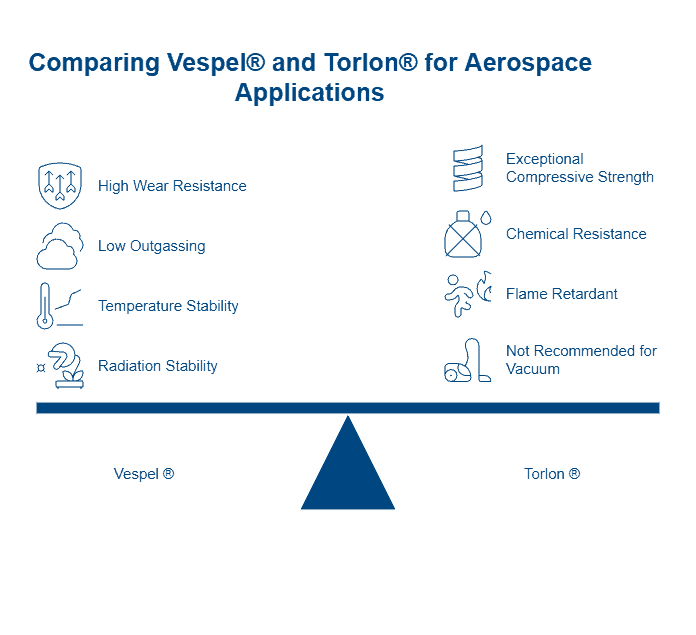

When aerospace applications demand exceptional performance under extreme conditions, engineers often find themselves choosing between two elite high-performance thermoplastics: Vespel® and Torlon®.

While Vespel® offers excellent thermal stability (Vespel® has the ability to maintain strength at temperatures up to 550 degrees Fahrenheit and withstand brief exposures to 900 degrees), chemical resistance, and dielectric strength, Torlon® provides even greater mechanical properties and load-bearing capabilities. In fact, both materials have carved out specialized roles in critical aerospace components, with Vespel® commonly used in electrical insulation and high-temperature bearings, while Torlon® excels in applications requiring exceptional stiffness and dimensional stability under heavy loads. The difference between these materials can significantly impact performance, reliability, and longevity of critical flight systems.

This article will examine the key distinctions between these remarkable polymers to help you determine which material best suits your aerospace application requirements.

Material Properties: Vespel® vs Torlon® at the Molecular Level

At the molecular level, Vespel® and Torlon® exhibit distinct chemical structures that directly influence their performance characteristics in aerospace applications.

Polyimide vs Polyamide-Imide Structure

Vespel® material consists of a polyimide (PI) composition with imide linkages that create exceptional thermal stability. Meanwhile, Torlon® is a polyamide-imide (PAI) thermoplastic, containing both amide and imide linkages alternating in its polymer chain. This molecular difference is fundamental – PAI combines the mechanical strength of polyamides with the thermal stability of polyimides, resulting in a hybrid material with unique properties.

Thermal Resistance: 550°F vs 500°F Continuous Use

Though closely matched, Vespel® demonstrates slightly superior thermal performance with continuous service temperatures up to 550°F (288°C). Consequently, it maintains structural integrity from cryogenic conditions to extreme heat. Torlon® offers impressive thermal resistance as well, with continuous use temperatures up to 500°F (260°C). Furthermore, Vespel® has no observable glass transition temperature below its decomposition point, which exceeds 752°F (400°C).

Moisture Absorption and Chemical Resistance

One notable difference between these materials appears in their moisture absorption characteristics. Torlon® exhibits a relatively higher moisture absorption rate compared to Vespel®. Nevertheless, both materials demonstrate exceptional resistance to chemicals, including acids, bases, and solvents. Torlon® particularly excels in resistance to aliphatic, aromatic, chlorinated, and fluorinated hydrocarbons.

Dielectric Strength and Electrical Insulation

Vespel® shows remarkable dielectric properties, with SP-1 grade offering 560 V/mil dielectric strength. Additionally, it maintains excellent electrical insulation even at high temperatures, making it particularly valuable for electronic aerospace assemblies.

Mechanical Strength: Tensile and Flexural Ratings

The mechanical properties of these materials reveal interesting contrasts. Torlon® 4435 demonstrates a tensile strength of 107 MPa (15.5 ksi), substantially higher than Vespel® SP-21’s 62 MPa (9.0 ksi). Similarly, Torlon®’s flexural modulus reaches 15.2 GPa (2.2 Msi), vastly exceeding Vespel® SP-21’s 3.2 GPa (0.5 Msi). However, Vespel® maintains its performance more consistently under extreme temperature variations.

Aerospace Applications: Where Each Material Excels

Beyond their molecular differences, Vespel® and Torlon® each shine in specific aerospace applications based on their unique performance attributes.

Vespel® Material Uses in Aerospace Bearings and Seals

Since 1965, Vespel® has outperformed other engineering materials under extreme conditions. Its combination of low wear, low friction, and impressive strength makes it ideal for aircraft engine bearings, bushings, washers, and seal rings. Notably, Vespel® SP-21 thrust bearings survive pressure-velocity conditions as high as 400,000 psi-ft/min. Moreover, Vespel® has proven especially effective in aircraft fan blade wear strips and blade spacers where strength and wear resistance are crucial. For spline couplings connecting metallic shafts, Vespel®’s elastic deformation properties redistribute loads more evenly, resulting in longer wear life.

Torlon® Properties in Aerospace Pump Housings and Valves

Torlon® sets benchmarks for reliability in aerospace components that require exceptional compressive strength. Specifically, aerospace bearings and bushings constructed from Torlon® maintain strict tolerance adherence under loads exceeding what traditional plastics can handle. Torlon®’s chemical resistance allows it to tolerate extended contact with phosphate ester fluids, jet fuels, hydraulic oils, and cleaning agents without swelling or cracking. This makes it particularly suitable for fluid management components, seals, manifold blocks, and check valves. Besides its strength, Torlon®’s flame-retardant qualities restrict combustion and suppress flame spread, even during direct exposure to ignition sources.

Performance in Cryogenic and Vacuum Environments

Vespel® maintains properties from cryogenic to high temperatures with exceptional dimensional stability. Essentially, Vespel® functions effectively in vacuum environments where it has replaced ceramic seals and gaskets in ultra-high vacuum conditions. According to the ASTM E595 standard developed by NASA, Vespel® exhibits low outgassing under vacuum. Conversely, Torlon® is not recommended for vacuum applications as it will “out-gas” and contaminate the environment.

Radiation and Outgassing Considerations

Radiation exposure tests show Torlon®-4203 samples experienced approximately 60 times higher wear compared to Vespel® SCP-5050 after high radiation exposure (10 Mrad). Indeed, Vespel® parts demonstrate excellent radiation stability with coefficient of friction, wear properties, and mechanical properties remaining nearly unchanged after exposure.

Tolerances for Aerospace Polymers

Precision engineering demands exacting standards for aerospace components, with tolerance capabilities directly influencing flight safety and performance. High-performance thermoplastics can maintain tolerances as tight as ±0.001″ when machined properly.

For optimal dimensional stability with Vespel® material, components should be rough-machined to within 0.015-0.020 inch of finished size, then equilibrated at 70°F and 50% relative humidity before final machining. Vespel®’s low and consistent thermal expansion coefficient allows for tight dimensional tolerances across various applications.

Remarkably, Torlon® maintains structural integrity even under extreme conditions. Despite rapid pressure fluctuations common in airframes, Torlon® consistently preserves its geometry without micro-cracking or creep. Its polyamide-imide structure effectively blocks heat-induced relaxation under load, thus preserving critical dimensions throughout entire mission timelines.

Surface finish specifications typically range from 16-64 RMS depending on application requirements. Machining strategies must account for material-specific thermal expansion characteristics to achieve precision results.

For difficult features like deep blind holes, special attention is required as these are challenging to manufacture to close tolerances. The depth of feed should not exceed 0.005 inch on first pass, gradually reducing to 0.002 inch per pass until completion. For extremely precise applications, parts may need machining and measuring in controlled environments.

Choosing the Right Material for Your Project

Selecting between Vespel® and Torlon® requires balancing specific performance needs against application constraints. Making this critical decision often depends on four key factors.

Torlon® vs Vespel® Wear Resistance in Moving Parts

Regarding wear resistance, both materials excel in different scenarios. Vespel® features excellent friction and wear characteristics, performing remarkably in high-wear applications without lubrication. Alternatively, Torlon® demonstrates exceptional toughness with superior mechanical resistance to high impacts and stress, providing dimensional stability that prevents premature wear. For bearings and high-motion components, Vespel® can withstand pressure-velocity conditions as high as 400,000 psi-ft/min.

Vespel® Thermal Stability in High-Heat Zones

Vespel® demonstrates superior thermal performance with continuous service temperatures up to 550°F, compared to Torlon®’s 500°F. Uniquely, Vespel® exhibits no observable glass transition temperature or abrupt softening point. Actually, Vespel® doesn’t melt at any temperature, allowing short-term exposure to temperatures as high as 900°F. NASA even selected Vespel® SP-211 for components exposed to temperatures reaching 750°F.

Cost, Availability, and Processing Time

Vespel® ranks among the most expensive engineering materials available. Although costly initially, both materials typically offer lower lifetime costs than specially treated metal components. Yet Torlon® presents machining challenges, requiring specialized tooling due to its extreme hardness.

Decision Matrix Based on Application Needs

Altogether, your selection should consider:

- Vacuum requirements: Vespel® won’t outgas; Torlon® will contaminate vacuum environments

- Moisture exposure: Vespel® has lower absorption

- Mechanical needs: Torlon® for strength; Vespel® for wear resistance

Comparison Table

| Property/Characteristic | Vespel® | Torlon® |

| Thermal Properties | ||

| Continuous Use Temperature | 550°F (288°C) | 500°F (260°C) |

| Brief Temperature Exposure | Up to 900°F | Not mentioned |

| Glass Transition | No observable point below decomposition | Not mentioned |

| Mechanical Properties | ||

| Tensile Strength | 62 MPa (9.0 ksi) [SP-21] | 107 MPa (15.5 ksi) [4435] |

| Flexural Modulus | 3.2 GPa (0.5 Msi) [SP-21] | 15.2 GPa (2.2 Msi) |

| Chemical/Environmental Properties | ||

| Moisture Absorption | Lower absorption rate | Higher absorption rate |

| Chemical Resistance | Excellent resistance to chemicals | Excellent resistance, especially to hydrocarbons |

| Vacuum Performance | Low outgassing, suitable for vacuum | Not recommended, will outgas |

| Electrical Properties | ||

| Dielectric Strength | 560 V/mil [SP-1] | Not mentioned |

| Application Strengths | ||

| Primary Applications | – Electrical insulation – High-temperature bearings – Fan blade wear strips – Spline couplings |

– Pump housings – Valves – Heavy load applications – Fluid management components |

| Performance Under Conditions | ||

| Radiation Resistance | Excellent stability, properties remain unchanged | Higher wear rate (60x more than Vespel® after exposure) |

| Load-Bearing | Good | Superior mechanical properties |

| Dimensional Stability | Excellent across temperature ranges | Excellent under heavy loads |

Conclusion

Selecting the right high-performance polymer is a mission-critical decision in aerospace engineering. Vespel® and Torlon® each offer distinct advantages that can dramatically influence part longevity, system performance, and compliance with aerospace operating environments.

For applications exposed to extreme heat, radiation, or vacuum, Vespel® is unmatched in its thermal endurance, dielectric strength, and low outgassing behavior. Conversely, for components under continuous mechanical stress, pressure, and fluid exposure, Torlon® provides the strength and dimensional stability required to maintain integrity under demanding conditions.

At AIP Precision Machining, we partner directly with aerospace engineers and procurement leaders to guide material selection, prototyping, and ultra-precision machining of Vespel®, Torlon®, and other mission-critical polymers. With AS9100D and ISO 9001 certifications, our team ensures every component meets the strictest aerospace standards from initial design through final inspection.

Need help deciding between Vespel® and Torlon® for your next aerospace application?

Partner with the polymer machining experts at AIP Precision. Our engineering team provides:

- – Application-specific material consulting

- – DFM support for weight, tolerance, and thermal optimization

- – Ultra-precision machining down to ±0.002 mm

- – Certified compliance with AS9100D, ISO 9001, and ITAR

Request a consultation today or get a custom quote: aipprecision.com/get-a-quote

FAQs

Q1. What are the main differences between Vespel® and Torlon® in aerospace applications?

Vespel® excels in thermal stability, with continuous use temperatures up to 550°F and brief exposures to 900°F. It’s ideal for high-temperature bearings and electrical insulation. Torlon®, on the other hand, offers superior mechanical strength and is better suited for heavy load applications like pump housings and valves, with continuous use temperatures up to 500°F.

Q2. How do Vespel® and Torlon® compare in terms of wear resistance?

Both materials offer excellent wear resistance, but in different scenarios. Vespel® performs remarkably in high-wear applications without lubrication, especially in bearings and high-motion components. Torlon® demonstrates exceptional toughness and superior mechanical resistance to high impacts and stress, providing dimensional stability that prevents premature wear.

Q3. Which material is better suited for vacuum environments?

Vespel® is the preferred choice for vacuum environments. It exhibits low outgassing properties and maintains its performance in ultra-high vacuum conditions. Torlon®, however, is not recommended for vacuum applications as it tends to outgas and can contaminate the environment.

Q4. How do these materials perform under radiation exposure?

Vespel® demonstrates excellent radiation stability, with its properties remaining nearly unchanged after exposure. In contrast, Torlon® samples have shown significantly higher wear rates (approximately 60 times higher) compared to Vespel® after high radiation exposure.

Q5. What are the cost considerations when choosing between Vespel® and Torlon®?

Vespel® is generally more expensive initially compared to other engineering materials. However, both Vespel® and Torlon® typically offer lower lifetime costs than specially treated metal components when used in appropriate applications. The choice between them should consider specific performance needs against application constraints and long-term cost-effectiveness.