Plastic for electronic enclosures serve as a critical protective barrier in electrical and electronic equipment. In power generation and electronic systems, proper insulation prevents electrical currents from leaking or short-circuiting, which protects equipment, maintains system stability, and prevents hazards such as electrical shocks and fires. These protective housing solutions safeguard sensitive components from environmental factors while providing essential electrical isolation.

Additionally, the selection of appropriate plastic materials for electronic equipment enclosures directly impacts system reliability and safety. Plastics like polyethylene, polypropylene, and polystyrene are commonly used as insulators in various applications including electrical wiring, capacitors, transformers, and electronic devices. These non-conductive polymers offer high dielectric strength, thermal resistance, and mechanical durability to withstand harsh environments, including extreme temperatures, UV exposure, chemicals, and moisture. Specifically, materials such as PVC, polyethylene, and PTFE are frequently chosen for their excellent insulating qualities in electronics applications, while specialized plastics like Polyphenylene Oxide (PPO) combined with Polystyrene provide exceptional resistance to heat distortion and chemicals. This comprehensive guide examines the optimal materials, standards, and manufacturing considerations to ensure maximum protection for electronic components.

Key Protection Requirements for Plastic Electronic Enclosures

Effective plastic electronic enclosures must meet several critical protection requirements to ensure performance reliability and safety in diverse operating environments. These specifications determine how well the enclosure shields internal components from external threats.

Dielectric Strength and Electrical Isolation

Dielectric strength represents a fundamental property for plastic electronic enclosures, measuring their ability to withstand electrical voltage without breakdown. Materials with high dielectric strength prevent current leakage and electrical arcing. According to industry testing, sufficient dielectric strength requires materials to withstand at least 15 kV, even when equipment only needs to achieve 8 kV standards. This higher threshold ensures safety margins in real-world applications, particularly in regions prone to static electricity. Furthermore, proper isolation requires recessing metal components at least 2 cm to avoid discharge through openings, while air gaps should be closed with bonding or gasketing at least 0.5 cm wide.

Thermal Stability in High-Load Environments

Electronic components generate significant heat during operation, necessitating enclosure materials that maintain dimensional stability and structural integrity at elevated temperatures. Consequently, thermal management becomes essential to prevent component failure and potential fire hazards. Materials such as PEEK and PEI offer exceptional heat resistance for enclosures housing high-temperature applications.

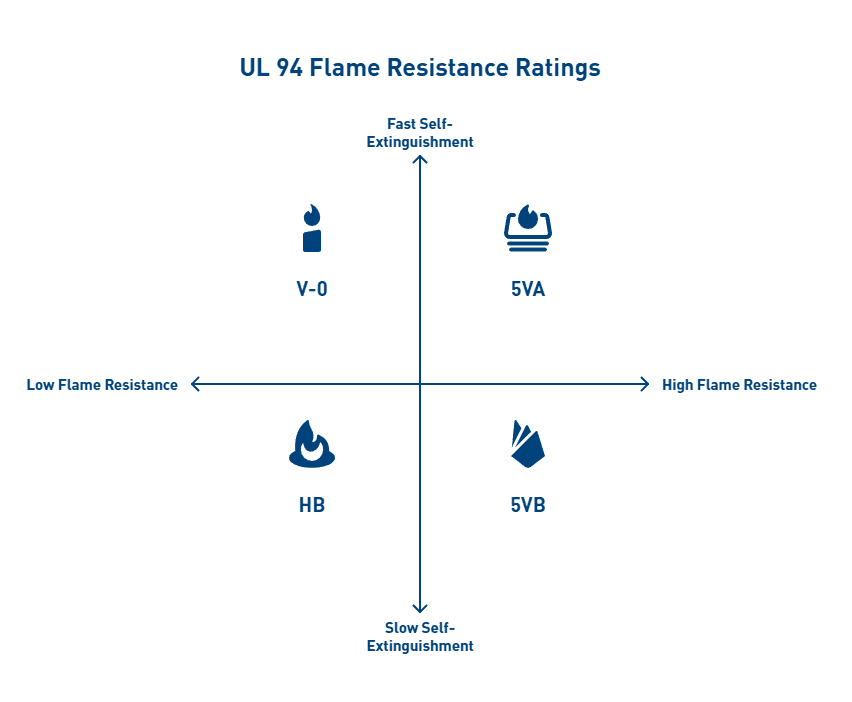

UL 94 Flame Ratings and Fire Safety

The UL 94 standard classifies plastic materials based on flammability characteristics through controlled burn tests. These ratings, in descending order of flame resistance, include:

- 5VA: Highest rating; withstands five flame applications without burn-through

- 5VB: Withstands five flame applications with minor burn-through allowed

- V-0: Self-extinguishes within 10 seconds; no flaming drips

- V-1: Self-extinguishes within 60 seconds; no flaming drips

- V-2: Self-extinguishes within 60 seconds; may have flaming drips

- HB: Slowest burn rate; least flame-retardant

Chemical Resistance in Harsh Operating Conditions

Chemical resistance describes a polymer’s ability to maintain mechanical integrity when exposed to specific chemical environments. Several factors affect this property, including temperature, chemical concentration, mechanical stress, and exposure duration. Therefore, plastic selection must consider the specific operating environment. Materials like PEEK offer high chemical resistance, while polycarbonate maintains excellent resistance to many acids but deteriorates when exposed to alkaline solutions.

Regulatory Compliance: ISO 10993, USP Class VI, Cleanroom Standards

For specialized applications, regulatory compliance becomes essential. ISO 10993 provides a rigorous standard for biological evaluation of medical devices, involving systemic toxicity, genotoxicity, and hemocompatibility tests. Meanwhile, USP Class VI certification involves three biological reactivity evaluations: acute systemic toxicity, intracutaneous testing, and implantation testing. For semiconductor applications, cleanroom compatibility (ISO Class 7/Class 10,000) ensures particulate control in manufacturing environments.

Comparison of High-Performance Plastics for Enclosure Applications

High-performance plastics offer distinct advantages for electronic enclosures based on their unique physical, thermal, and electrical properties. Selecting the appropriate material requires balancing performance requirements against cost considerations for specific applications.

PEEK: High Heat Resistance and Dimensional Stability

Polyetheretherketone (PEEK) stands as the benchmark among high-performance polymers with exceptional thermal stability. This semicrystalline thermoplastic maintains its mechanical properties at temperatures up to 260°C (480°F) with a melting point around 343°C (649°F). PEEK exhibits remarkable dimensional stability even under prolonged exposure to extreme conditions, making it ideal for precision components. Its semicrystalline structure provides an optimal balance between rigidity and toughness, enabling it to withstand significant mechanical stress. Moreover, PEEK offers excellent radiation resistance, with high-dose gamma rays causing minimal degradation. This combination of properties makes PEEK particularly valuable for aerospace components, medical instruments, and oil and gas applications.

PPS: Chemical Resistance and Flame Retardance

Polyphenylene sulfide (PPS) delivers outstanding heat and chemical resistance at a lower cost than PEEK. With a melting point of 280°C and glass transition point at 90°C, PPS maintains stability in demanding electronic environments. Notably, PPS achieves UL94 V-0 flame resistance without additional flame retardant additives, enhancing safety in electrical applications. Its chemical profile shows remarkable resistance to acids, alkalis, and solvents, with no known solvent capable of dissolving it below 200°C. These properties, combined with its low moisture absorption and precision moldability, make PPS ideal for electronic components requiring dimensional stability during surface mount technology processes.

PEI: Strength-to-Weight Ratio and Machinability

Polyetherimide (PEI), commonly known by the brand name Ultem™, offers an exceptional strength-to-weight ratio that makes it a frequent substitute for metal in various applications. This amorphous polymer operates reliably at temperatures up to 340°F (171°C) while providing excellent dimensional stability. PEI demonstrates good resistance to chemicals, UV light, and weathering, alongside superior hydrolytic stability that allows it to withstand repeated exposure to steam or hot water. Its inherent flame resistance (UL 94-V-0) and minimal smoke output enhance safety in electronic applications.

PTFE: Non-Conductive and Low Friction Properties

Polytetrafluoroethylene (PTFE) provides unmatched electrical insulation with the best dielectric values among all known solids. Its dielectric strength reaches 80 kV/mm (0.125mm thick), making it exceptional for electronic applications. PTFE maintains functionality across an extensive temperature range from -190°C to +260°C. With an extraordinarily low friction coefficient—static COF of 0.05-0.10 and dynamic COF of 0.04-0.08—PTFE facilitates smooth movement in applications requiring minimal friction. This “self-lubricating” material resists adhesion while offering excellent chemical resistance to most substances.

Polycarbonate vs ABS: Impact Strength and Cost Trade-offs

When comparing more accessible enclosure materials, polycarbonate (PC) and acrylonitrile butadiene styrene (ABS) present distinct advantages. Polycarbonate delivers superior impact resistance and withstands higher temperatures, with a heat deflection temperature of approximately 132°C compared to ABS at 97°C. PC naturally filters UV radiation, protecting sensitive internal components even in transparent enclosures. In contrast, ABS offers better resistance to scratches and marring, making it suitable for frequently handled components. The primary trade-off remains cost—ABS provides durable performance at a significantly lower price point than polycarbonate.

Ensure your enclosure design meets electrical and regulatory requirements with the right polymer selection. Request a Material Compatibility Review.

Industry-Specific Requirements for Plastic Housings in Electronics

Different industries demand unique specifications for plastic electronic enclosures based on their operating environments and functional requirements. Each sector faces distinct challenges that directly influence material selection and design considerations.

Semiconductor Applications: ESD Safety and Cleanroom Compatibility

Semiconductor manufacturing environments require exceptional control over electrostatic discharge. Even minimal ESD events of 10 to 20 volts can damage sensitive electronic components. To mitigate this risk, cleanrooms maintain relative humidity between 40% and 60%, creating a slightly conductive film over insulating surfaces. Furthermore, enclosure materials must meet cleanroom standards, with options like Trovidur® EC-FR receiving FM4910 certification for semiconductor applications. This certification verifies flame-retardant properties essential for safety in these controlled environments.

Medical Devices: Biocompatibility and Sterilization Resistance

Medical electronic enclosures must withstand rigorous sterilization processes without degradation. PEEK plastics have gained prominence in this sector due to their excellent biocompatibility and ability to integrate with surrounding tissue. These enclosures regularly undergo steam autoclaving, ethylene oxide sterilization, and gamma radiation. Materials selected must maintain their structural integrity through repeated sterilization cycles while meeting FDA and ISO 10993 biocompatibility standards.

Telecom and Data Centers: Heat Dissipation and EMI Shielding

Telecommunications equipment and data centers face challenges from electromagnetic interference that can corrupt data and damage hardware. Effective EMI shielding requires enclosures that provide 40-100 dB attenuation across multiple frequency bands. Plastic enclosures, though lightweight and cost-effective, require conductive coatings or metal meshes to achieve adequate EMI protection. At this point, cable shielding designs—including braided (effective up to 15 KHz), spiral (for flexibility), and foil shields (for frequencies above 15 KHz)—become crucial for maintaining signal integrity.

Automotive Electronics: Vibration Resistance and Thermal Cycling

Automotive electronic housings must withstand extreme conditions, including temperatures ranging from -40°C to 125°C in engine compartments. Essentially, these components undergo extensive thermal cycling tests, often exceeding 1,000 cycles. High-grade engineering plastics like PPS or PEEK offer dimensional stability at elevated temperatures while resisting degradation from automotive fluids. Materials with low water absorption are prioritized for humid environments, primarily in electronic control units where reliability directly impacts vehicle safety.

Precision Machining and Material Integrity in Enclosure Manufacturing

Manufacturing precision directly impacts how well electronic enclosures protect internal components. The machining process must account for material properties, dimensional specifications, and finishing requirements to ensure optimal performance in demanding applications.

Tight Tolerances for Component Fit and Function

Modern aerospace, medical, and defense applications require polymer components manufactured with tolerances as precise as 0.001 inches. These exacting specifications ensure proper component fit, maintaining critical clearances for electrical isolation and thermal expansion. Achieving consistent tolerances requires sophisticated monitoring systems, targeted post-machining treatments, and precise dimensional control. Multi-axis CNC machines with advanced calibration systems enable manufacturers to maintain tight tolerances, with controlled room temperature further enhancing machining stability.

Surface Finish Requirements for Sealing and Aesthetics

Surface finish, expressed as Roughness Average (Ra) in microinches or micrometers, profoundly affects sealing performance. Lower Ra values indicate smoother surfaces, with most dynamic sealing applications requiring 10-20 microinches for optimal function. Nevertheless, highly polished surfaces aren’t always ideal—some applications benefit from shot-peened or electro-polished surfaces that create microscopic pockets for lubricant retention. For static applications involving liquids, a 32 micro-inch RMS finish is generally adequate, whereas vacuum and gas applications typically require 16 micro-inch RMS finishes.

Avoiding Stress Cracks in Machined Plastics

Stress cracking occurs when tensile stresses—either applied or residual—create internal or external cracks in plastic materials. This issue commonly affects amorphous polymers including acrylic, polycarbonate, and Ultem. Prevention requires knowledge of plastic properties, proper machining techniques, and stress-relieving heat treatments. Controlled annealing processes effectively relieve stress and maintain dimensional stability in finished components.

AIP’s Expertise in High-Performance Plastic Machining

AIP Precision Machining specializes in manufacturing plastic components to extreme tolerances (.002 mm). With over 40+ years of experience, our engineers and machinists deliver unmatched precision through advanced manufacturing technology.

Ensure your enclosure design meets electrical and regulatory requirements with the right polymer selection. Request a Material Compatibility Review.

Conclusion: Optimizing Electronic Enclosure Protection Through Material Selection

Electronic enclosure materials serve as the first line of defense against environmental hazards, electrical interference, and mechanical damage. Throughout this guide, we examined how proper material selection directly impacts system reliability and component longevity. Undoubtedly, dielectric strength remains a fundamental consideration, with materials requiring sufficient voltage withstand capabilities—typically 15 kV or higher—to ensure safety margins in real-world applications.

Additionally, thermal management emerges as equally critical. High-performance polymers like PEEK and PEI maintain dimensional stability at elevated temperatures, therefore protecting sensitive internal components from heat-related degradation. Meanwhile, UL 94 flame ratings provide standardized metrics for assessing fire safety, with classifications ranging from 5VA (highest resistance) to HB (lowest resistance).

Beyond these specifications, industry demands further dictate material selection parameters. Semiconductor applications require exceptional ESD protection and cleanroom compatibility. Medical device enclosures must withstand repeated sterilization while maintaining biocompatibility. Telecom equipment needs effective EMI shielding, whereas automotive electronics must resist vibration and extreme thermal cycling.

Although material selection forms the foundation of protection, manufacturing precision ultimately determines enclosure effectiveness. Tight tolerances—sometimes as precise as 0.001 inches—ensure proper component fit and function. Surface finish specifications directly affect sealing performance, while proper machining techniques prevent stress cracking in finished components.

The optimal enclosure solution, therefore, results from careful consideration of all these factors. Engineers must balance performance requirements against cost constraints while ensuring compliance with relevant standards. Through partnership with experienced manufacturers specializing in high-performance plastics, OEMs can develop enclosure solutions that meet protection standards while advancing product reliability.

FAQs

Q1. What are the key factors to consider when choosing plastics for electronic enclosures?

The main factors include dielectric strength, thermal stability, flame resistance (UL 94 rating), chemical resistance, and compliance with industry-specific standards. Material properties should match the specific operating environment and protection requirements.

Q2. How does PEEK compare to other plastics for electronic enclosures?

PEEK offers exceptional heat resistance, dimensional stability, and chemical resistance. It maintains its properties at high temperatures (up to 260°C) and provides excellent radiation resistance, making it ideal for demanding applications in aerospace, medical, and oil/gas industries.

Q3. What are the advantages of using PEI (Ultem) for electronic enclosures?

PEI offers an excellent strength-to-weight ratio, good machinability, and high temperature resistance (up to 171°C). It also provides inherent flame resistance, UV stability, and superior hydrolytic stability, making it suitable for various electronic applications.

Q4. How important is precision machining in manufacturing electronic enclosures?

Precision machining is crucial for ensuring proper fit, function, and protection of electronic components. Tight tolerances (as precise as 0.001 inches) and appropriate surface finishes are essential for maintaining electrical isolation, thermal management, and sealing performance in enclosures.

Q5. What special requirements do automotive electronic enclosures need to meet?

Automotive electronic enclosures must withstand extreme temperature ranges (-40°C to 125°C), extensive thermal cycling, vibrations, and exposure to automotive fluids. Materials like PPS or PEEK are often used due to their dimensional stability and resistance to degradation in these harsh conditions.