An Informational Brief on Polymer Machining

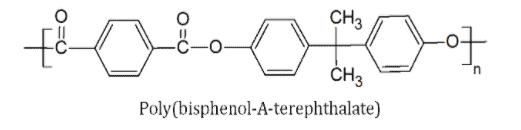

ARDEL® Polyarylates are a family of aromatic polyesters. It has inherent UV stability and superior retention of optical and mechanical properties. These qualities combined make it an excellent choice for applications where weathering and wear are a concern. To make a comparison, polyaryls have similar mechanical properties to polycarbonates. Likewise, its impact strength can be compared to medium-impact ABS.

AIP has over 37 years of experience machining complex components from thermoplastics like ARDEL® Polyarylate. In this insightful technical brief, we will discuss what goes into machining ARDEL® Polyarylate and how it differs from other manufacturing options such as metal machining, injection molding, and 3D printing.

Properties of ARDEL® Polyarylate

It is helpful to keep information on the properties of a thermoplastic before machining. This helps in selecting the right material for your project. Also, it assists in evaluating if the material is a candidate for the end-use requirement. Below are some of the key characteristics of ARDEL® Polyarylate:

Key Properties

|

|

ARDEL® Polyarylate is specifically formulated to endure extreme UV light. When exposed to UV, ARDEL® Polyarylate undergoes a molecular rearrangement resulting in the formation of a protective layer (UV stabilizer).

This high UV resistance makes ARDEL® Polyarylate the ideal material for any application where weathering effects could pose a problem. ARDEL provides for long lasting components in automated UV curing equipment.

Further, this material also offers good dimensional stability, chemical resistance and optical characteristics.

| Material Property | Units | Value |

| Tensile Elongation at Break @73 F | % | 10 |

| Flexural Modulus of Elasticity @ 73 F | psi | 310000 |

| Tensile Modulus of Elasticity @ 73 F | psi | 300000 |

| Flexural Strength @ 73 F | psi | 11000 |

| Density | g/cm3 lb/in3 |

1.21 0.044 |

| Tensile Strength @73 F, (ult)/(yld) | psi | 10000/(ult) |

| Notched Izod Impact @73 F | ft-lb/in of notch | 3.8 |

| Heat Deflection Temperature @ 264 psi | F | 345 |

| Flammability Rating | UL94 | V-0 |

| Coefficient of Linear Thermal Expansion @73 F | in/in/F | 3 |

| Dielectric Strength, Short Term | Volts/mil | 400 |

| Water Absorption 24 hours | % by weight | 0.26 |

Applications of ARDEL® Polyarylate

As mentioned previously, arylates are a good choice where weathering effects are an issue. Since they have excellent mechanical and electrical properties and excellent chemical stability, arylates are used in a variety of applications including automobiles, precision and medical devices, electronic displays and other electrical parts. Other parts include semiconductor molding compounds, decorative displays and protective coverings. Finally, with excellent resistance to degradation from ultraviolet radiation, ARDEL® Polyarylate can be found in solar-energy panels.

Common Applications

- Automotive Applications

- Connectors

- Electrical Parts

- Protective Coverings

AIP Machining Capabilities: Unrivaled Expertise

Our close ties with the industry’s leading plastics manufacturers give us even further insight and access to technical help in material selection, sizing and manufacturing procedures. Whatever your application, our machinists can help you in material selection, sizing and manufacturing techniques from concept to completion.

Machining ARDEL® Polyarylate

Annealing ARDEL® Polyarylate

As with any CNC machined part, annealing and stress-relieving is crucial to the machining process. Coolants, lubricants and trained procedures prevent cracking and crazing in a precision machined part. We recommend slow heating and cooling during the annealing process of thermoplastics. Our process at AIP significantly reduces the chances of these stresses occurring from the heat generating during machining ARDEL® Polyarylate. Our machinists use computer controlled annealing ovens for the highest quality precision temperatures and time control.

Machining ARDEL® Polyarylate

ARDEL® Polyarylate is one of the most dimensionally stable plastic materials to machine with a score of 3 (1 being easy and 10 being difficult), especially when trying to maintain tight tolerances or flatness. For the best results, use sharp tools, avoid excessive clamping and cutting forces and use coolants to prevent overheating. We recommend non-aromatic, water-soluble coolants because they are most suitable for ideal surface finishes and close tolerances. These include pressurized air and spray mists. Coolants have the additional benefit of extending tool life as well.

Some companies machine both metals and plastics, which has detrimental outcomes for machined polymer products. Many past experiences have shown parts going to customer without cracks, only to develop surface cracks and warping over time due to exposure to metal machine shop fluids. Be sure to use a facility like AIP that only machines polymers.

Preventing Contamination

Contamination is a serious concern when machining polymer components for technically demanding industries such as aerospace and medical sciences. To ensure the highest level of sanitation down to the sub-molecular level, AIP Precision Machining designs, heat-treats, and machines only plastics with any sub-manufactured metalwork processed outside our facility. This allows us to de-risk the process from metallic cross contamination.

ARDEL® Polyarylate Machining Guide: Supportive Information

Quality Assurance Certifications

Looking for more machining guides on performance thermoplastics?