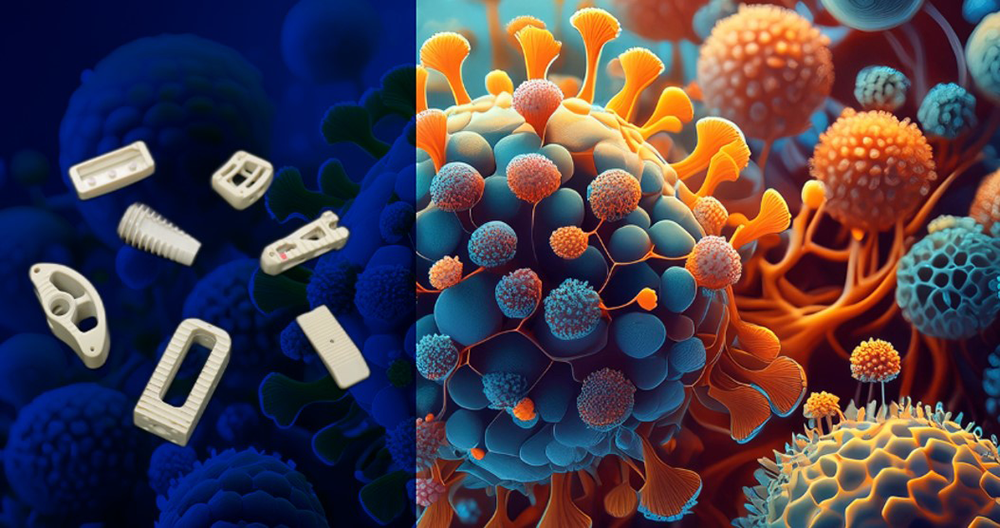

In recent years, the use of PEEK implants in medical applications has gained significant attention due to their unique properties and potential to minimize infection risks. AIP Precision Machining specializes in crafting highly precise PEEK components, ensuring the highest standards of quality and performance in critical medical applications.

PEEK, or polyetheretherketone, is a high-performance polymer that exhibits excellent biocompatibility, making it an ideal material for orthopedic implants and other medical devices. As healthcare providers strive to reduce complications associated with implant-related infections, understanding the role of PEEK in mitigating these risks has become increasingly important.

This article explores the benefits of using PEEK materials in medical implants and how their inherent properties contribute to reducing infection risks. It discusses the current challenges associated with implant-related infections, which can lead to serious complications for patients, and emphasizes the importance of utilizing materials that possess antibacterial properties. The article also details the specific characteristics of PEEK, such as its resistance to biofilm formation and its ability to be machined into precise peek parts, making it a game-changing material in the field of medical implants.

Understanding the Advantages of Using PEEK in Medical Implants

PEEK (polyetheretherketone) is a high-performance polymer and a member of the polyaryletherketone family, known for their excellent mechanical and chemical resistance due to their molecular structure consisting of phenylene rings and oxygen bridges. This chemical composition imparts PEEK with resilience, durability, and strength, making it an attractive material for orthopedic and spinal implants.

One of the key advantages of PEEK as a biomaterial is its biocompatibility. PEEK has been proven safe for in vivo applications, showing no signs of cytotoxicity, genotoxicity, or immunogenicity. It has been successfully used in medical implants for over 20 years. Compared to traditional metallic implant materials like titanium and stainless steel, PEEK has a more favorable flexural modulus that closely matches that of human bone. This similarity in flexibility helps reduce stress shielding and promotes better load transfer to the surrounding bone tissue.

Another significant benefit of PEEK implants is their radiolucency. Unlike metal implants which are radiopaque, PEEK is transparent on X-rays, CT, and MRI scans. This property allows surgeons to easily track the positioning of the implant and detect any complications post-operatively without interference from the implant material itself. The radiolucency of PEEK also enables the use of lower radiation doses during imaging, reducing patient exposure.

PEEK Composition and Benefits

PEEK is a thermoplastic polymer consisting of an aromatic backbone molecular chain interconnected by ketone and ether functional groups. This chemical structure provides PEEK with:

- High thermal stability (melting point around 343°C)

- Excellent chemical and radiation resistance

- Mechanical strength superior to many metals on a per-mass basis

- Compatibility with reinforcing agents like carbon and glass fibers

The biocompatibility, favorable modulus, and radiolucency of PEEK have positioned it as a leading biomaterial candidate for replacing metallic components in load-bearing orthopedic and spinal implants. Its ability to be sterilized using standard methods like gamma and electron beam radiation without degradation is another key advantage for medical applications. AIP Precision Machining utilizes advanced techniques such as 5-axis and 7-axis machining to fabricate PEEK parts with intricate designs and tight tolerances, ensuring both performance and reliability in medical implants.

The Risk of Infections in Medical Implants

Medical implants, while designed to improve patient health and quality of life, carry an inherent risk of infection. Implant-related infections can lead to serious complications, prolonged hospital stays, and even life-threatening conditions. Understanding the common pathogens involved and the potential consequences of these infections is crucial for healthcare professionals and patients alike.

Common Pathogens and Infection Pathways

Common Pathogens and Infection Pathways

Implant-related infections are primarily caused by bacterial pathogens, with Staphylococcus aureus and Staphylococcus epidermidis being the most prevalent culprits. These bacteria can enter the body during the surgical procedure or through the bloodstream, adhering to the implant surface and forming biofilms. Biofilms are complex communities of microorganisms that secrete a protective extracellular matrix, making them highly resistant to antibiotics and the body’s immune defenses.

Other pathogens associated with implant infections include:

- Pseudomonas aeruginosa

- Escherichia coli

- Klebsiella pneumoniae

- Enterococcus species

- Candida species (fungal)

Infection pathways can be classified as:

- Perioperative: Inoculation of microorganisms during surgery or immediately after

- Hematogenous: Spread through blood or lymph from a distant infection site

- Contiguous: Spread from an adjacent infection focus (e.g., pre-existing osteomyelitis)

Consequences of Infections

Implant-related infections can have devastating consequences for patients, leading to:

- Chronic pain and discomfort

- Implant loosening or failure

- Tissue damage and necrosis

- Sepsis and systemic inflammatory response syndrome (SIRS)

- Increased morbidity and mortality

Treatment often involves prolonged antibiotic therapy, multiple surgical interventions, and even implant removal. This places a significant burden on patients, both physically and emotionally, and can result in substantial healthcare costs.

The importance of reducing infection risk in medical implants cannot be overstated. Implementing strict infection control measures, utilizing advanced materials like PEEK that minimize bacterial adhesion, and developing novel antimicrobial strategies are essential steps in combating this critical issue. By prioritizing infection prevention, healthcare providers can improve patient outcomes, reduce complications, and enhance the overall success of implant procedures.

PEEK: A Game-Changing Material

PEEK has emerged as a game-changing material in the field of medical implants, offering unique properties that address the limitations of traditional implant materials. Its excellent biocompatibility, mechanical strength, and radiolucency make it an attractive alternative to metals and ceramics.

PEEK vs Traditional Implant Materials

PEEK offers several advantages over traditional implant materials such as titanium and stainless steel:

- Lower elastic modulus: PEEK’s elastic modulus is closer to that of human bone, reducing stress shielding and promoting better load transfer to the surrounding bone tissue.

- Radiolucency: Unlike metal implants, PEEK is radiolucent, allowing for clearer imaging during post-operative monitoring and reducing radiation exposure for patients.

- Chemical stability: PEEK is resistant to corrosion and degradation, ensuring long-term stability in the body.

- Biocompatibility: PEEK exhibits excellent biocompatibility, minimizing the risk of adverse reactions and inflammation.

Studies Supporting PEEK’s Efficacy

Numerous studies have demonstrated the efficacy of PEEK implants in reducing infection risks and improving patient outcomes:

- A study by Webster et al. (2012) found that PEEK implants exhibited anti-infective properties and promoted osteointegration compared to titanium and poly(ether ether ketone) implants in a rat model of bone infection.

- Rochford et al. (2019) reported that PEEK implants showed equivalent infection burden and immunological responses compared to metallic implants in vitro and in a murine model of fracture-related infection.

- Suojanen et al. (2019) observed no differences in infection rates between patient-specific PEEK implants and conventional mini-plates in mandibular bilateral sagittal split osteotomy, with up to 3-year follow-up.

The use of PEEK implants can significantly reduce infection risks associated with medical implants. By minimizing the formation of bacterial biofilms and promoting osseointegration, PEEK materials contribute to improved implant stability and patient comfort. As the demand for safer and more effective implant solutions grows, PEEK is poised to play an increasingly important role in achieving better outcomes for patients undergoing implant procedures.

Clinical Applications and Success Stories

PEEK implants have demonstrated remarkable success in various clinical applications, particularly in orthopedics, dentistry, and spinal surgery. The use of PEEK materials has significantly reduced infection risks, improved implant stability, and increased patient comfort in these fields. AIP Precision Machining has been at the forefront of this innovation, providing highly precise PEEK components that meet the rigorous demands of these medical fields, thereby enhancing patient outcomes and reducing infection risks.

PEEK implants have demonstrated remarkable success in various clinical applications, particularly in orthopedics, dentistry, and spinal surgery. The use of PEEK materials has significantly reduced infection risks, improved implant stability, and increased patient comfort in these fields. AIP Precision Machining has been at the forefront of this innovation, providing highly precise PEEK components that meet the rigorous demands of these medical fields, thereby enhancing patient outcomes and reducing infection risks.

Orthopedic Implants

In orthopedic surgery, PEEK implants have shown promising results in minimizing infection risks and enhancing patient outcomes. Traditional metal implants, such as those made of titanium or stainless steel, are associated with higher rates of infection due to their susceptibility to bacterial adhesion and biofilm formation. PEEK, on the other hand, exhibits inherent resistance to bacterial colonization, making it an ideal material for orthopedic implants.

Clinical studies have demonstrated the effectiveness of PEEK implants in reducing infection rates in hip and knee replacements. A retrospective analysis of patients who underwent total hip arthroplasty with PEEK acetabular components reported a significantly lower infection rate compared to those with conventional metal implants. Similarly, in total knee arthroplasty, the use of PEEK tibial components has been associated with reduced incidence of periprosthetic joint infections.

The biocompatibility and mechanical properties of PEEK also contribute to improved implant stability and osseointegration. The elastic modulus of PEEK is closer to that of bone compared to metal implants, reducing stress shielding and promoting better load transfer to the surrounding bone tissue. This enhanced load distribution promotes bone remodeling and reduces the risk of implant loosening or failure.

Dental Implants

PEEK has emerged as a promising alternative to titanium in dental implantology. Dental implants are susceptible to peri-implantitis, an inflammatory condition caused by bacterial infection that can lead to implant failure. PEEK’s resistance to bacterial adhesion and its biocompatibility make it an attractive option for minimizing the risk of peri-implantitis.

Clinical trials have reported favorable outcomes with PEEK dental implants. A prospective study comparing PEEK and titanium dental implants found no significant differences in implant survival rates, marginal bone loss, or soft tissue health between the two materials. Additionally, PEEK implants demonstrated excellent aesthetic results, as their color closely resembles that of natural teeth.

The use of PEEK abutments in implant-supported prostheses has also shown promising results in reducing the risk of bacterial colonization at the implant-abutment interface. The smooth surface of PEEK abutments minimizes plaque accumulation and facilitates easier cleaning, thereby reducing the likelihood of peri-implant infections.

Spinal Implants

PEEK has revolutionized the field of spinal surgery, offering numerous advantages over traditional metal implants. In spinal fusion procedures, PEEK cages and interbody devices have demonstrated excellent biocompatibility, radiolucency, and mechanical stability.

The radiolucent nature of PEEK allows for improved postoperative imaging, enabling surgeons to assess fusion progress and identify any potential complications more effectively. This is particularly important in detecting and managing postoperative infections, as early diagnosis is crucial for successful treatment.

Moreover, PEEK spinal implants have shown reduced rates of subsidence and migration compared to metal implants. The elastic modulus of PEEK, being closer to that of cortical bone, helps distribute the load more evenly across the implant-bone interface, reducing stress concentrations and minimizing the risk of implant-related complications.

Clinical studies have reported favorable outcomes with PEEK spinal implants, including high fusion rates, reduced postoperative pain, and improved patient satisfaction. The use of PEEK in minimally invasive spinal surgery has also gained popularity, as its radiolucency allows for better visualization of the surgical site and facilitates precise implant placement.

In conclusion, the clinical applications of PEEK implants in orthopedics, dentistry, and spinal surgery have demonstrated significant success in reducing infection risks, improving implant stability, and enhancing patient comfort. The inherent properties of PEEK, such as its resistance to bacterial adhesion, biocompatibility, and mechanical similarity to bone, make it a superior choice over traditional metal implants. As research continues to advance, the role of PEEK in minimizing infection risks and optimizing patient outcomes in healthcare is expected to grow further.

Future Prospects of PEEK in Medical Implants

As PEEK continues to gain recognition for its unique properties and potential in medical implants, the future prospects of this material are promising. Researchers and industry experts are actively exploring new avenues to further enhance the performance and applicability of PEEK in healthcare.

Ongoing Research

One of the key areas of ongoing research is the development of biodegradable PEEK variants. While PEEK’s stability and durability are advantageous for long-term implants, there is a growing interest in creating PEEK materials that can safely degrade within the body over time. This would be particularly beneficial for temporary implants or devices that are only needed for a specific healing period. Researchers are investigating various strategies, such as incorporating biodegradable segments into the PEEK polymer chain or developing PEEK composites with biodegradable components.

Another focus of research is the modification of PEEK surfaces to promote better osseointegration. Although PEEK is biocompatible, its relatively inert surface can sometimes limit the direct bonding between the implant and the surrounding bone tissue. To address this, researchers are exploring surface treatments, such as plasma treatment or coating with bioactive materials like hydroxyapatite, to enhance the bone-bonding ability of PEEK implants. These surface modifications aim to improve implant stability and reduce the risk of implant loosening over time.

Potential Innovations

Looking ahead, several potential innovations could revolutionize the use of PEEK in medical implants. One exciting prospect is the development of smart PEEK implants that incorporate sensors or drug delivery systems. These intelligent implants could monitor the healing process, detect any signs of infection, or release therapeutic agents directly at the implant site. Such advancements would enable personalized and targeted treatment, improving patient outcomes and reducing complications.

Looking ahead, several potential innovations could revolutionize the use of PEEK in medical implants. One exciting prospect is the development of smart PEEK implants that incorporate sensors or drug delivery systems. These intelligent implants could monitor the healing process, detect any signs of infection, or release therapeutic agents directly at the implant site. Such advancements would enable personalized and targeted treatment, improving patient outcomes and reducing complications.

Another area of potential innovation is the combination of PEEK with other advanced materials to create hybrid implants with enhanced properties. For example, the integration of PEEK with shape memory alloys could lead to implants that can adapt and respond to the body’s natural movements. Similarly, the incorporation of conductive materials into PEEK could enable electrical stimulation of the surrounding tissues, promoting faster healing and regeneration.

The use of 3D printing technology is also expected to play a significant role in the future of PEEK implants. With the ability to create patient-specific implants based on individual anatomical data, 3D printing could revolutionize the design and manufacturing of PEEK implants. This would allow for more precise fitting, improved functionality, and reduced risk of implant failure. As 3D printing techniques continue to advance, the possibilities for customized PEEK implants are vast.

Moreover, the increasing adoption of minimally invasive surgical techniques is driving the demand for smaller and more versatile PEEK implants. The development of miniaturized PEEK components and instruments could enable less invasive procedures, reducing patient trauma and accelerating recovery times.

In conclusion, the future prospects of PEEK in medical implants are highly promising. With ongoing research focused on biodegradability, surface modifications, and smart implant technologies, PEEK is poised to play an even greater role in advancing patient care. As innovations in materials science, manufacturing techniques, and surgical approaches converge, PEEK implants have the potential to revolutionize the field of medical implants, offering safer, more effective, and personalized solutions for a wide range of healthcare applications. The continued collaboration between researchers, clinicians, and industry partners will be crucial in driving these advancements forward and realizing the full potential of PEEK in medical implants.

Advantages of PEEK over Traditional Implant Materials

PEEK (polyetheretherketone) has emerged as a promising alternative to traditional implant materials such as titanium and stainless steel due to its unique combination of biocompatibility, mechanical properties, and radiological advantages. These characteristics make PEEK an ideal choice for minimizing infection risks and improving patient outcomes in healthcare settings.

Biocompatibility

One of the key advantages of PEEK is its excellent biocompatibility. Unlike metal implants, which can cause allergic reactions or release metal ions into the body, PEEK is biologically inert and does not elicit adverse immune responses. This biocompatibility reduces the risk of inflammation and infection at the implant site, promoting faster healing and better long-term results.

PEEK’s biocompatibility also enables better integration with the surrounding tissue. The material’s surface properties encourage cell adhesion and growth, facilitating the formation of a stable interface between the implant and the host tissue. This enhanced osseointegration reduces the likelihood of implant loosening or failure, which can be a significant source of infection.

Mechanical Properties

PEEK’s mechanical properties closely resemble those of human bone, making it an ideal material for load-bearing implants. The elastic modulus of PEEK is similar to that of cortical bone, which helps to distribute stress more evenly across the implant-bone interface. This stress distribution minimizes the risk of stress shielding, a phenomenon in which the implant bears an excessive load, leading to bone resorption and weakening around the implant. By maintaining a more natural stress distribution, PEEK implants promote bone health and reduce the risk of implant-related infections.

Moreover, PEEK’s high strength-to-weight ratio and excellent fatigue resistance ensure long-term stability and durability of the implant. These properties are particularly important in load-bearing applications, such as spinal implants and orthopedic devices, where implant failure can lead to serious complications and increased infection risk.

Radiological Advantages

PEEK’s radiolucency is another significant advantage over traditional metal implants. Unlike metal, which can create artifacts and obscure imaging results, PEEK is transparent to X-rays, CT scans, and MRI. This radiolucency allows for clearer visualization of the implant site and surrounding tissues, enabling more accurate diagnosis and monitoring of potential complications, including infections.

The ability to obtain high-quality imaging is crucial for early detection and timely intervention in case of implant-related infections. With PEEK implants, healthcare professionals can more easily identify signs of infection, such as fluid collections or soft tissue abnormalities, and initiate appropriate treatment promptly. This early intervention can prevent the progression of infection and minimize the risk of serious complications.

In summary, PEEK’s biocompatibility, mechanical properties, and radiological advantages make it a superior choice over traditional implant materials for minimizing infection risks in healthcare. By promoting better tissue integration, maintaining natural stress distribution, and allowing for clearer imaging, PEEK implants contribute to improved patient comfort, faster recovery, and reduced incidence of implant-related infections. As the demand for safer and more effective implant solutions grows, PEEK is poised to play an increasingly important role in achieving better outcomes for patients undergoing implant procedures.

Conclusion

The use of PEEK implants in healthcare has proven to be a game-changer in minimizing infection risks and improving patient outcomes. AIP Precision Machining’s expertise in producing highly precise PEEK parts plays a crucial role in this advancement, ensuring that medical devices and implants are of the highest quality and performance.

PEEK’s unique properties, including its biocompatibility, mechanical strength, and radiolucency, make it an ideal material for various medical applications, such as orthopedic, dental, and spinal implants. By reducing the risk of bacterial adhesion and promoting better osseointegration, PEEK implants offer a safer and more effective alternative to traditional metal implants.

As research continues to advance, the future of PEEK in medical implants looks promising. With ongoing studies focusing on biodegradability, surface modifications, and smart implant technologies, PEEK is poised to play an even greater role in enhancing patient care and reducing the incidence of implant-related complications. As healthcare professionals strive to provide the best possible outcomes for their patients, the adoption of PEEK implants will undoubtedly contribute to a safer and more successful future in medical implantology.

AIP Precision Machining’s expertise in producing highly precise PEEK parts plays a crucial role in this advancement, ensuring that medical devices and implants are of the highest quality and performance.

Medical professionals with complex projects and stringent requirements can reach out to AIP’s experts for consultation and support. Our team is ready to collaborate with you to deliver precision-engineered solutions that meet your specific needs. Contact us today to discuss how we can assist with your medical device projects and contribute to your success.

FAQs

What benefits do PEEK implants offer?PEEK implants provide several advantages over other materials like zirconium and titanium, notably due to their good color stability, appealing appearance, and an elastic modulus that closely matches that of cortical bone. These properties make PEEK a popular choice for dental implants and various other prosthetic applications.

How does PEEK compare to titanium in terms of infection rates?A review comparing infection rates across materials used in cranioplasty and craniofacial reconstruction found that titanium mesh had an infection rate of 7.71%, titanium plates had 8.31%, and PEEK implants had 7.89%. These figures suggest that PEEK is comparable to titanium in terms of infection risk.

What is PEEK, and why is it used in medical implants?PEEK, or polyether ether ketone, is a high-performance polymer widely utilized in the manufacturing of medical implants and devices. It is known for its excellent load-bearing capacity and compatibility with bone, making it a superior alternative to many metal implants.

In what medical applications are PEEK implants used?The superior properties of PEEK make it ideal for various implantology applications. These include finger prostheses, frameworks for removable partial dentures (RPD) and fixed partial dentures (FPD), as well as dental implants.