Additive Manufacturing

Expanding Our Capabilities with 3D Printing Precision

AIP is committed to advancing precision manufacturing by integrating cutting-edge technologies that meet the demands of high-performance industries. With the addition of the Roboze ARGO 500, AIP now offers additive manufacturing capabilities for high-strength polymer components. This investment enhances our ability to produce complex geometries, lightweight structures, and high-performance parts while maintaining the same standards of precision, reliability, and material expertise that define AIP’s machining excellence.

Capabilities

Capabilities

The Roboze ARGO 500 enables AIP to manufacture functional, end-use components using high-performance polymers and composites. Our additive manufacturing capabilities now include:

- Large-Format Printing: Build dimensions of 500 x 500 x 500 mm, allowing for the production of sizable components without compromising structural integrity.

- High-Temperature Materials: Processing of advanced polymers like PEEK, Carbon PEEK, ULTEM™ AM9085F, and Carbon PA for applications requiring extreme heat, chemical, and wear resistance.

- High-Precision Tolerances: The beltless direct drive system of the ARGO 500 ensures mechanical repeatability down to 10 microns, meeting the stringent tolerances required by aerospace, medical, and semiconductor industries.

- Fully Controlled Printing Environment: Heated chamber up to 356°F for optimal crystallization, mechanical strength, and dimensional accuracy of printed components.

- Production-Ready Parts: Additive manufacturing at AIP provides rapid prototyping and low-to-medium volume production, accelerating product development while reducing material waste.

Industries

AIP’s expansion into additive manufacturing strengthens our ability to serve industries that demand high-performance polymer components with complex geometries.

- Aerospace & Defense: Lightweight, heat-resistant polymer components for aircraft interiors, UAV structures, and high-strength defense applications.

- Medical & Life Sciences: Custom medical devices, sterilizable surgical guides, and patient-specific components made from biocompatible materials.

- Power & Energy: Chemical-resistant and high-strength parts for downhole drilling, industrial, and fluid-handling applications.

With additive manufacturing, AIP delivers engineered solutions tailored to industry-specific requirements, maintaining our focus on material expertise and application-driven precision.

Technology

The ARGO 500 represents a significant advancement in thermoplastic additive manufacturing, providing industrial-scale production of polymer components with unmatched mechanical performance.

- Advanced Polymer Extrusion: The extrusion system reaches 450°C, allowing for precise control of high-performance materials.

- Automated Material Control: Drying and preheating systems ensure optimal material conditions before and during printing, preventing moisture-related defects.

- Smart Process Control: Integrated sensors monitor temperature, extrusion flow, and chamber conditions, ensuring consistency and repeatability.

- Sustainability & Efficiency: Additive manufacturing minimizes material waste compared to subtractive machining, supporting cost-effective and environmentally responsible production.

By leveraging this advanced technology, AIP enhances its ability to engineer complex polymer components with superior performance characteristics.

Precision

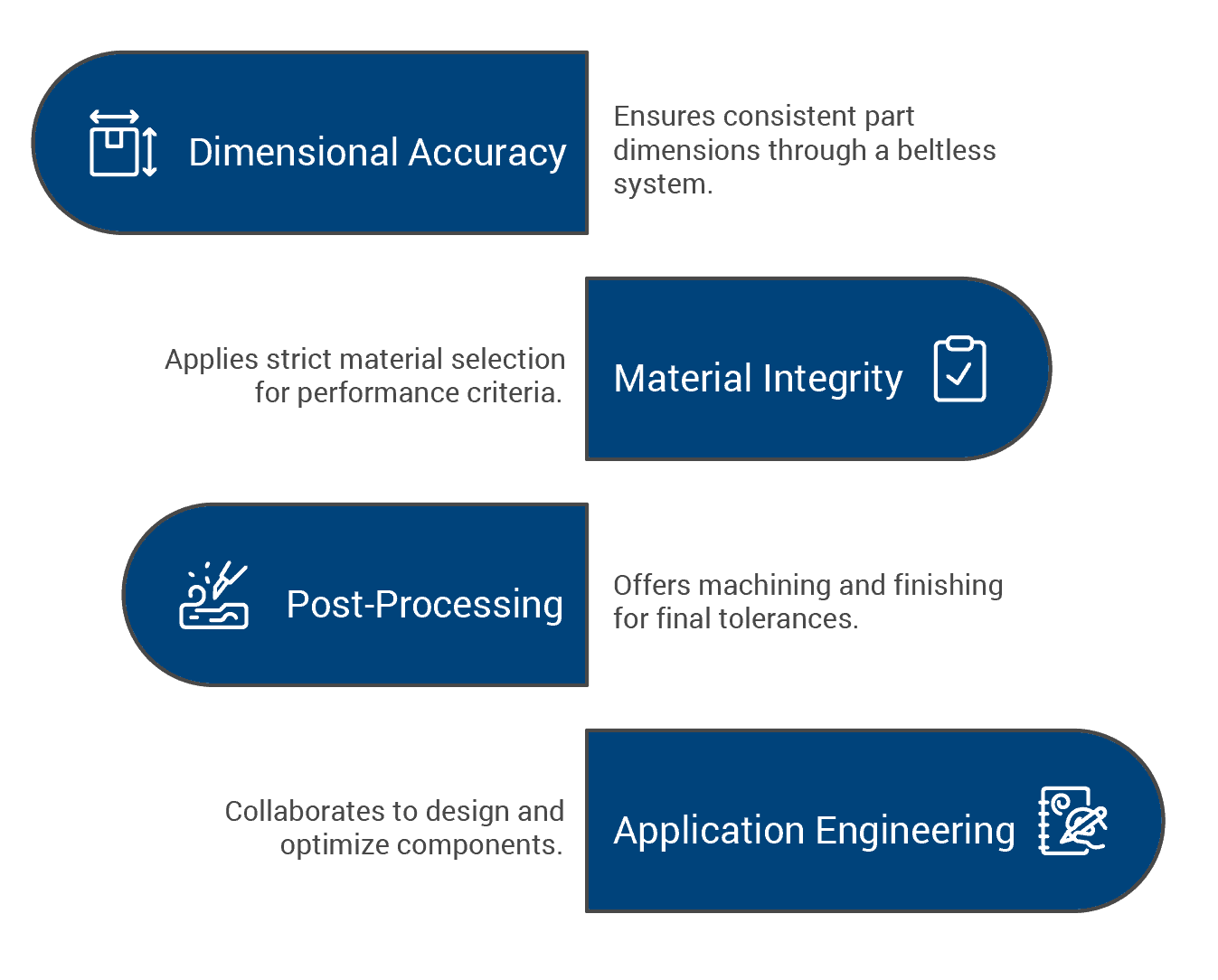

AIP has built a reputation on ultra-tight tolerances, material expertise, and quality assurance. Our integration of additive manufacturing follows the same principles that define our precision machining capabilities:

- Dimensional Accuracy: The ARGO 500’s beltless system eliminates mechanical inaccuracies, ensuring consistent part dimensions.

- Material Integrity: AIP applies strict material selection and process validation to ensure each component meets its intended performance criteria.

- Post-Processing & Quality Control: We offer post-print machining, annealing, and finishing to achieve final tolerances and surface quality required for critical applications.

- Application-Specific Engineering: AIP collaborates with customers to design, prototype, and optimize polymer components for demanding environments.

With decades of expertise in high-performance polymers, AIP now combines precision machining with additive manufacturing, offering customers a broader range of engineered polymer solutions.

Partner with AIP for High-Performance Additive Manufacturing

AIP’s additive manufacturing capabilities enable the next generation of high-performance polymer components. Whether you need complex geometries, lightweight structures, or production-ready parts, AIP’s expertise in material science and precision manufacturing ensures exceptional quality and performance.

For more information or to discuss your application, contact AIP today.

Partnered with Leading Plastics Companies

We print material bases supplied by several vendors.

Discover Our SuppliersThe best thing for us about AIP is their quality and material expertise. They have an ability to come up with what we need when we can’t make it work ourselves.

Senior BuyerTeledyne Oil and Gas

We Know How to Tackle Any Project

With 35+ years of experience, we can handle any geometry and any challenge.