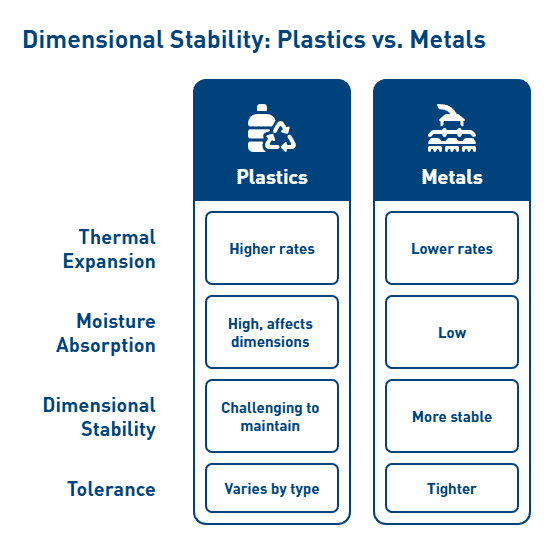

Drawings of plastic parts often specify tolerances that are tighter than the practical limitations for dimensionally stable plastics. Unlike metals, plastics present unique engineering challenges due to their higher thermal expansion rates, moisture absorption properties, and residual stress behaviors that significantly impact dimensional stability. For instance, nylon can absorb moisture at an extreme rate, with test specimens showing an 8.8% increase in mass and a 2% increase in length at saturation. The dimensional stability of plastics is particularly critical in applications requiring precise fit and consistent dimensions, as even minor variations can compromise functionality.

Consequently, understanding the factors affecting dimensional stability becomes essential for engineers working with precision plastic components. Temperature fluctuations cause different expansion rates in plastics compared to metals, with materials like UHMW exhibiting a coefficient of thermal expansion of .0001/inch/degree, resulting in movement of .012″ per degree of temperature change in a 10′ piece. Additionally, water absorption varies significantly between plastic types, with some engineering plastics swelling when exposed to humidity, further affecting dimensional accuracy. While some materials like Acetal can maintain tight tolerances of +/-.001 on most dimensions, others require more generous allowances, with industry guidelines recommending minimum machining tolerances of 0.2% of the nominal value. This article explores the critical considerations for achieving and maintaining dimensional stability in plastic parts across various environmental conditions and applications.

Thermal Expansion and Its Role in Dimensional Drift

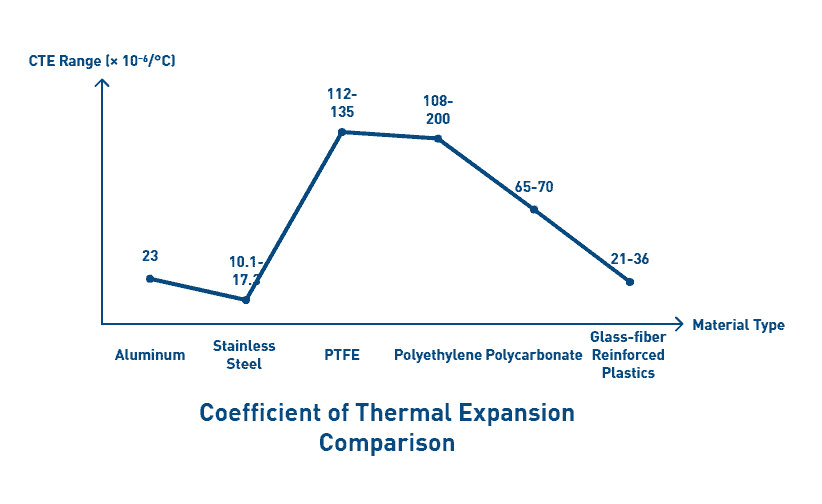

Thermal expansion represents one of the primary challenges when designing dimensionally stable plastics components. Most plastic materials expand and contract at rates three to ten times greater than metals when subjected to temperature changes. This fundamental property affects both the design and functional performance of precision plastic components throughout their lifecycle.

CTE Comparison: Plastics vs Metals

The Coefficient of Thermal Expansion (CTE) measures the dimensional change of a material per degree of temperature change. Generally, common metals like aluminum exhibit CTEs around 23 × 10⁻⁶/°C, while stainless steel ranges from 10.1 to 17.3 × 10⁻⁶/°C. In contrast, engineering plastics show significantly higher values:

- PTFE: 112-135 × 10⁻⁶/°C

- Polyethylene: 108-200 × 10⁻⁶/°C

- Polycarbonate: 65-70 × 10⁻⁶/°C

- Glass-fiber reinforced plastics: 21-36 × 10⁻⁶/°C

These differences become especially problematic in applications where plastic parts interface with metal components. Even though plastic parts may maintain tight tolerances during manufacturing, dimensional drift occurs as environmental temperatures fluctuate.

Temperature-Dependent Expansion in PEEK and PTFE

High-performance polymers like PEEK and PTFE demonstrate complex thermal expansion behaviors. Studies analyzing these materials up to 240°C show that their expansion characteristics are temperature-dependent. Importantly, the thermal diffusivity of composite materials containing PTFE/PEEK matrices is governed primarily by the polymer rather than reinforcing materials. Furthermore, adding carbon fibers enhances thermal stability at room temperature (25°C).

Design Revisions for Thermal Mismatch in Assemblies

When plastic components must interface with other materials, engineers should specifically account for expansion differences. If dimensional change from thermal expansion is constrained, excessive tensile, shear, or compressive stress can develop in the plastic part, potentially causing premature failure.

Two design approaches exist for addressing thermal expansion mismatches between materials. First, selecting adhesives with CTEs similar to the joined materials; second, employing more flexible materials to compensate for the differences. Moreover, for applications requiring enhanced dimensional stability, reinforcing thermoplastics with glass fibers or other fillers effectively reduces thermal expansion rates while improving mechanical properties.

Moisture Absorption and Humidity-Induced Swelling

Unlike thermal expansion, moisture absorption presents a distinct challenge for dimensionally stable plastics in humid environments. Moisture absorption is defined as a material’s capacity to absorb water from its surroundings, causing volumetric expansion and potentially altering mechanical properties.

Water Uptake in Nylon 6 and Dimensional Impact

Nylon’s exceptional water absorption capabilities make it a textbook example of humidity-induced dimensional changes. At room temperature under normal atmospheric conditions (35-65% relative humidity), unfilled nylon equilibrates at approximately 1.5-2% moisture content by weight. However, when fully immersed, this value increases dramatically to 5-8%. This absorption significantly impacts dimensions—a nylon 6 test specimen immersed in water exhibited an 8.8% increase in mass and a 2% increase in length at saturation.

Water molecules force polymer chains apart through hydrogen bonding, creating volumetric expansion. For unfilled nylon 6 or nylon 6/6, this typically results in dimensional growth of 0.5-0.6% at room temperature. At higher temperatures, both absorption rates and dimensional changes increase proportionally. Although glass fiber reinforcement can reduce these dimensional shifts to approximately 0.1% per inch of part dimension, even highly filled nylon will still expand by about 0.001 inch per inch.

Saturation Timeframes and Long-Term Effects

The time required to reach moisture saturation varies significantly based on material thickness and environmental conditions. For a 60mm diameter × 3mm thick disk of nylon 6, reaching 80% of equilibrium absorption takes approximately 330 hours in 20°C water, while achieving the same level in atmospheric conditions (20°C, 60% RH) requires about 4,110 hours. Full saturation typically takes 2.5 times longer.

For thicker components, saturation times increase exponentially. A 20mm thick cast nylon 6 piece requires approximately 15.6 years to fully saturate when continuously submerged in water at ambient temperature. After 10 months of constant submersion, the same material shows saturation depth of only 2.3mm.

Material Selection for Low Water Absorption

When dimensional stability is critical, engineers should select materials with minimal moisture absorption. Polytetrafluoroethylene (PTFE) stands alone as the only polymer exhibiting zero water absorption. Other materials with very low absorption rates include PEEK, PPS, PSU, PPSU, PEI, PVDF, PET, PPE, PP, and PE. Furthermore, acetal, PA12, PC, and ABS demonstrate relatively low absorption characteristics.

For applications requiring dimensional precision, the rule of thumb suggests that expansion due to moisture absorption must be considered for wall thicknesses up to 5mm, sometimes for thicknesses between 5-10mm, but generally not for thicknesses exceeding 10mm. Nevertheless, even materials typically regarded as dimensionally stable can exhibit surprising dimensional responses in close-tolerance assemblies.

Residual Stress, Creep, and Post-Molding Shrinkage

Residual stress, creep, and post-molding shrinkage present persistent challenges for maintaining dimensionally stable plastics throughout their service life. Despite often being overlooked in design considerations, these factors critically influence both short and long-term performance of precision plastic components.

Stress from Extrusion and Machining Operations

Residual stress develops when polymer molecules cannot achieve their preferred orientation during manufacturing processes. Previously ignored because of difficulty in quantification, these internal stresses significantly impact part performance through dimensional instability, optical distortion, and reduced mechanical properties. Extrusion operations create non-uniform stress profiles, with studies showing a linear correlation between residual stress and temperature differences at pipe walls. Similarly, machining introduces stress through several mechanisms: frictional heat generation at tool contact points, improper cutting tool design, and excessive cutting speeds that cause localized overheating. Notably, tight clamping during machining transfers stress to the workpiece, potentially causing warpage once released.

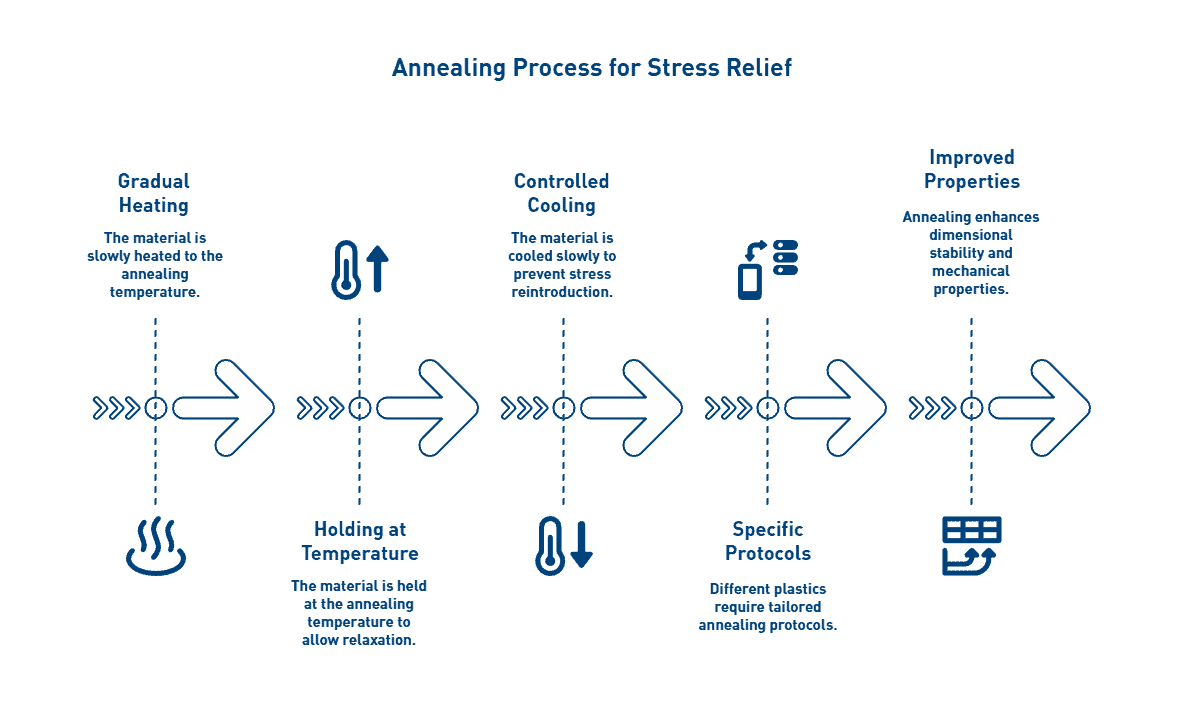

Annealing Techniques for Stress Relief

Annealing effectively eliminates internal stresses through controlled heating below a material’s glass transition temperature. The process involves three critical phases: gradual heating to the designated temperature (typically one-third to half of the melting point), holding at that temperature to allow polymer chains to relax, and controlled cooling to prevent reintroducing stress. For optimal results, different plastics require specific annealing protocols—polycarbonate at 250°F (121°C) for minimal time, Ultem at 400°F (204°C) for two hours, and super resins at 400°F (204°C) for four hours. Essentially, annealing improves dimensional stability, enhances mechanical properties, reduces stress cracking, and increases chemical resistance.

Creep Strain from Improper Storage

Creep—the permanent deformation of material under static load over time—occurs notably in dimensionally stable plastics stored improperly. Subsequently, plastic parts change shape and exceed tolerance limits when subjected to mechanical loads during extended storage periods. The creep process advances through distinct stages: immediate strain upon first exposure, followed by steady-state deformation, and ultimately rapid progression before failure. Unlike metals, plastics change properties substantially with time under constant pressure and temperature. One documented example showed PVC extrusions improperly stacked during summer months that permanently deformed.

Post-Molding Shrinkage in Acetal and Polypropylene

Semi-crystalline polymers with glass transition temperatures below room temperature continue to shrink significantly after molding. Indeed, acetal homopolymer parts measuring within specifications immediately after production showed continued shrinkage of approximately 0.004 inches after just 24 hours. This phenomenon occurs because materials like polypropylene (Tg between -10°C and +15°C) and acetal (Tg of -78°C) remain above their glass transition temperature at room conditions, allowing continued crystallization. The resulting post-molding shrinkage can reach approximately 0.001 inch/inch in properly molded acetal parts. Furthermore, studies tracking properties over five weeks post-molding revealed increasing tensile strength and modulus alongside decreasing impact performance—all direct results of continued crystallization.

Best Practices for Tolerancing in CNC Machined Plastics

Achieving optimal tolerances in CNC machined plastics requires specialized techniques and material-specific considerations that differ substantially from metal machining processes. Accordingly, manufacturers must adapt their approaches to accommodate the unique properties of dimensionally stable plastics.

Plastic Machining Tolerances by Material Type

Material selection critically influences achievable tolerances in plastic machining operations. Acetal materials demonstrate excellent stability, permitting tolerances as tight as +/-.001″ on most dimensions. Meanwhile, PEEK components can maintain similar precision at +/-.001″. In contrast, nylon requires more generous allowances at +/-.002″, whereas softer materials like UHMW necessitate even broader tolerances of +/-.005″ due to their heightened thermal sensitivity. For close-tolerance applications, PEEK or POM (acetal) combined with controlled fixturing and temperature regulation can achieve exceptionally tight tolerances of ±0.01 mm.

Rough Machining and Relaxation Periods

Internal stress release represents a primary challenge when pursuing dimensionally stable plastics through machining. Initially, performing rough machining followed by a deliberate relaxation period allows internal stresses to dissipate prior to finishing operations. In some cases where tight tolerances must be achieved, plastic parts should be machined to a rough shape and allowed to relax for several days. Afterward, an annealing step before final machining further reduces stress levels. This approach proves particularly valuable for components with significant material removal.

Fixturing Techniques to Minimize Stress

Proper workholding fundamentally affects dimensional outcomes. Excessive clamping introduces residual stress that subsequently causes warpage once released. To counteract this, consider using double-sided adhesive tapes to secure plastic stock shapes, as tapes introduce minimal stress compared to mechanical clamping. Another effective approach involves clamping only sections of stock that will not become part of the finished component. For flexible materials like polypropylene, providing additional support for thin-walled sections prevents vibration and deflection.

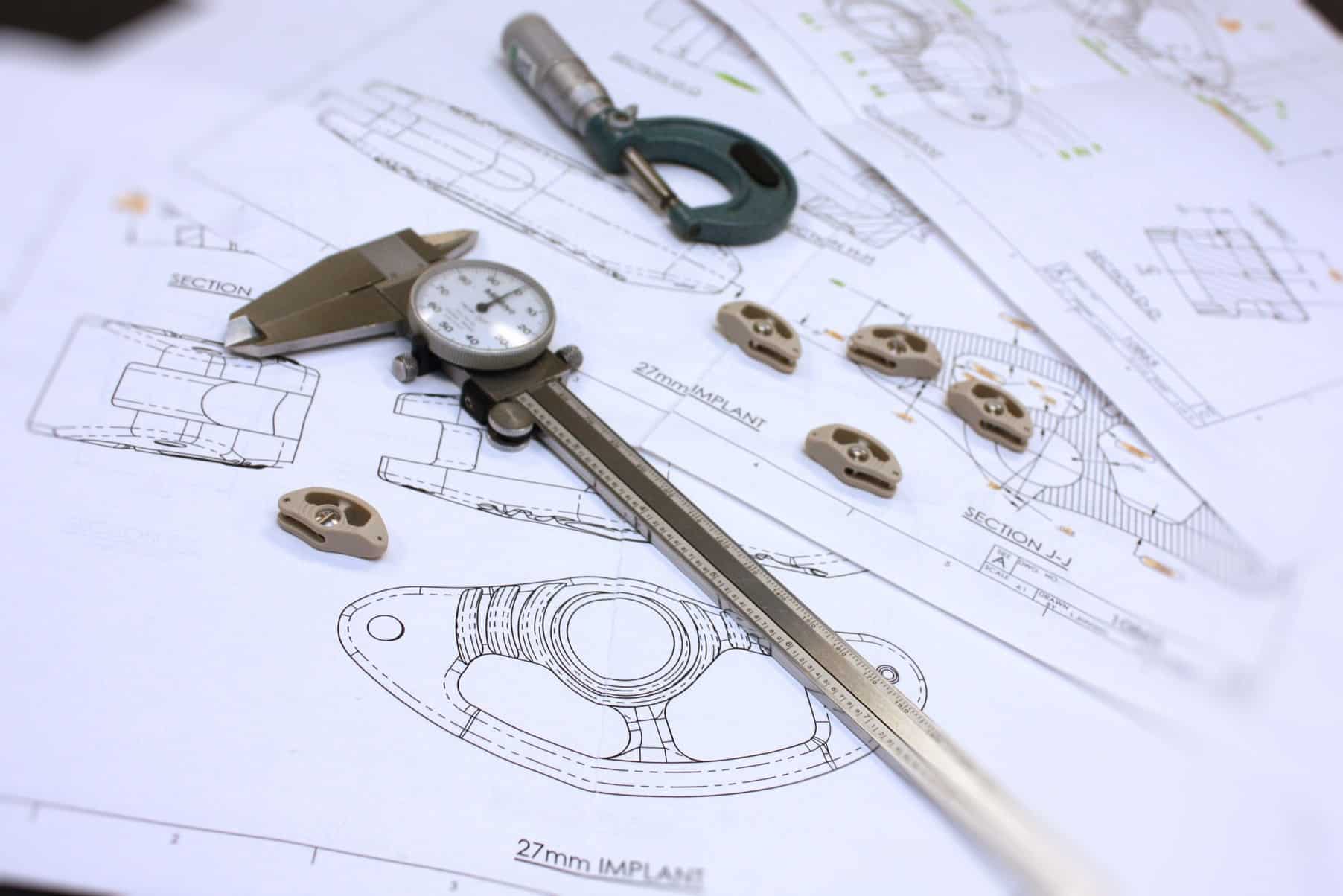

Precision Plastic Components for Aerospace and Medical

Aerospace and medical applications demand exceptional dimensional precision in plastic components. In these fields, quality control, tight tolerances, and engineered materials all play critical roles in reducing customer risk. <Get a Quote on Your Project. Submit your design for a tolerance assessment and learn how AIP ensures dimensional stability in every machined plastic part.> For aerospace applications, high-performance dimensionally stable plastics offer lightweight alternatives that improve fuel efficiency. Medical devices benefit from precisely machined plastic components that enhance fluid flow and device performance. The stringent requirements of these industries necessitate temperature-controlled manufacturing environments and frequently incorporate micro-molding techniques for extremely complex geometries with tolerances as tight as 0.015″.

Conclusion

Dimensional stability represents the cornerstone of successful plastic component design and manufacturing. Throughout this article, the complex interplay between material properties and environmental factors has demonstrated why achieving tight tolerance plastic parts requires specialized knowledge and techniques. Thermal expansion differences between plastics and metals, sometimes 3-10 times greater, necessitate careful material selection and design considerations, particularly for assemblies combining different materials. Moisture absorption further complicates matters, with materials like nylon exhibiting significant dimensional changes while alternatives such as PTFE, PEEK, and acetal offer superior stability in humid environments.

Residual stress management proves equally critical for dimensionally stable plastics. Proper annealing techniques, controlled machining operations, and appropriate fixturing all contribute significantly to maintaining dimensional accuracy. Consequently, engineers must consider not only initial tolerances but also long-term dimensional stability throughout a component’s service life.

Material selection ultimately determines the achievable tolerances for precision plastic components. Acetal and PEEK generally permit tolerances as tight as ±0.001 inches, while softer materials like UHMW require more generous allowances. Though achieving tight plastic machining tolerances presents challenges, specialized techniques such as rough machining followed by relaxation periods substantially improve results.

Advanced applications in aerospace and medical fields demand exceptional precision and reliability from plastic components. Engineers working in these sectors should Get a Quote on Your Project to receive a tolerance assessment and learn how manufacturing partners ensure dimensional stability in every machined plastic part. Additionally, quality control processes must account for temperature fluctuations, moisture effects, and stress relaxation to maintain dimensional accuracy over time.

The comprehensive approach to dimensionally stable plastics outlined in this article serves as a practical guide for engineers and designers facing tight tolerance requirements. Successful implementation of these principles enables the creation of precision components that maintain their dimensional integrity despite thermal variations, moisture exposure, and mechanical stresses—thereby ensuring optimal performance in even the most demanding applications.

FAQs

Q1. What factors affect the dimensional stability of plastic parts?

The main factors affecting dimensional stability of plastic parts are thermal expansion, moisture absorption, and residual stress. These can cause dimensional changes in plastic components over time and in different environmental conditions.

Q2. How does thermal expansion impact plastic parts compared to metal components?

Plastic materials typically expand and contract at rates 3-10 times greater than metals when subjected to temperature changes. This can lead to dimensional drift and potential issues in assemblies where plastic and metal components interface.

Q3. Which plastic materials offer the best dimensional stability in humid environments?

Materials with low moisture absorption rates like PTFE, PEEK, PPS, and acetal offer better dimensional stability in humid environments. PTFE stands out as the only polymer exhibiting zero water absorption.

Q4. What is annealing and how does it improve dimensional stability in plastic parts?

Annealing is a heat treatment process that eliminates internal stresses in plastic parts. It involves controlled heating below the material’s glass transition temperature, holding at that temperature, and then cooling slowly. This process improves dimensional stability, enhances mechanical properties, and reduces stress cracking.

Q5. What are the best practices for achieving tight tolerances in CNC machined plastic parts?

Best practices include selecting appropriate materials (e.g., acetal or PEEK for tighter tolerances), using rough machining followed by relaxation periods, employing proper fixturing techniques to minimize stress, and considering temperature-controlled manufacturing environments for precision components.