Aerospace polymers significantly reduce aircraft weight by 50% compared to metal parts, revolutionizing how manufacturers approach structural component design. This weight reduction directly translates to improved fuel efficiency and substantially lower operational costs across the aviation industry. Furthermore, the global aerospace plastics market reached $7.61 billion in 2023 and is projected to grow to $13.89 billion by 2030, highlighting the increasing importance of these materials.

High-performance thermoplastics like PEEK, ULTEM®, and Vespel® offer unique advantages that make them ideal for aerospace applications. PEEK maintains its structural integrity at temperatures as high as 480 degrees Fahrenheit and demonstrates outstanding resistance to chemicals, aircraft fuels, and steam without degradation. Meanwhile, ULTEM® (polyetherimide) boasts an excellent strength-to-weight ratio, while plastic aerospace components can reduce manufacturing time by 80% — from hours to minutes.

This technical comparison examines the thermal, mechanical, and flame-resistant properties of these three high-performance aerospace grade polymers, specifically focusing on their applications in cabin interiors, flight control systems, and precision components.

Thermal and Flame Resistance Comparison of ULTEM®, PEEK, and Vespel®

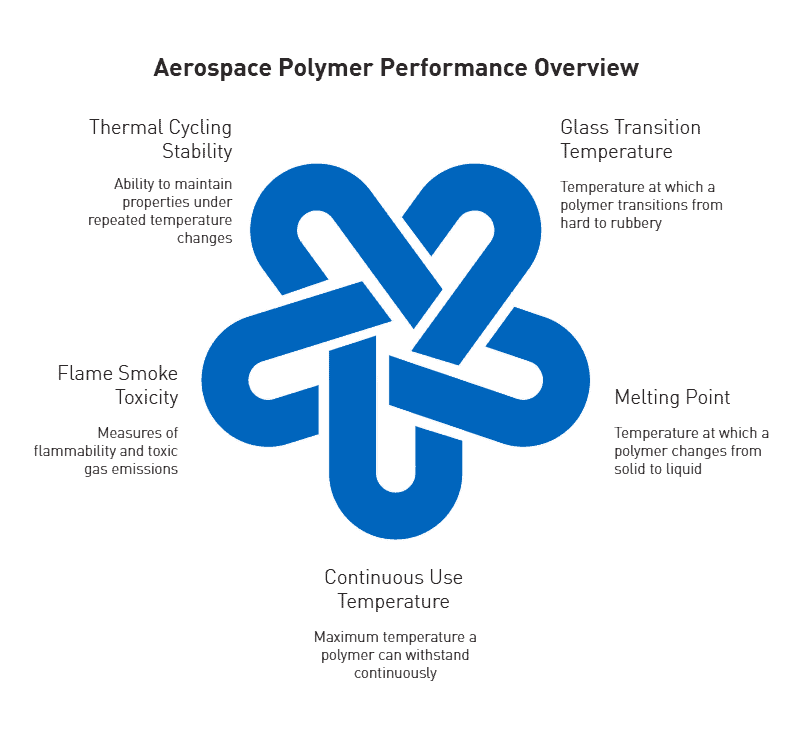

The thermal properties of aerospace polymers directly affect their performance in extreme conditions. Each material exhibits distinctive characteristics that determine its suitability for specific aerospace applications.

Glass Transition Temperature (Tg) and Melting Point (Tm) Benchmarks

The fundamental difference between these polymers lies in their molecular structure. ULTEM® is amorphous with a high glass transition temperature (Tg) of approximately 217°C (420°F). In contrast, PEEK is semi-crystalline with a lower Tg of around 143-150°C (289°F) but features a crystalline melting point of 343°C (649°F). This morphological difference explains why PEEK maintains structural integrity at temperatures exceeding its Tg. Vespel® polyimide completes the trio with exceptional thermal stability, allowing it to maintain performance across extreme temperature ranges.

Continuous Use Temperature: 500°F for PEEK vs 340°F for ULTEM®

Despite ULTEM®’s higher Tg, its continuous service temperature reaches only 340°F (171°C), primarily because amorphous regions soften above Tg. PEEK, however, can withstand continuous operating temperatures up to 500°F (260°C) because its crystalline regions remain stable above Tg. Vespel® surpasses both with continuous performance at temperatures up to 572°F (300°C), making it ideal for the most thermally demanding aerospace applications.

Flame Smoke Toxicity (FST) Ratings and FAA Compliance

Both ULTEM® and PEEK hold UL 94 V-0 flammability ratings. Additionally, ULTEM® achieves the more stringent 5VA rating at 1.6mm thickness and exhibits a higher Limiting Oxygen Index (LOI) of 47%. These properties ensure ULTEM® meets FAA 25.853 standards, particularly valuable for cabin interiors. For aerospace applications, materials must pass comprehensive Fire, Smoke, and Toxicity (FST) testing, including smoke density tests requiring values below 200 after burning for four minutes. Toxicity testing measures concentrations of critical gasses including carbon monoxide, hydrogen cyanide, and hydrogen chloride.

Thermal Cycling Stability in Aerospace Environments

Aerospace environments subject materials to repeated thermal cycling—from extreme cold at high altitudes to high heat during operation. Under such conditions, PEEK handles temperature variations from -55°C to +95°C without degradation. Notably, thermal cycling actually improves certain polymer properties; research shows that after multiple cycles, the glass transition temperature increases by 5-10°C and storage modulus rises significantly. ULTEM® 1000 maintains its toughness and impact resistance during temperature fluctuations, offering good dimensional stability in spacecraft applications.

Mechanical and Fatigue Performance Under Aerospace Loads

Structural integrity under mechanical stress represents a critical performance factor for aerospace polymers, especially when components face extreme operational conditions. Selecting the appropriate material requires thorough analysis of tensile strength, creep behavior, and fatigue resistance.

Tensile Strength: 16,000 psi (ULTEM®) vs 23,000 psi (Vespel®)

Tensile strength varies significantly among high-performance aerospace polymers. ULTEM® demonstrates a tensile strength of 15,200 psi (105 MPa) in its unfilled grade, which increases with glass-fiber reinforcement—reaching 17,000 psi in the 30% glass-filled ULTEM® 2300 variant. Vespel® polyimide excels with tensile strength reaching approximately 23,000 psi, making it suitable for highly stressed components. Torlon PAI positions between these two with 21,000 psi, establishing it as the strongest unreinforced thermoplastic available for industrial applications.

Impact Resistance and Creep Behavior in High-Stress Parts

Creep resistance—a material’s ability to resist deformation under constant stress—proves essential for aerospace components. Vespel® exhibits exceptional creep and stress relaxation behavior that outperforms virtually all other polymers, maintaining sealing force in high-pressure applications over extended periods. Essentially, polymers with higher crystallinity demonstrate lower creep rates. This characteristic makes semi-crystalline polymers like PEEK generally more creep-resistant than amorphous alternatives such as ULTEM®. Creep damage typically reaches maximum values (approximately 15% void fraction) in the tertiary stage of the creep process, with damage accelerating exponentially with increasing stress levels.

Fatigue Resistance in Repeated Load Cycles

Aerospace components routinely encounter cyclic loading that can lead to fatigue failure—often at stress levels well below ultimate tensile strength. High-cycle fatigue (HCF) testing simulates real-world operational conditions for components experiencing low stress and high-frequency cycles (typically above 10⁶ cycles). Conversely, low-cycle fatigue (LCF) evaluates performance under high stress and low-cycle loading (below 10⁵ cycles). Subsequently, PEEK demonstrates superior fatigue resistance compared to ULTEM®, particularly in dynamic environments subject to repeated stress.

Dimensional Stability in Precision Aerospace Parts

Precision aerospace applications demand exceptional dimensional stability across fluctuating environmental conditions. Torlon demonstrates excellent dimensional stability even at elevated temperatures, with a glass transition temperature of 280°C (536°F), allowing for consistent performance in precision applications. Consequently, high-performance polymers maintain tight tolerances in aircraft systems where precision directly impacts safety and performance.

Application Mapping: Where Each Polymer Excels in Aircraft Systems

Each aerospace polymer excels in specific aircraft applications based on its unique property profile.

PEEK in Flight Control and Engine Components

PEEK’s superior thermal resistance enables continuous operation at temperatures up to 500°F (260°C), making it ideal for engine casings, seals, and thrust washers. Flight control components, fuel system elements, and aerodynamic-related components frequently utilize PEEK primarily due to its exceptional strength-to-weight ratio. Accordingly, aircraft manufacturers achieve substantial weight savings—up to 60% when converting metallic components to PEEK.

ULTEM® in Cabin Interiors and Ventilation Systems

ULTEM® meets stringent FAA regulations for passenger safety. Throughout modern aircraft, this material appears in ventilation systems, personal service units, food service equipment, and oxygen delivery systems. Moreover, advanced cabin design specifications mandate ULTEM® integration throughout passenger interface systems. The Airbus A350 platform incorporates over 1,000 ULTEM®-based components, demonstrating successful aerospace qualification.

Vespel® in Vacuum Seals and High-Wear Bearings

For high-pressure spline connections transmitting power to aircraft systems, Vespel® polyimide couplings installed between mating metal splines ensure smoother operation. The polymer’s ductility allows shaft misalignment without creating excessive stress on metal components. Unlike standard thermoplastics, Vespel® exhibits no observable glass transition temperature or abrupt softening point. This enables continuous operation at 500°F with excursions to 900°F.

Precision Parts for Aircraft Interiors: Latches, Panels, and Connectors

High-performance polymers enable reliable performance in critical load-bearing applications, including precision-engineered latches, hinges, and access mechanisms. RADEL® PPSU meets aircraft flammability requirements per 14 CFR Part 25, providing engineers with material options that are lightweight, safe, and esthetically pleasing. This material offers exceptional toughness while meeting OSU 65/65 and FAR 25.853 standards.

Custom Precision Aerospace Parts for Fuel and Electrical Systems

PEEK’s chemical unreactivity allows it to withstand constant exposure to aviation fuels and hydraulic fluids without degradation. It’s extensively used in convoluted tubing protecting critical electrical systems. ULTEM®’s superior dielectric properties establish technical leadership in aircraft electrical systems, enabling reliable performance in power distribution infrastructure and electronic control systems.

Need material guidance? Our experts will help you match the right polymer to your spec. https://aipprecision.com/get-a-quote/

Machinability, Certifications, and AIP’s Aerospace Capabilities

Precision manufacturing of aerospace polymers requires specialized equipment and technical expertise beyond standard plastic machining capabilities. The process demands strict adherence to industry regulations while maintaining exceptional dimensional accuracy.

5-Axis CNC Machining for Aerospace Grade Plastics

Advanced 5-axis CNC technology enables manufacturers to create complex aerospace components with intricate geometries. This precision technology allows single-setup machining, thereby eliminating alignment errors between operations. Five-axis capabilities prove indispensable when producing components with compound angles, undercuts, or features requiring simultaneous multi-axis control.

AS9100D and ITAR Certification for Aerospace Compliance

Quality management systems certified to AS9100D standards ensure consistent production processes throughout the aerospace supply chain. Furthermore, International Traffic in Arms Regulations (ITAR) registration confirms a manufacturer’s compliance with export control requirements for defense-related parts. These certifications establish trust throughout the industry by verifying adherence to standardized quality protocols.

Post-Curing Requirements for Vespel® and Torlon®

After initial machining, Vespel® and Torlon® parts require thermal post-curing to achieve their final mechanical properties. This critical heat-treatment process stabilizes dimensions, releases internal stresses, and develops optimal material characteristics. The process often extends over several days through carefully controlled temperature staging.

Tolerances and Surface Finish in Precision Plastic Machining

High-performance thermoplastics can maintain tolerances as tight as ±0.001″ with proper machining protocols. Surface finish specifications typically range from 16-64 RMS depending on application requirements. Machining strategies must account for material-specific thermal expansion characteristics.

AIP’s Experience with High-Performance Thermoplastics

AIP Precision Machining specializes in producing complex aerospace polymer components through validated manufacturing processes. Their expertise includes material selection consulting, design optimization, and quality assurance throughout production.

Conclusion

High-performance aerospace polymers—PEEK, ULTEM®, and Vespel®—have proven themselves across critical performance metrics including thermal stability, mechanical strength, and regulatory compliance.

PEEK offers the best balance of continuous thermal resistance (up to 500°F) and fatigue performance, making it ideal for engine components, flight control systems, and fuel-handling parts. ULTEM® delivers superior flame-smoke-toxicity compliance, meeting FAA 25.853 standards for cabin interiors and electrical systems. Vespel® stands out for exceptional creep resistance and dimensional stability in extreme thermal and pressure environments, such as high-wear seals and precision bearings.

Ultimately, the right material depends on application-specific demands—whether it’s sustained thermal load, exposure to aggressive fluids, or the need for ultra-tight tolerances in dynamic systems.

Combined with advanced 5-axis CNC machining, post-curing expertise, and AS9100D-certified processes, these polymers enable significant weight reduction, increased design flexibility, and extended component lifespan across commercial and defense aerospace platforms.

AIP Precision Machining supports engineers and sourcing leaders with material selection, design optimization, and precision manufacturing strategies tailored to your exact aerospace requirements.

FAQs

Q1. What are the key differences between ULTEM®, PEEK, and Vespel® in aerospace applications?

ULTEM® excels in flame resistance and is ideal for cabin interiors, PEEK offers superior thermal and chemical resistance for engine components, while Vespel® provides exceptional dimensional stability and creep resistance for high-pressure seals and bearings.

Q2. How do these aerospace polymers compare in terms of continuous use temperature?

PEEK can withstand continuous operating temperatures up to 500°F (260°C), ULTEM® reaches 340°F (171°C), and Vespel® surpasses both with performance at temperatures up to 572°F (300°C).

Q3. What are the weight reduction benefits of using these polymers in aircraft?

High-performance aerospace polymers can reduce component weight by up to 50% compared to traditional metal parts, significantly improving fuel efficiency and lowering operational costs.

Q4. How do these materials perform in terms of flame resistance for aerospace applications?

Both ULTEM® and PEEK hold UL 94 V-0 flammability ratings, with ULTEM® achieving the more stringent 5VA rating and meeting FAA 25.853 standards, making it particularly valuable for cabin interiors.

Q5. What manufacturing processes are used for creating aerospace components from these polymers?

Advanced 5-axis CNC machining technology is used to create complex aerospace components with intricate geometries. Some materials like Vespel® and Torlon® require thermal post-curing to achieve their final mechanical properties.