PEEK and TORLON 4203 represent the pinnacle of high-performance thermoplastics for critical aerospace applications. Torlon PAI (polyamide-imide) demonstrates exceptional thermal resistance with continuous use temperatures up to 260°C, significantly outperforming many competing materials. Additionally, PAI nanofibers exhibit filtering efficiency above 90% for particles sized at 0.3 microns, making them ideal for specialized aerospace filtration systems.

PEEK and TORLON 4203 represent the pinnacle of high-performance thermoplastics for critical aerospace applications. Torlon PAI (polyamide-imide) demonstrates exceptional thermal resistance with continuous use temperatures up to 260°C, significantly outperforming many competing materials. Additionally, PAI nanofibers exhibit filtering efficiency above 90% for particles sized at 0.3 microns, making them ideal for specialized aerospace filtration systems.

When selecting materials for mission-critical aerospace components, engineers must balance multiple performance factors. Torlon bushings maintain their strength and stability in extreme temperature ranges from -40° to 260°C, while also offering excellent chemical resistance against harsh substances commonly found in aerospace environments.

Furthermore, Torlon PAI finds extensive applications in thermal isolators, screws, tubing, and structural components. Both PEEK and Torlon are widely recognized for their exceptional performance in aerospace applications, though each offers distinct advantages depending on specific requirements. This comparative analysis examines the critical performance metrics that determine material selection for high-temperature, high-stress aerospace environments where component failure is not an option.

Why Compare PEEK and TORLON 4203 in Aerospace?

Material selection stands as the foundation of modern aerospace engineering, directly influencing performance, safety, and operational costs. The comparative analysis between PEEK and TORLON 4203 has become increasingly relevant for engineers facing stringent performance requirements in critical applications.

Material selection challenges in high-performance aerospace parts

Aircraft components must perform reliably under extraordinarily challenging conditions. These parts endure extreme temperature fluctuations, exposure to aggressive chemicals, and substantial mechanical stress. Consequently, aerospace engineers face complex material selection decisions requiring meticulous evaluation across multiple performance criteria.

For aerospace applications, materials must maintain structural integrity under temperatures ranging from -40°F (-40°C) to over 500°F (260°C).

Moreover, components frequently encounter jet fuels, de-icing chemicals, and various lubricants throughout their service life. Both PEEK and TORLON 4203 offer exceptional solutions to these challenges, albeit with different performance profiles.

Overview of FAA-compliant plastics for critical components

Regulatory compliance remains paramount in aerospace manufacturing. High-performance polymers used in aircraft applications must meet stringent FAA flammability standards, particularly those specified in FAR 25.853. Many materials undergo continuous testing for flammability, smoke development, and toxicity to ensure they meet these critical safety requirements.

PEEK and TORLON 4203 have established track records of compliance with aerospace industry standards. Both materials appear on Qualified Parts Lists (QPL) for major OEMs including Boeing and Airbus, authorizing their use in demanding structural applications.

Role of high-temperature plastics in aircraft systems

High-temperature polymers have fundamentally transformed aerospace component design. In propulsion systems, TORLON PAI and PEEK deliver exceptional chemical resistance alongside remarkable strength-to-weight ratios. Their unique properties enable innovative system designs that simultaneously reduce weight and cost.

PEEK maintains its mechanical properties at temperatures up to 482°F (250°C), whereas TORLON excels with continuous use temperatures reaching 500°F (260°C). This thermal stability makes them ideal for applications including bushings in blocker door assemblies, screws requiring EMI/RFI transparency, external light housings, and thermal isolators.

Primarily, the choice between these materials depends on specific application requirements.

Head-to-Head Comparison of Key Material Properties

When evaluating high-performance thermoplastics for critical aerospace applications, direct comparison of mechanical, thermal, and chemical properties becomes essential for engineers making material selection decisions.

PEEK compressive strength vs TORLON 4203 tensile performance

TORLON 4203 exhibits exceptional compressive strength at 24,000 psi, which is double that of unfilled PEEK and 30% higher than ULTEM PEI. Regarding tensile properties, TORLON 4203 demonstrates impressive performance with a tensile strength of 18,000 psi and a tensile modulus of 600,000 psi.

In contrast, PEEK offers tensile strength of approximately 16,000 psi. Indeed, TORLON maintains superior mechanical properties even at elevated temperatures, retaining its strength and stiffness at temperatures up to 275°C.

Thermal resistance: TORLON max service temperature vs PEEK

The maximum continuous operating temperature for TORLON 4203 reaches 500°F (260°C), slightly outperforming PEEK which operates reliably up to 482°F (250°C). This difference becomes crucial in aerospace applications where components face extreme thermal environments.

Furthermore, TORLON 4203 boasts a heat deflection temperature of 532°F (278°C) at 264 psi, providing excellent dimensional stability under thermal stress.

Moisture absorption and dimensional stability

Notably, TORLON 4203 absorbs 0.4% moisture in 24 hours, which is higher than PEEK. This characteristic requires consideration when designing components for wet environments. At 50% relative humidity and 70°F, TORLON’s water absorption and resultant dimensional growth are 30-40% less even after 400 days.

Wear resistance: TORLON 4203 vs PEEK in dry and lubricated conditions

TORLON 4203 delivers exceptional wear resistance with a limiting PV factor of 12,500 psi × ft/min and a wear factor “k” of 50 × 10^-10 in³-min/ft-lb-hr. The wear resistance is maximized through post-curing after machining, improving limiting PV and wear rate by approximately 5X.

Chemical compatibility with fuels, oils, and hydraulic fluids

TORLON exhibits excellent resistance to a wide range of automotive and aviation fluids, primarily jet fuels, gasoline, and most hydrocarbon-based solvents. PEEK demonstrates broader chemical resistance, especially against acids, bases, and organic solvents. For aerospace applications requiring FDA and USDA purity standards, however, PEEK is often preferred as TORLON does not meet these specific requirements.

Flammability ratings and outgassing behavior in aerospace

From a safety perspective, TORLON 4203 achieves a UL94 V-0 flammability rating with low smoke generation. Both TORLON PAI and PEEK qualify as low-outgassing materials with Total Mass Loss (TML) levels below 1% and Collected Volatile Condensable Material (CVCM) less than 0.1%, meeting NASA’s stringent requirements for spacecraft materials.

Application-Specific Use Cases in Aerospace Systems

Both PEEK and TORLON 4203 excel in specific aerospace applications, addressing unique design challenges through their distinctive performance characteristics.

PEEK components for aircraft systems: tubing, seals, and housings

PEEK tubing serves multiple functions across aerospace systems, primarily acting as protective sheathing and fluid transfer conduits for high-temperature fluids. Its exceptional strength-to-weight ratio makes it particularly valuable for HPLC pressure applications, effectively replacing heavier stainless steel components. PEEK seals control liquid and gas flow in valves, compressors, and blowout preventers, remaining chemically stable when exposed to aviation fluids. Additionally, valve seats manufactured from PEEK maintain their rigidity despite continuous exposure to hot water and steam.

TORLON 4203 parts: bushings, valve seats, and structural brackets

Torlon 4203 represents the toughest and most impact-resistant Torlon grade, making it ideal for highly loaded wheels, rollers, and balls. In aerospace applications, Torlon 4203 excels in valve seats requiring dimensional stability, thermal insulators, and electrical components demanding heat resistance and low flammability. Specifically, F-16 fighter aircraft utilize Torlon 4203 for fuel connectors in auxiliary tanks, withstanding pressures beyond 650 psi while resisting jet fuel exposure.

Suitability for high-altitude and cryogenic environments

PEEK demonstrates remarkably low water absorption (0.03%) and minimal outgassing in vacuum environments, making it suitable for high-altitude aerospace applications. Conversely, Torlon maintains excellent properties under cryogenic conditions without becoming brittle like other resins. Both materials provide reliable performance at extreme altitudes where temperature fluctuations are severe.

Performance in fuel-exposed and high-vibration zones

PEEK bushings in blocker door assemblies deliver precise performance across temperature ranges from -40°F to 500°F without lubrication. For vibration-intensive environments, Torlon 4203 maintains dimensional integrity while exposed to continuous vibration in fuel connectors.

Precision Machining and Certification Considerations

Precision manufacturing remains paramount in aerospace applications where component failure is not an option. For high-performance plastics like PEEK and TORLON 4203, specialized machining expertise ensures optimal performance in mission-critical applications.

AS9100D certified machining for aerospace-grade plastics

Aerospace manufacturing demands adherence to AS9100D certification, which builds upon ISO 9001:2015 by adding specifications tailored explicitly for aviation, space, and defense organizations.

This stringent standard requires implementation of risk mitigation processes, strict configuration management, and comprehensive validation procedures. Accordingly, certified manufacturers maintain complete traceability records for a minimum of 10 years, ensuring accountability throughout the production process.

±0.002 mm tolerances in tight tolerance plastic parts

Premium aerospace manufacturers achieve tolerances as tight as ±0.002 mm, essential for components where precision directly impacts flight safety.

During their service life, such tight-tolerance parts maintain dimensional stability even after thermal cycling. Precision machining within climate-controlled environments ensures these exacting standards are met consistently, primarily for complex geometries across varied thermoplastic materials.

DFM for engineered plastic parts in aircraft

Design for manufacturability in aerospace plastic components requires avoiding metal machining companies regardless of their experience, as the contamination risk is too high.

Furthermore, PEEK machining demands specific tooling approaches: carbide tooling for short production runs and polycrystalline diamond tooling for tight-tolerance parts.

Rapid prototyping of custom TORLON and PEEK parts

Short-run prototype parts can be produced using aluminum prototype tooling, low-cavity steel molds, or even 3D printed tooling inserts where appropriate. This approach allows validation of designs before investing in full production tooling.

Partner With a Certified Leader in Aerospace Polymer Machining From material selection to mission-critical part production, AIP Precision Machining brings over 40+ years of experience and AS9100D-certified precision to your aerospace programs.

Conclusion

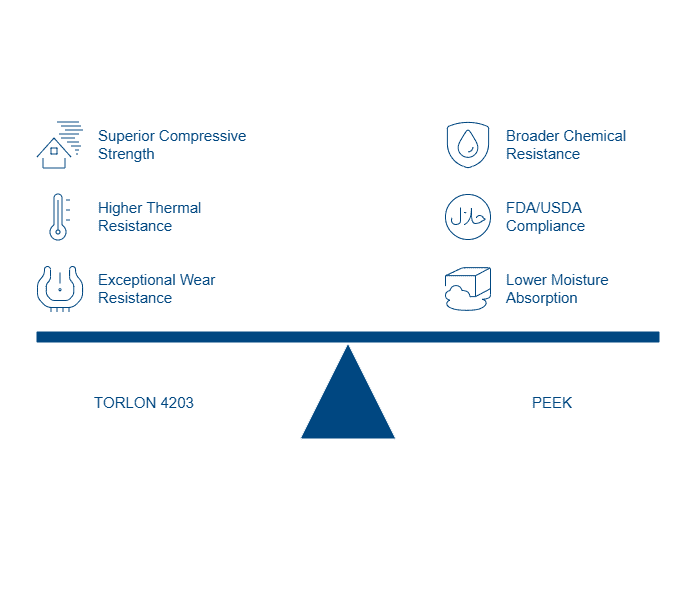

PEEK and TORLON 4203 remain essential high-performance thermoplastics in aerospace component design, each excelling in different performance domains. TORLON 4203 offers unmatched compressive strength and superior dimensional stability at elevated temperatures, making it the material of choice for high-load, high-heat applications such as fuel connectors, valve seats, and structural brackets.

On the other hand, PEEK presents key advantages in applications requiring low moisture absorption, chemical resistance, and long-term performance in aggressive environments. Its ability to maintain structural integrity in high-humidity or chemically exposed systems—combined with its low outgassing and compliance with FDA/USDA standards—makes it indispensable in aerospace fluid management and electrical insulation applications.

The optimal choice between these two materials depends on precise application demands. Aerospace engineers must assess a balance of thermal resistance, wear performance, chemical compatibility, and environmental exposure. Regardless of material, precision manufacturing is critical—particularly for flight-critical components requiring tolerances as tight as ±0.002 mm.

Partner With a Certified Aerospace Machining Expert

Whether you’re specifying bushings, thermal isolators, or EMI-safe connectors, AIP Precision Machining offers AS9100D-certified expertise, polymer-only machining, and over 40+ years of experience supporting mission-critical aerospace programs. Contact us for consultation on your next PEEK or TORLON application—from rapid prototyping to full-scale production.

FAQs

Q1. How does PEEK compare to TORLON 4203 in aerospace applications?

PEEK and TORLON 4203 are both high-performance thermoplastics used in aerospace, each with distinct advantages. TORLON 4203 excels in compressive strength and thermal resistance, while PEEK offers better moisture resistance and chemical compatibility. The choice between them depends on specific application requirements.

Q2. What are the key advantages of TORLON 4203 in aerospace components?

TORLON 4203 offers exceptional compressive strength, superior mechanical properties at high temperatures, and excellent wear resistance. It’s ideal for highly loaded wheels, valve seats requiring dimensional stability, and fuel connectors that need to withstand high pressures in extreme environments.

Q3. In which aerospace applications does PEEK excel?

PEEK is particularly suitable for protective tubing, seals controlling liquid and gas flow, and components exposed to various chemicals. It also performs well in high-altitude applications due to its low water absorption and minimal outgassing in vacuum environments.

Q4. What certifications are important for aerospace plastic machining?

AS9100D certification is crucial for aerospace manufacturing. It builds upon ISO 9001:2015 by adding specifications for aviation, space, and defense organizations. This certification ensures strict quality control, risk mitigation, and traceability in the production process.

Q5. How tight are the tolerances achievable in aerospace plastic parts?

Premium aerospace manufacturers can achieve tolerances as tight as ±0.002 mm for plastic parts. This level of precision is essential for components where dimensional accuracy directly impacts flight safety and performance. Specialized machining expertise and climate-controlled environments are necessary to consistently meet these exacting standards.