizes surface quality from Ra30μm in selective laser melting to Ra0.4μm, meeting the stringent requirements for medical device implantation.

Precision machining ensures accuracy and consistency in crafting intricate medical components, allowing for the production of complex parts that meet the high standards required in the medical industry. Furthermore, advanced materials used in precision machining enhance the durability and reliability of these critical medical components. This combination of technologies represents the future of medical parts machining, offering unprecedented design possibilities while maintaining the exacting tolerances essential for patient safety.

How CNC and 3D Printing Work Together in Medical Machining

The synergy between additive and subtractive manufacturing creates a powerful methodology for producing precision medical components. This collaborative approach enables manufacturers to create intricate internal structures with 3D printing before achieving precise shapes and surface finishes through CNC machining.

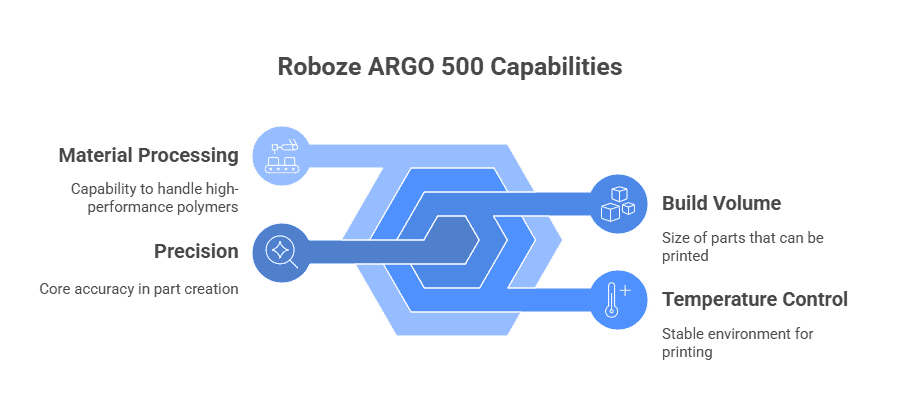

Near-Net Shaping with Roboze ARGO 500

The Roboze ARGO 500 represents a significant advancement in medical component manufacturing. This industrial-grade 3D printer creates near-net shaped parts with 10μm positioning precision in the XY axis and handling build volumes up to 500x500x500 mm.

The system’s patented beltless technology ensures low surface roughness and CNC-grade accuracy while requiring minimal maintenance. Operating with extrusion temperatures reaching 500°C, it effectively processes high-performance polymers essential for medical applications. The system’s controlled environment maintains chamber temperatures up to 180°C, enabling stable prints with built-in annealing characteristics.

Precision Finishing with Multi-Axis CNC

Following the additive process, multi-axis CNC machining transforms the near-net shaped components into finished medical products. This subtractive technique enhances dimensional accuracy and surface quality – critical factors for medical device functionality. The process effectively takes 3D-printed parts with relatively rough surface finishes (Ra30μm) and refines them to medical-grade smoothness (Ra0.4μm). Multi-axis CNC machining particularly excels at creating precise geometries, tight tolerances, and sterilization-compatible surfaces necessary for implantable devices and surgical instruments.

Post-Processing for Sterilization-Ready Surfaces

Post-processing represents the final critical stage in hybrid medical manufacturing. Throughout this phase, components undergo precision cleaning and finishing operations specifically designed for medical-grade requirements. Proper post-processing ensures medical components can withstand rigorous sterilization protocols without degradation. The hybrid approach enables manufacturers to optimize surface characteristics for both functional performance and biocompatibility.

This integrated methodology significantly improves production efficiency, with studies showing hybrid manufacturing can reduce costs by 4-9% compared to conventional methods. Moreover, the approach creates excellent structures for osseointegration in implantable components. By combining these complementary technologies, manufacturers achieve superior results impossible with either technology alone.

Why Hybrid Manufacturing Outperforms Traditional Methods

Medical device manufacturers are consistently seeking manufacturing methods that offer distinct advantages over conventional approaches. The convergence of CNC machining and 3D printing in hybrid manufacturing delivers several key benefits for precision medical components.

Design Flexibility for Complex Geometry Medical Components

Hybrid manufacturing excels in creating intricate medical geometries that would be impossible or cost-prohibitive using traditional methods alone. This process allows for internal channels, lattice structures, and organic shapes that are essential in medical applications. Unlike conventional methods, hybrid approaches enable designers to build components with complex internal features first through additive manufacturing, consequently refining external surfaces with CNC machining. This dual capability is particularly valuable for customized prosthetics and implants where internal structures affect both weight and functionality.

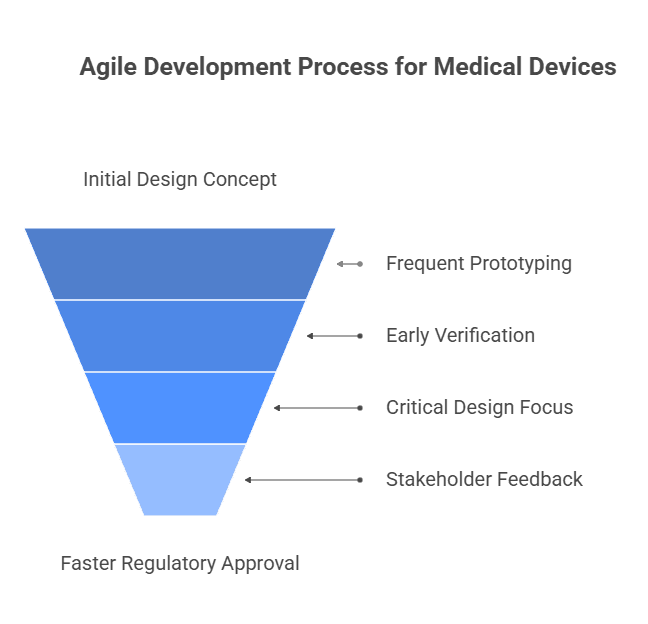

Speed to Market with Agile Prototyping

The agile methodology inherent in hybrid manufacturing drastically reduces development cycles for medical devices. Working prototypes are produced frequently throughout development, enabling early verification through unit tests and iterative manual validation.

This approach allows manufacturers to identify and tackle critical design aspects first, hence reducing product risk. Medical device companies utilizing agile development report faster regulatory approval pathways since designs can be quickly modified based on stakeholder feedback without restarting the entire process.

Cost Efficiency in Low-Volume Production

For medical components typically produced in smaller quantities, hybrid manufacturing presents compelling financial advantages:

- Elimination of expensive tooling costs required in traditional manufacturing

- Reduced inventory carrying costs through on-demand production

- Lower overall production costs—between 4-9% compared to conventional methods

Enhanced Mechanical Properties in Super Polymers

Super polymers processed through hybrid manufacturing maintain exceptional performance characteristics even in extreme conditions. Materials like PEEK demonstrate remarkable thermal versatility, functioning across wide temperature ranges while retaining structural stability. In fact, when properly processed through hybrid methods, these components can achieve tensile strength approximately 71.6% of injection-molded equivalents. This combination of strength, biocompatibility, and radiolucence makes hybrid-manufactured components ideal for applications where both mechanical properties and patient monitoring are crucial.

Material Considerations for Medical Hybrid Manufacturing

Selecting appropriate materials remains a critical factor in successful hybrid manufacturing for medical applications. The unique combination of additive and subtractive processes demands materials that maintain integrity throughout both production stages.

PEEK and PPSU: Biocompatibility and Sterilization Compatibility

PEEK (Polyetheretherketone) stands out as an exceptional polymer for medical applications, offering biocompatibility for implants with ISO 10993 certification and a modulus similar to human cortical bone. This material demonstrates remarkable sterilization resistance, withstanding over 1,500 steam autoclave cycles without significant property degradation. PPSU (Polyphenylsulfone) surpasses other sulfone-based polymers with impact resistance measuring up to 13 ft-lbs/in. Radel PPSU maintains its properties after 1,000 autoclave cycles, making it ideal for reusable medical instruments.

Torlon Medical Applications for High-Load Environments

Torlon PAI (Polyamideimide) delivers unmatched performance among melt-processable thermoplastics. Its compressive strength doubles that of PEEK when unfilled. Torlon’s exceptional wear resistance ensures longevity in peristaltic pump rollers and prosthetic bushings. Medical grade Torlon offers high modulus, radiolucency, sterilization compatibility, and superior dimensional stability across its entire service temperature range.

Machining Radiolucent and Implantable Polymers

Implantable medical devices require biocompatible materials that serve functions for 30+ days. PEEK’s radiolucent properties allow unobstructed imaging through MRI, X-rays, and CT scans. Carbon fiber reinforcement can boost structural strength for load-bearing applications. Additionally, barium sulfate additives increase radiopacity for surgical monitoring without affecting biocompatibility.

Contamination Control in Polymer-Only Machining Environments

Dedicated polymer-only machining environments essentially eliminate metallic cross-contamination risks. Medical components require strict adherence to ISO 13485 and FDA standards for quality management. Ensuring sterilization begins with selecting manufacturers committed to preventing contamination at even sub-molecular levels.

AIP Precision Machining: Certified Excellence in Medical Manufacturing

For three decades, AIP Precision Machining has established itself as a leader in producing advanced medical machined components. Their commitment to quality extends throughout their entire manufacturing process, from initial concept through final delivery.

ISO 13485 and FDA-Registered Facility Standards

AIP operates under ISO 13485:2016 compliance and maintains FDA registration status, having successfully passed audits from the most demanding orthopedic and medical device OEMs. These certifications reflect their adherence to the international standard specifically designed for medical device quality management systems. This regulatory framework ensures consistent quality, proper documentation, and risk-based decision making throughout the manufacturing process.

±0.002 mm Tolerance Capabilities

Precision defines AIP’s manufacturing approach, with tolerance capabilities reaching ±0.002 mm. This exceptional accuracy allows their team to machine custom medical components within ten-thousandths of an inch or less. Such precision is crucial for components like surgical instruments, implantable prototypes, and diagnostic equipment where micron-level tolerances are mandatory rather than optional.

Dedicated Polymer-Only Machining Environment

AIP exclusively machines plastics, thereby eliminating the risk of metallic cross-contamination. This dedicated approach proves especially valuable for biocompatible applications where material purity directly impacts patient safety. Their specialized environment maintains strict hygienic procedures throughout the manufacturing process.

Roboze ARGO 500 for High-Performance Additive Manufacturing

The integration of Roboze ARGO 500 technology into AIP’s capabilities elevates their hybrid manufacturing potential. This system delivers 10μm positioning precision in XY axis, creating large-format parts with industrial-grade accuracy and exceptional dimensional repeatability. The system’s beltless technology ensures CNC-grade precision throughout the additive process.

Schedule a Design-for-Manufacturing Consultation – Partner with our engineering team at AIP to optimize your part for both additive and CNC production.

Conclusion

The future of medical component manufacturing clearly belongs to hybrid manufacturing technologies. This integrated approach effectively addresses the limitations of traditional methods while delivering unprecedented precision and efficiency. Companies accordingly benefit from 35% lower production costs and 50% shorter processing cycles, particularly essential for time-sensitive medical innovations.

Medical devices demand exacting standards that hybrid manufacturing consistently meets through its complementary processes. CNC machining brings ±0.002 mm tolerance capabilities, while additive technologies create previously impossible internal geometries. Together, these technologies transform surface quality from Ra30μm to medical-grade Ra0.4μm finishes.

Super polymers processed through this hybrid methodology maintain exceptional performance characteristics across challenging medical environments. PEEK demonstrates remarkable biocompatibility with ISO 10993 certification, while PPSU withstands 1,000 autoclave cycles without degradation. Torlon PAI similarly excels with compressive strength doubling that of PEEK, making these materials ideal for demanding medical applications.

AIP Precision Machining stands at the forefront of this manufacturing revolution with three decades of specialized experience. Their ISO 13485:2016 compliance and FDA registration guarantee adherence to stringent quality management systems. The dedicated polymer-only environment eliminates cross-contamination risks, thus ensuring patient safety remains paramount throughout production.

The combination of Roboze ARGO 500 technology and multi-axis CNC capabilities provides medical device manufacturers unprecedented design freedom. This approach especially benefits complex geometries, customized implants, and specialized surgical instruments that traditional manufacturing methods struggle to produce efficiently.

Medical component development teams should therefore consider partnering with AIP for their next project. Their expertise spans the entire production process from initial design consultation through final quality verification. Schedule a design-for-manufacturing consultation today to discover how hybrid manufacturing technologies can optimize your medical components for both performance and production efficiency.

Key Takeaways

Hybrid manufacturing combining CNC machining and 3D printing is revolutionizing medical component production, delivering superior results that neither technology can achieve alone.

- Hybrid manufacturing reduces costs by 35% and shortens processing cycles by 50% compared to traditional methods while achieving medical-grade surface finishes.

- Complex internal geometries become possible through 3D printing’s design freedom, followed by CNC machining’s precision finishing for tight tolerances.

- Super polymers like PEEK and PPSU maintain exceptional biocompatibility and can withstand over 1,000 sterilization cycles without degradation.

- Dedicated polymer-only machining environments eliminate metallic contamination risks while maintaining ISO 13485 and FDA compliance standards.

- Tolerance capabilities reach ±0.002 mm precision with surface quality improvements from Ra30μm to Ra0.4μm for implantable medical devices.

This manufacturing approach particularly excels in low-volume medical device production, enabling rapid prototyping and customized implants while meeting the stringent quality requirements essential for patient safety and regulatory approval.

FAQs

Q1. How does hybrid manufacturing combine CNC machining and 3D printing for medical components?

Hybrid manufacturing integrates 3D printing for creating complex internal geometries and near-net shapes, followed by CNC machining for precision finishing. This combination allows for intricate designs with tight tolerances and medical-grade surface finishes, achieving results impossible with either technology alone.

Q2. What are the key advantages of hybrid manufacturing over traditional methods for medical devices?

Hybrid manufacturing offers several benefits: 35% lower production costs, 50% shorter processing cycles, greater design flexibility for complex geometries, faster prototyping, and cost-efficiency in low-volume production. It also allows for enhanced mechanical properties in super polymers used for medical applications.

Q3. Which materials are commonly used in hybrid manufacturing for medical components?

Common materials include PEEK and PPSU for their biocompatibility and sterilization resistance, Torlon PAI for high-load environments, and various radiolucent and implantable polymers. These materials maintain their integrity throughout both additive and subtractive manufacturing processes.

Q4. How does hybrid manufacturing improve surface quality for medical components?

Hybrid manufacturing can significantly improve surface quality, transforming 3D-printed parts with relatively rough surface finishes (Ra30μm) to medical-grade smoothness (Ra0.4μm) through precision CNC machining. This level of surface refinement is crucial for implantable devices and surgical instruments.

Q5. What certifications are important for manufacturers using hybrid technologies for medical components?

Manufacturers should adhere to ISO 13485:2016 standards for medical device quality management systems and maintain FDA registration. These certifications ensure consistent quality, proper documentation, and risk-based decision making throughout the manufacturing process, which is crucial for medical device production.