Flame retardant plastics are becoming increasingly vital to aerospace engineering. These specialized materials provide critical fire safety protection in environments where even a small fire can have catastrophic consequences. The difference between achieving a V-0 rating and a V-2 rating under UL 94 standards can determine whether a component proceeds to production or requires costly redesign.

For aerospace applications, flame retardant plastics serve multiple essential functions. They protect sensitive equipment as protective coverings and line cargo holds, fuel storage tanks, engine compartments, and electrical control rooms where fire hazards are present. However, selecting the appropriate material presents significant challenges for engineers. UL 94 ratings are thickness dependent, meaning a resin that passes safety standards at 1.5mm might fail at 0.74mm. Additionally, specialized formulations like polyamide PA 2210 FR have been specifically developed to meet the stringent flammability, smoke, and toxicity standards for civil aerospace, typically qualifying for “flying hardware” with wall thicknesses down to 2mm.

This guide examines the regulatory landscape, material selection criteria, and testing protocols aerospace engineers must navigate when specifying flame retardant plastics. Because these materials improve fire safety but can complicate product end-of-life handling, engineers must balance performance requirements with sustainability considerations. From inherently flame retardant options to additive-based solutions, this article provides a comprehensive framework for making informed material decisions that meet both regulatory requirements and performance needs.

Regulatory Landscape for Aerospace Flame Retardant Plastics

The regulatory framework governing flame retardant plastics in aerospace applications presents a complex landscape that engineers must navigate with precision. Unlike consumer applications, aerospace materials face stringent scrutiny due to the catastrophic consequences of fire events at altitude.

FAA FAR 25.853 and EASA CS-25 Requirements

Federal Aviation Regulation (FAR) 25.853 establishes comprehensive flammability requirements for materials used in aircraft interiors. This standard mandates that materials must self-extinguish rapidly to limit fire spread and produce minimal smoke to reduce visibility and respiratory hazards. The European equivalent, EASA CS-25.853, contains essentially identical requirements, creating a harmonized global standard. Furthermore, China’s Civil Aviation Administration (CAAC) utilizes CCAR 25.853, which mirrors these specifications.

The regulations categorize materials based on their application within the aircraft. For interior ceiling panels, wall panels, and partitions, materials must pass a 60-second vertical burn test where the average burn length cannot exceed 15 cm (6 inches) and the average flame time after removal of the flame source cannot exceed 15 seconds. Meanwhile, floor coverings, textiles, and seat cushions face slightly different criteria with a 12-second vertical burn test where burn length cannot exceed 20 cm (8 inches).

Notably, these requirements vary by aircraft compartment. The Federal Aviation Administration (FAA) introduced Amendments 25-59, 29-23, and 121-184 to require that transport category aircraft be equipped with seat cushions providing enhanced fire resistance, with compliance mandatory after November 26, 1987.

UL 94 vs ASTM E162 and E662

While aerospace-specific standards take precedence, Underwriters Laboratories (UL) 94 testing provides a preliminary indication of a plastic’s flammability characteristics. UL 94 contains multiple test methods: 94HB (Horizontal Burn), 94V (Vertical Burn), 94VTM (thin materials), 94-5V (enclosures), 94HBF/HF (foams), and Radiant Panel.

The classifications range from 5VA (most flame retardant) to HB (least flame retardant). For instance, V-0 rated materials must stop burning within 10 seconds after flame application with no flaming drips allowed, whereas V-2 materials can burn up to 60 seconds and permit flaming drips.

In contrast, ASTM E162 (Radiant Panel Test) measures surface flammability using a radiant heat source. This small-scale test determines a flame spread index and is often required for mass transit and railway applications. ASTM E662, conversely, quantifies smoke density by measuring light attenuation in a closed chamber under both flaming and non-flaming conditions.

Material Compliance Documentation for Aerospace and Defense

Documentation serves as the cornerstone of regulatory compliance in aerospace applications. Each material must have associated test reports demonstrating adherence to relevant standards. Primarily, compliance with FAR/CS 25.853 must be maintained throughout the aircraft’s operational life, including after cabin upgrades or refurbishments.

For material approval, a Supplemental Type Certificate is not necessary; instead, a letter of FAA engineering approval is considered adequate. However, all documentation must be properly archived and readily traceable to each material or part number in use.

During certification, it’s essential to note that each set of specimens must pass weight loss and burn length criteria independently. For example, in accordance with Part 25, Appendix F—Part II, paragraph (a)(4), burn length may not exceed 17 inches on at least two of the specimen sets.

Engineers selecting flame retardant plastics for aerospace applications must thoroughly understand these regulatory requirements and ensure proper documentation throughout the material’s lifecycle to avoid costly compliance issues later.

Material Selection Criteria Based on Application Zones

Selecting appropriate flame retardant plastics for aerospace applications requires engineers to consider specific performance requirements based on where components will be installed. Different zones within an aircraft present unique challenges that demand tailored material solutions.

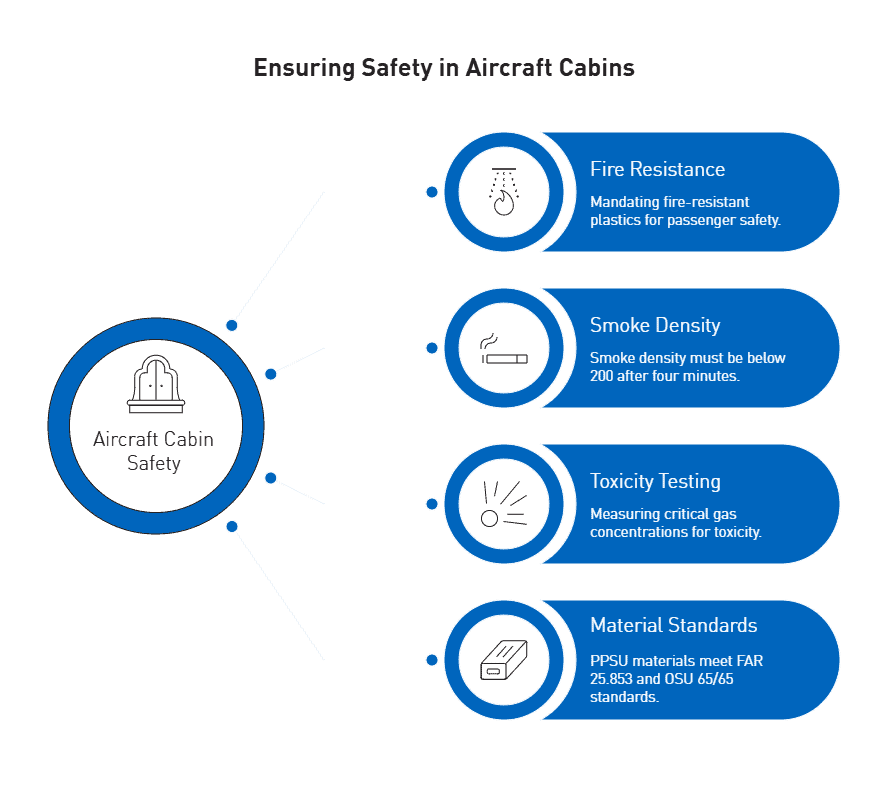

Cabin Interiors: Low Smoke and Toxicity Requirements

The aircraft cabin environment demands materials that prioritize passenger safety during fire events. Following the late 1980s FAA statistics showing approximately 40% of survivors from impact-related crashes died from post-crash fire and smoke exposure, stringent regulations were implemented in 1987 mandating fire-resistant plastics in all passenger planes.

Cabin interior materials must meet comprehensive Fire, Smoke, and Toxicity (FST) requirements. Smoke density tests require values below 200 after burning for four minutes. Equally important, toxicity testing measures concentrations of critical gasses including:

- Carbon monoxide (CO)

- Hydrogen cyanide (HCN)

- Hydrogen fluoride (HF)

- Hydrogen chloride (HCl)

- Sulfur dioxide (SO2)

- Nitrogen oxides (NOx)

Polyphenylsulfone (PPSU) materials like Solvay’s RADEL® have become industry standards for cabin applications, offering exceptional toughness alongside meeting FAR 25.853 requirements. These materials deliver better impact resistance and chemical stability than other sulfone-based polymers while meeting the OSU 65/65 heat release standards.

Engine Compartments: High Heat and Chemical Resistance

Engine compartment applications present substantially different challenges than cabin interiors, primarily requiring exceptional thermal stability alongside flame retardance. Materials in these zones must withstand continuous operating temperatures above 200°C while maintaining structural integrity.

Polyphenylene sulfide (PPS) stands out for engine compartment applications with its melting point exceeding 280°C and heat distortion temperature above 260°C. Moreover, this material offers long-term use capability between 220-240°C. PPS degrades very slowly at high temperatures, remaining stable for extended periods in air at 200°C, and maintaining 40% of its weight even in inert gas at 100°C.

Besides heat resistance, PPS provides inherent flame retardance without additional additives, achieving UL94 V-0 classification. This self-extinguishing property prevents fire propagation in critical engine zones where fuel and ignition sources coexist.

Electrical Housings: Dielectric Strength and Flame Retardance

Electrical components present unique demands, requiring materials that combine electrical insulation properties with flame retardance. The ideal insulation for higher voltage aerospace systems must be lightweight, chemically stable, and provide good corona suppression while withstanding high voltages.

Dielectric strength—the maximum voltage an insulating material can withstand before breakdown—is expressed as voltage per unit thickness (volts/mil). This property becomes crucial in aerospace applications where high voltage systems operate in confined spaces with minimal insulation thickness.

Wire and cable insulation throughout the aircraft commonly uses thermosetting resins and thermoplastics. For general applications inside the pressure shell, high-performance wire jacketing typically includes radiation cross-linked poly(ethylene-tetrafluoroethylene) (ETFE) and composite constructions with poly(tetrafluoroethylene) (PTFE). In higher temperature and fuel areas, PTFE sees almost exclusive use, while filled PTFE provides superior burn-through resistance for the most demanding applications.

Electrical housings must also maintain their dielectric properties after extended environmental exposure. This requirement makes material selection particularly challenging, as engineers must balance electrical performance with mechanical properties and flame retardance across a wide temperature range.

Overview of Inherently Flame Retardant and Additive-Based Plastics

Aerospace engineers must navigate two primary categories of flame retardant plastics: those with inherent flame resistance and those requiring additives to achieve suitable fire protection. Each approach presents distinct advantages and limitations for critical aerospace applications.

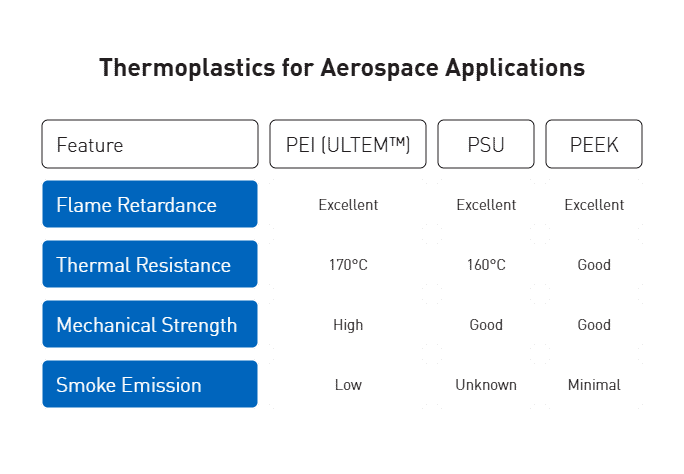

Inherently Flame Retardant Plastics: PEI, PSU, PEEK

High-performance thermoplastics with built-in flame resistance offer significant advantages in aerospace applications. Polyetherimide (PEI), commonly known as ULTEM™, stands out with its exceptional thermal properties and inherent flame retardance. PEI achieves UL 94V-0 and 5VA flammability ratings without requiring any flame retardant additives. With a continuous service temperature of 170°C coupled with high mechanical strength, PEI has become a preferred material for aircraft interiors due to its low smoke emission characteristics.

Polysulfone (PSU) shares many characteristics with PEI, though with slightly lower thermal resistance (160°C versus 170°C). Nevertheless, PSU still offers excellent flame retardance for less thermally demanding applications.

PEEK (polyetheretherketone) similarly performs well under fire conditions while producing minimal smoke density among comparable materials. This inherent flame resistance makes these polymers particularly valuable for applications where additive-free solutions are preferred.

Flame Retardant Additives for Plastics: Brominated vs Halogen-Free

When inherently flame-resistant polymers aren’t suitable, engineers turn to additive approaches. These additives function through distinct mechanisms:

- Vapor phase inhibition: Halogenated additives disrupt combustion at the molecular level

- Solid phase char-formation: Creates an insulating carbonaceous layer

- Quench and cool: Releases water molecules that cool the polymer

Brominated flame retardants (BFRs) represent approximately 30% of global flame retardant production by volume. Though effective at relatively low concentrations, these additives face increasing scrutiny due to environmental persistence.

Consequently, phosphorus-based alternatives have gained prominence. Organophosphorus flame retardants account for roughly 20% of global production. Modern phosphinate-based solutions like Exolit™ OP provide high flame retardancy while maintaining mechanical properties throughout the product lifecycle.

Trade-offs Between Additive Load and Mechanical Properties

The relationship between additive concentration and mechanical performance presents critical engineering trade-offs. Most polymers require approximately 20% minimum filler content to show appreciable flame retardancy improvement, with typical loadings of 50-60%. Unfortunately, such high concentrations often compromise mechanical integrity.

This relationship isn’t always straightforward, though. In certain formulations, additives like tetrabromobisphenol A (TBBPA) at 10-20% concentration actually improved compressive strength by 22-29% while simultaneously enhancing flame retardance. Similarly, TBBPA increased abrasion resistance by over 200% in some composites.

For aerospace applications where mechanical requirements are stringent, engineers must carefully balance flame retardance with structural integrity. Halogen-free intumescent formulations often require higher loading than their halogenated counterparts to achieve equivalent performance, thereby presenting greater mechanical property challenges.

Testing Protocols and Certification Pathways

The certification process for flame retardant plastics in aerospace requires rigorous testing protocols that validate material performance under controlled fire conditions. Successful navigation through these pathways demands thorough understanding of test configurations and their relationship to real-world applications.

Vertical and Horizontal Burn Test Configurations

Vertical burn testing represents the cornerstone of aerospace flammability certification. According to FAA requirements, specimens must be rectangular (minimum 3 by 12 inches or 75 by 305 mm) and mounted vertically in a draft-free cabinet. The 60-second vertical test mandates that materials self-extinguish within 15 seconds after flame removal, with average burn length not exceeding 6 inches (152 mm). In contrast, the 12-second vertical test allows a slightly longer 8-inch (203 mm) maximum burn length.

Horizontal burn testing evaluates materials’ flame spread characteristics when oriented horizontally—an arrangement that better simulates certain in-service conditions. This test applies a standardized flame for 15 seconds to one edge of the specimen. Materials pass if their burn rate remains below specified thresholds: 2.5 inches/minute for FAR 25.853(b-2) or 4 inches/minute for FAR 25.853(b-3).

Thickness-Specific Certification Challenges

Material thickness significantly impacts flame retardance performance and certification outcomes. As the factual data indicates, a resin passing at 0.059 inches (1.5mm) may fail entirely at 0.029 inches (0.74mm). This thickness dependence creates substantial challenges for aerospace engineers designing thin-walled components.

UL 94 classifications clearly demonstrate this thickness-performance relationship:

- Parts ≥3.0mm thick can achieve 5VA ratings (highest protection)

- Parts ≥1.5mm thick may qualify for 5VB ratings

- Parts ≥0.75mm typically achieve V-0 ratings

- Parts ≥0.4mm often limited to V-2 ratings

Role of Third-Party Labs and Material Suppliers

Independent laboratories provide critical verification services throughout the certification process. These facilities maintain specialized equipment including draft-free test cabinets, calibrated burners, and precise measurement tools. Many labs maintain active approvals from major aerospace manufacturers like Boeing and Airbus.

Material suppliers likewise play an essential role by providing UL Yellow Cards—certifications confirming materials have undergone comprehensive safety testing. These documents specify exact formulations and applicable thickness ranges, serving as crucial reference points during material selection.

Given testing variability between facilities, engineers should carefully consider laboratory credentials, especially since small differences in test execution can significantly impact results. Throughout certification, close collaboration between engineers, testing laboratories, and material suppliers remains essential for navigating the complexities of flame retardant certification.

Sustainability and Environmental Considerations

Environmental and health concerns surrounding traditional flame retardants are reshaping material selection criteria for aerospace applications. As regulatory landscapes evolve, engineers must consider sustainability alongside performance metrics.

PFAS in Flame Retardant Additives: Regulatory Trends

The regulatory environment for per- and polyfluoroalkyl substances (PFAS) has tightened significantly. In April 2024, the EPA designated PFOA and PFOS as hazardous substances under the Comprehensive Environmental Response, Compensation, and Liability Act. Subsequently, regulators established maximum concentration levels at 4 parts per trillion for PFOA and PFOS, and 10 ppt for PFHxS, PFNA, and GenX Chemicals.

Despite these restrictions, the aerospace industry remains highly dependent on PFAS for critical applications. Currently, many proposed exemptions for transport applications exist, yet these remain insufficient for comprehensive aerospace needs. Industry experts estimate complete PFAS replacement could take decades.

Recyclability of Flame Retardant Thermoplastics

Flame retardant materials present significant recycling challenges. Thermoplastics treated with flame retardants typically undergo only thermal recycling, as chemical separation proves difficult. Thereafter, identifying and separating different thermoplastic types becomes problematic, as each material has unique chemistry and recycling prospects.

Promising developments include mono-material approaches using polyurethane resin. Unlike conventional epoxy resins, PUR enables chemical recycling through solvolysis, recovering both the polyol fraction and carbon fibers from CFRP components. Second-life applications for recycled aerospace thermoplastics include warehouse trays, conveyor systems, and outdoor equipment housings.

Non-Halogenated Alternatives and Green Certifications

Non-halogenated flame retardants have emerged as environmentally preferable alternatives. Phosphorus-based systems, generally non-toxic and effective at char formation, have established an environmentally friendly profile. Presently, mineral-based additives are gaining traction as “green” solutions.

Bio-based flame retardants derived from lignin, starch, chitosan, and phosphorus compounds effectively reduce heat release and smoke emission. For aerospace applications specifically, products like Melapur flame retardants offer halogen-free solutions without antimony or heavy metals.

Major suppliers including Clariant have developed phosphinate-based technologies like Exolit OP that maintain performance properties throughout product lifecycle and after recycling. First, these solutions provide high flame retardancy; second, they maintain mechanical strength; third, they offer proven recyclability. This transition toward sustainability aligns with broader industry efforts to balance fire safety with environmental responsibility.

Conclusion

Aerospace engineers face multifaceted challenges when selecting flame retardant plastics for critical applications. Throughout this guide, we explored how regulatory frameworks fundamentally shape material selection decisions. FAA FAR 25.853, EASA CS-25, and UL 94 standards establish clear performance thresholds that materials must meet before consideration for aerospace applications. These requirements vary significantly based on installation location, from cabin interiors demanding low smoke and toxicity to engine compartments requiring exceptional thermal stability.

Material selection accordingly requires careful evaluation of application-specific needs. Cabin components demand materials like polyphenylsulfone (PPSU) that meet stringent FST requirements, while engine compartments benefit from polyphenylene sulfide (PPS) with its superior heat resistance. Electrical housings, meanwhile, need materials balancing dielectric strength with flame retardance properties.

The dichotomy between inherently flame retardant polymers and additive-based solutions presents another critical decision point. High-performance thermoplastics such as PEI, PSU, and PEEK offer built-in flame resistance without additives, albeit at higher material costs. Conversely, additive-based approaches provide more flexibility but often necessitate trade-offs between flame retardance and mechanical properties.

Testing protocols further complicate material selection. Engineers must recognize that vertical and horizontal burn tests yield different results, while material thickness significantly impacts certification outcomes. Close collaboration with third-party laboratories and material suppliers therefore becomes essential for navigating these complexities.

Sustainability considerations undoubtedly influence modern material selection decisions. Regulatory trends restricting PFAS usage, coupled with growing emphasis on recyclability, push engineers toward non-halogenated alternatives and bio-based flame retardants. Though environmental regulations continue evolving, aerospace applications still require exemptions due to their uniquely demanding performance requirements.

Effective flame retardant plastic selection ultimately requires balancing multiple competing factors: performance requirements, regulatory compliance, weight constraints, cost considerations, and environmental impact. Engineers must evaluate these factors systematically rather than focusing solely on fire performance. This comprehensive approach ensures selected materials not only meet immediate certification requirements but also remain viable throughout the aircraft’s operational lifespan despite evolving regulations and environmental standards.

FAQs

Q1. What are the key regulatory standards for flame retardant plastics in aerospace?

The main standards are FAA FAR 25.853 and EASA CS-25, which set requirements for flammability, smoke emission, and toxicity. UL 94 ratings are also commonly used to classify flame retardant performance.

Q2. How do material requirements differ for various aircraft zones?

Cabin interiors need materials with low smoke and toxicity. Engine compartments require high heat and chemical resistance. Electrical housings must balance dielectric strength with flame retardance.

Q3. What are the advantages of inherently flame retardant plastics?

Inherently flame retardant plastics like PEI, PSU, and PEEK offer built-in fire resistance without additives. This can result in better overall performance and fewer environmental concerns compared to additive-based solutions.

Q4. How does material thickness affect flame retardant certification?

Material thickness significantly impacts flame retardance performance. A plastic that passes certification at one thickness may fail at a lower thickness, creating challenges for designing thin-walled components.

Q5. What sustainability trends are impacting flame retardant plastic selection?

There’s a growing shift towards non-halogenated and bio-based flame retardants due to environmental concerns. Recyclability is also becoming more important, though it remains challenging for many flame retardant materials.