ULTEM® aerospace parts play a vital role in the industry because of their exceptional performance characteristics. ULTEM® stands out as one of the few resins with approval for aerospace applications. This 30-year old material powers flight-critical components. Our team at AIP Precision Machining has supplied ULTEM® components to aircraft OEM and MRO providers of all sizes worldwide.

Engineers and procurement specialists need to know the differences between ULTEM® 1000 and ULTEM® 2300 for aerospace applications. ULTEM® 1000, the standard unfilled polyetherimide product, shows impressive strength that goes beyond 1300MPa at room temperature. ULTEM® 2300, with its 30% glass fiber reinforcement, reaches around 2100MPa. The material’s heat distortion temperature sits at 204°C at 264 psi. This makes it perfect for high-temperature aerospace environments. The material stays strong under repeated mechanical stress and meets FAA’s strict flammability regulations.

Key Takeaways

Understanding the critical differences between Ultem® 1000 and 2300 enables aerospace engineers to make informed material selections for mission-critical components based on specific performance requirements.

• Ultem® 1000 excels in electrical applications with superior dielectric strength (830 V/mil) and transparency, making it ideal for avionics housings and electrical insulators.

• Ultem® 2300 provides superior structural performance with 30% glass reinforcement delivering 850,000 psi flexural modulus versus 500,000 psi for Ultem® 1000.

• Thermal expansion differs significantly – Ultem® 2300’s coefficient (1.1 x 10^-5 in/in/°F) matches aluminum, while Ultem® 1000 expands nearly 3x more.

• Machining requirements vary between grades – Ultem® 1000 offers easier machinability, while glass-filled Ultem® 2300 requires specialized tooling and lower speeds.

• Both materials meet stringent aerospace standards including FAA flammability regulations, low outgassing for space applications, and resistance to aviation fluids.

The key decision factor: Choose Ultem® 1000 for electrical insulation and weight-sensitive applications, select Ultem® 2300 for structural components requiring maximum rigidity and dimensional stability under load.

Ultem® 1000 and 2300: Material Overview and Composition

Polyetherimide (PEI), sold under the Ultem® trademark, stands as a breakthrough in high-performance engineering thermoplastics. General Electric introduced this remarkable material in 1982, and it quickly became essential for aerospace applications that need top-notch thermal stability and mechanical strength.

Ultem® 1000: Unfilled PEI for General Aerospace Use

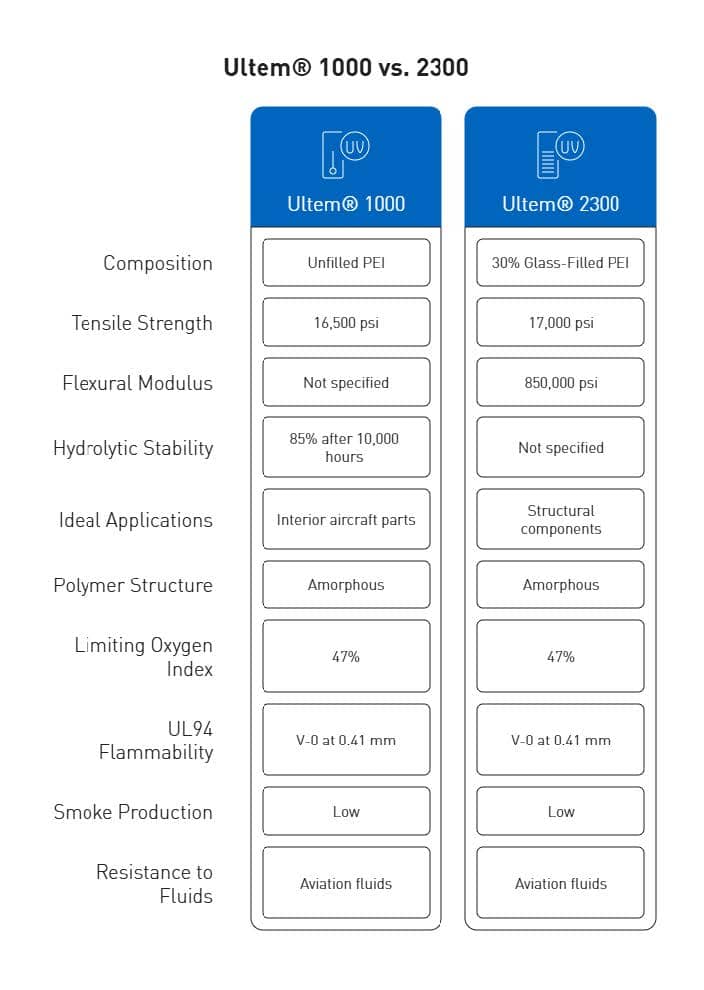

Ultem® 1000 serves as the standard unfilled grade of polyetherimide – you can call it the “virgin” or “neat” resin without additives. This amber-colored, transparent thermoplastic shows impressive mechanical strength that tops 16,500 psi. The material’s excellent hydrolytic stability helps it keep 85% of tensile strength even after 10,000 hours in boiling water. Ultem® 1000 works best where flame resistance, electrical insulation, and chemical stability matter most, making it perfect for interior aircraft parts.

Ultem® 2300: 30% Glass-Filled PEI for High-Rigidity Applications

Ultem® 2300 takes things further by adding 30% glass fiber reinforcement to boost its mechanical properties. This addition lifts tensile strength to about 17,000 psi and flexural modulus to 850,000 psi, which means better dimensional stability than Ultem® 1000. Ultem® 2300’s ability to handle high tensile loads makes it ideal for structural components that face serious mechanical stress in aerospace applications.

Ultem® Polymer Structure and Amorphous Behavior

PEI’s repeating unit has a molecular formula of C₃₇H₂₄O₆N₂ with a molecular weight of 592.61 g/mol. Ultem® differs from semi-crystalline polymers because it’s completely amorphous and contains phthalimide and bisphenol A sub-units. This amorphous structure creates isotropic behavior and reliable dimensional stability across different temperatures. The material’s glass transition temperature reaches 217°C (421°F), which explains its great mechanical properties at high temperatures.

Ultem® Material Properties Relevant to Aerospace

Aerospace engineers value Ultem®’s mix of high strength-to-weight ratio and thermal stability. Both grades deliver outstanding flame resistance with a limiting oxygen index of 47% and meet UL94 V-0 specifications in sections as thin as 0.41 mm. The materials produce very little smoke during combustion, which is crucial for aircraft interior safety. Ultem® also resists aviation fluids well, including jet fuel and hydraulic fluids, and stays strong in these tough operating conditions.

Side-by-Side Performance Metrics for Aerospace Engineers

Aerospace engineers need reliable data to pick the right materials for flight-critical components. Here is a side by side comparison of Ultem® 1000 and 2300:

| Performance Category | Ultem® 1000 (Unfilled PEI) | Ultem® 2300 (30% Glass-Filled PEI) |

| Tensile Strength | 16,500 psi | 17,000 psi |

| Flexural Modulus | 500,000 psi | 850,000 psi |

| Thermal Expansion | 3.1 × 10⁻⁵ in/in/°F | 1.1 × 10⁻⁵ in/in/°F (similar to 6061-T6 aluminum) |

| Heat Deflection Temp (264 psi) | 400°F (204°C) | 410°F (210°C) |

| Dielectric Strength | 830 V/mil (higher electrical insulation) | 770 V/mil |

| Surface Resistivity | > 10¹³ ohms/square | > 10¹³ ohms/square |

| Weight Considerations | Lower density; ideal for lightweight applications | Heavier; optimized for strength and rigidity |

| Machinability | Easier to machine; less tool wear | More abrasive; requires specialized tooling |

| Ideal Aerospace Use Cases | Avionics housings, electrical insulators, covers | Structural brackets, load-bearing components |

Tensile Strength and Flexural Modulus Comparison

The tensile strength numbers tell an interesting story. Ultem® 1000 delivers 16,500 psi, and Ultem® 2300 comes in at 17,000 psi. This small difference matters a lot for parts under heavy loads. The flexural modulus shows an even bigger gap – Ultem® 1000 reaches 500,000 psi while Ultem® 2300 hits 850,000 psi. Glass-reinforced Ultem® 2300 proves much better for structural parts that need to resist bending forces.

Thermal Expansion and Heat Deflection Differences

Let’s look at how these materials handle heat. Ultem® 1000’s coefficient of linear thermal expansion is 3.1 x 10^-5 in/in/°F, while Ultem® 2300 comes in at 1.1 x 10^-5 in/in/°F. Ultem® 2300’s thermal expansion matches 6061-T6 aluminum closely, making it perfect for replacing metal parts. The heat deflection temperature at 264 psi shows Ultem® 1000 stays stable up to 400°F (204°C). Ultem® 2300 edges slightly ahead at 410°F (210°C).

Electrical Insulation and Dielectric Strength

Both materials excel at electrical insulation. Ultem® 1000 leads the pack with one of the highest dielectric strengths among thermoplastics at 830 V/mil. Ultem® 2300 follows closely at 770 V/mil. Both materials show surface resistivity above 10^13 ohms/square, which means excellent insulation properties at any frequency.

Weight vs Strength Tradeoffs in Ultem® 1000 Aerospace Parts

Ultem® 2300 might have better mechanical properties, but Ultem® 1000 shines in aerospace applications where weight matters most. Ultem® 1000 matches the strength of filled thermoplastics and adds transparency as a bonus. Its molecular chain flexibility helps absorb impact energy without breaking. This feature proves crucial for parts that might take occasional hits.

CNC Machining Considerations for Ultem® 1000 vs 2300

At AIP Precision, our polymer-exclusive facility specializes in machining Ultem® materials for aerospace applications. Our specialized techniques achieve the highest precision levels. The contamination-free processing we provide will give a solid foundation for flight-critical components.

Chip Formation and Toolpath Optimization

Ultem® creates long, thin chips during machining that might clog cutting tools without proper management. Our team uses tools with high rake angles and optimized chipbreakers to promote quick chip evacuation for Ultem® 1000. High helix end mills work best with Ultem® 2300 because its glass reinforcement produces more abrasive chips that need better management. The team must remove scrap continuously to prevent surface scratches and internal stresses.

Machining-Induced Stress and Warpage

Stress-relieving through annealing helps prepare Ultem® materials before machining. This step reduces surface cracks and internal stresses. Our process for Ultem® 2300 includes post-machining annealing at 300°F to 400°F (150°C to 200°C) for several hours. The material cools slowly afterward. These steps stabilize material dimensions and relieve machining-induced stresses.

Surface Finish Quality in Tight-Tolerance Parts

Tool selection affects surface quality heavily in aerospace components that need precise tolerances. Both grades require sharp carbide tools because of Ultem®’s abrasive nature. Our team switches to a “polishing knife” during the final 0.1mm light cutting process for Ultem® 2300. This approach helps us control surface roughness within Ra < 1.6 μm and meet aerospace industry standards.

Material Removal Rate and Feed Rate Adjustments

Each material needs different cutting parameters. Ultem® 1000 works best at speeds of 800-1200 rpm. Glass-reinforced Ultem® 2300 needs lower speeds of 600-1000 rpm to prevent thermal expansion. Feed rates should stay between 0.05-0.12 mm/rev. Light cuts of 0.3-0.5mm during finishing help maintain geometric accuracy.

AIP brings over 40 years of experience in machining advanced polymers exclusively. We help aerospace teams reduce risk, speed up timelines, and ensure compliance. Our AS9100-certified machining of Ultem® 1000 or Ultem® 2300 delivers high-performance aerospace components with tight tolerances. Contact us today to review your design or request a precision quote.

When to Choose Ultem® 1000 or 2300 for Aerospace Applications

Choosing between Ultem® 1000 and 2300 depends on your aerospace application’s specific needs.

Avionics Housings and Electrical Insulators

Avionics housings and electrical components benefit from Ultem® 1000’s exceptional dielectric strength of 830 V/mil, which makes it the top choice. Ultem® 1000’s volume resistivity is a big deal as it means that it exceeds 10^13 ohms/square, delivering superior electrical insulation across wide frequency ranges. The unfilled Ultem® 1000 stands out when applications need low electrical conductivity and UV radiation resistance. This makes it perfect for sensor housings, electrical connectors, and circuit board components.

Thermal Insulators and Fluid System Components

Ultem® 1000 retains 85% of its tensile strength after 10,000 hours in boiling water, which proves excellent for fluid system components. Notwithstanding that, Ultem® 2300 shows better results in high-temperature fluid systems with its higher heat deflection temperature of 410°F (210°C).

Both materials resist aviation fluids effectively and maintain their structural integrity in fuel systems.

Structural Brackets and Load-Bearing Supports

Ultem® 2300’s 30% glass fiber reinforcement delivers a tensile strength of approximately 2100MPa compared to Ultem® 1000’s 1300MPa. Structural brackets under mechanical stress benefit from Ultem® 2300’s enhanced rigidity. This becomes clear in its flexural modulus of 850,000 psi versus Ultem® 1000’s 500,000 psi. Ultem® 2300 can replace aluminum in structural applications because its thermal expansion coefficient matches 6061-T6 aluminum.

Ultem® Space Applications: Outgassing and Stability

These grades show low outgassing properties, and Ultem® 9085 (a variant) shows remarkably low CVCM values of 0-0.1%. Space applications benefit from Ultem® because outgassing could contaminate sensitive optics or electronics. The material works well in orbital applications due to its dimensional stability under extreme temperature changes.

Precision Plastics Machining for Mission-Critical Parts

Precision-machined components work better with Ultem® 1000 as it causes less tool wear. Ultem® 2300 needs specialized tooling because of its glass fiber abrasiveness.

Conclusion

This piece explores the key differences between Ultem® 1000 and Ultem® 2300 for aerospace applications. These high-performance polymers are a great way to get the right properties for flight-critical components, each with distinct advantages for specific uses.

Ultem® 1000’s unfilled PEI composition delivers superior electrical insulation, making it perfect for avionics housings and components that need excellent dielectric strength. It also offers transparency, impact resistance, and better machinability – clear advantages for many aerospace applications.

The glass fiber reinforcement in Ultem® 2300 makes it excel in structural applications. This boost increases flexural modulus and tensile strength by a lot while bringing thermal expansion down to aluminum-like levels. Aerospace engineers should pick this variant when designing load-bearing brackets and components under mechanical stress.

Both materials showcase remarkable thermal stability, chemical resistance, and flame retardancy – vital properties in aerospace environments. Your specific application needs will determine the choice between these exceptional polymers, whether you need electrical insulation or structural support, lighter weight or maximum rigidity.

AIP Precision’s four decades of experience have taught us these subtle differences through machining these advanced polymers to aerospace specifications. Our polymer-exclusive facility will give a contamination-free processing environment with ±0.002 mm tolerances under AS9100 certification. We use specialized techniques like optimized toolpaths and post-machining annealing to deliver top-quality Ultem® components.

As someone who works closely with aerospace engineers and sourcing managers every day, I’ve seen firsthand how the right material selection impacts long-term performance and program success. Whether you’re deciding between Ultem® 1000 for its electrical insulation or Ultem® 2300 for structural reinforcement, AIP can support your team from concept to final part. If you have questions about which Ultem® grade is right for your aerospace application, feel free to reach out. — Fred Castro, Project Specialist, AIP Precision Machining.

FAQs

Q1. What are the main differences between Ultem® 1000 and Ultem® 2300?

Ultem® 1000 is an unfilled polyetherimide (PEI) with superior electrical properties, while Ultem® 2300 contains 30% glass fiber reinforcement for enhanced mechanical strength. Ultem® 1000 excels in electrical insulation, while Ultem® 2300 is better suited for structural applications requiring high rigidity.

Q2. Which Ultem® grade is better for aerospace structural components?

Ultem® 2300 is generally preferred for aerospace structural components due to its higher flexural modulus (850,000 psi) and tensile strength. Its glass fiber reinforcement provides greater rigidity and dimensional stability under mechanical stress, making it ideal for load-bearing brackets and supports.

Q3. How do Ultem® 1000 and 2300 compare in terms of thermal properties?

Both materials offer excellent thermal stability, but Ultem® 2300 has a slightly higher heat deflection temperature (410°F/210°C) compared to Ultem® 1000 (400°F/204°C). Notably, Ultem® 2300’s thermal expansion coefficient is closer to that of aluminum, making it suitable for metal replacement in certain applications.

Q4. Are there any machining differences between Ultem® 1000 and 2300?

Yes, there are significant machining differences. Ultem® 1000 is generally easier to machine with less tool wear. Ultem® 2300, due to its glass fiber content, requires specialized tooling and lower machining speeds to manage the abrasiveness of the material and maintain surface quality.

Q5. How do these materials perform in terms of flame resistance and chemical stability?

Both Ultem® 1000 and 2300 exhibit excellent flame resistance, meeting UL94 V-0 specifications and FAA flammability regulations. They also demonstrate high chemical stability, maintaining integrity when exposed to aviation fluids, including fuel and hydraulic fluids, making them suitable for various aerospace applications.